Interpreting The Results Of The Engine Compression Test

The cylinders will eventually suffer wear and tear (as the engine accumulates miles) and produce lower compression values. This doesn't happen overnight, but it will happen.

Now, uneven compression across the cylinders will not cause engine performance problems if the variation (in the compression values) does not vary more than 15%.

If in TEST 1 some of the cylinders have a lower compression value than the rest, then this section will help you figure out if those compression values are lower than 15% of the highest value. Because if they are, they are causing a problem.

There are one of two ways to find out: You can calculate this 15% difference with pen and paper or you can use my low compression calculator. You can find the low compression calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that my engine compression test produced the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Engine Compression Test.

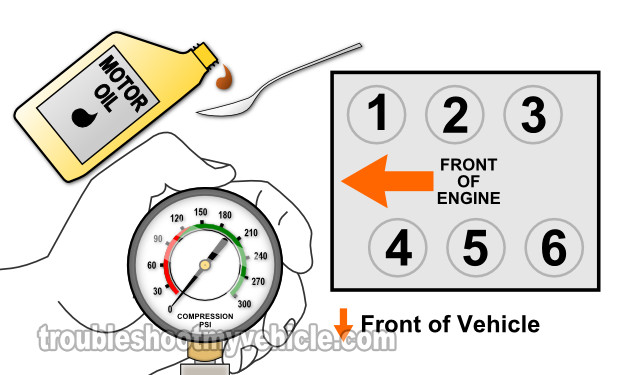

TEST 2: ‘Wet’ Engine Compression Test

You might be asking yourself, “What's a Wet Compression Test?”, it's the same compression test you did before with the difference being that you're gonna' add about two tablespoons of oil to the engine cylinder that showed a low compression reading in the ‘Dry’ compression test.

The engine oil that you're gonna' add to the cylinder will help determine if the low cylinder pressure or pressures you recorded in the ‘Dry’ compression test are caused by worn piston rings or worn cylinder head valves.

Depending on whether the compression pressure rises (on your compression tester) or not, you'll be able to say that the problem lies in the piston's rings or in the cylinder head valves.

OK, this is what you need to do:

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the ‘dry’ compression test.

The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder. Do not use any type of tool to tightened the compression tester. Hand tight is fine.

- 3

When all is set up, have your helper crank the engine.

- 4

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before).

2.) The compression value will stay the same.

Let's take a look at your test results:

CASE 1: The compression value shot up. This tells you that the piston compression rings are worn out and thus the problem is in the bottom end (block) of the engine in your 3.0L/3.8L Ford vehicle.

CASE 2: The compression value stayed the same. This test result tells you that the low compression in this specific cylinder is due to bad cylinder head valves.

Why An Engine Compression Test?

This is one of the most overlooked tests to find the root cause of a misfire code, rough idle or an engine miss or a blown head gasket.

Over the years, I have solved many unsolvable misfire codes, rough idle, lack of power issues by doing a simple engine compression test and if you're faced with something similar, I highly recommend doing an engine compression test.

More 3.0L, 3.8L Diagnostic Tutorials

You can find a complete list of 3.0L, 3.8L Ford diagnostic tutorials in this index: Ford 3.0L, 3.8L Index Of Articles.

If this tutorial did not help you solve your misfire condition, misfire code, or rough idle condition, I recommend taking a look at the following specific Ford V6 article(s):

At easyautodiagnostics.com, you'll find the following articles:

- How To Test The Ford V6 Ignition Coil Pack.

- How To Test The Ignition Control Module (Older 3.0L And 3.8L With A Distributor).

- How To Test The MAF Sensor.

- How To Test The Throttle Position Sensor (TPS).

If this info saved the day, buy me a beer!