TEST 1: Testing The Throttle Position Signal With A Multimeter

When the throttle plate in the throttle body is closed on the 1994-1995 3.0L Ford Taurus (3.0L Mercury Sable), the throttle position sensor produces a voltage of about 0.5 Volts DC.

This voltage increases as the throttle plate opens. When the throttle plate opens too it's completely open position, the sensor generates a voltage of about 4.5 volt DC.

So, in this section we are going to connect a multimeter to the throttle position sensors metal wire to see if it's generating the correct signal as we open and close the throttle plate.

NOTE: The TPS has to remain connected to its electrical connector to be able to read the throttle position signal. For this reason, you're gonna need a back-probe tool or a wire piercing probe. To see an example of a wire piercing probe, check out this link: Wire Piercing Probe (at: easyautodiagnostics.com).

Here are the test steps:

- 1

Place your multimeter in Volts DC mode.

- 2

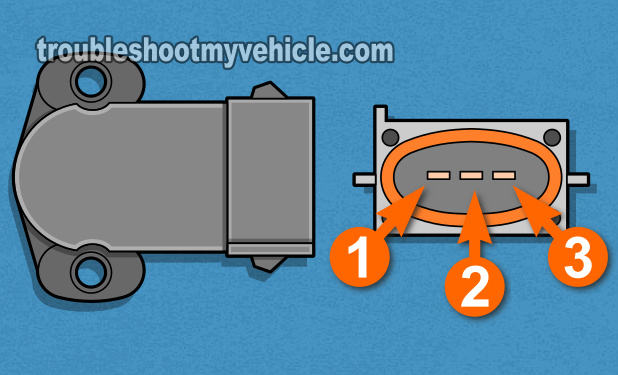

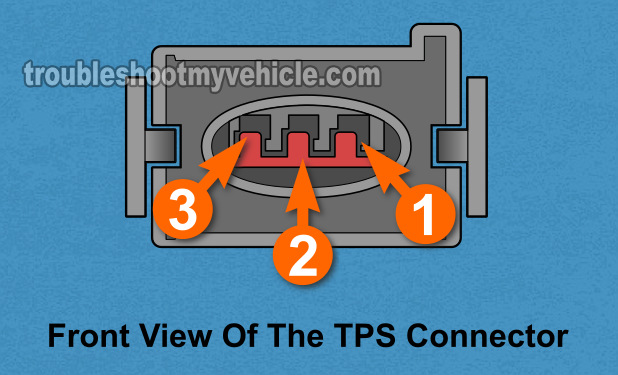

Connect the red multimeter test lead to the wire that connects to the terminal labeled with the #2.

NOTE: The TP sensor connector needs to be connected to the TPS, so you'll need to either back-probe the connector or use a wire piercing probe to get to the signal inside the wire (to see what a wire piercing probe looks like: Wire Piercing Probe Tool). - 3

Ground the black multimeter test lead directly on the battery negative (-) post.

- 4

Turn the key on but don't crank or start the engine. This will power up the TPS.

- 5

Manually rotate the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 6

The multimeter should show an increasing voltage as you (or your helper) open up the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 7

The multimeter should show a decreasing voltage as you begin to close the throttle.

- 8

Using a screwdriver's handle, gently tap the TP sensor as you open and close the throttle and observer the multimeter.

The purpose (of tapping the TP sensor with the screwdriver's handle) is to see if the TP sensor shows gap's in the voltage signal. Why? Because a good TP sensor will show a continuous increasing or decreasing voltage signal even while getting tapped by the screw-driver's handle.

Let's take a look at your test results:

CASE 1: The TP sensor signal's voltage increased or decreased smoothly and without gaps. This is the correct and expected test result and lets you know that the throttle position sensor, on your 1994-1995 3.0L Ford Taurus, is OK. This test result also tells you that the TPS is getting Ground and Power.

CASE 2: The TP sensor signal's voltage DID NOT increase or decrease smoothly and/or showed gaps. This test result usually tells you that the throttle position sensor (TPS) is fried and needs to be replaced but not always.

We need to do one more test to make sure and that's to verify that the TP sensor is getting both power and Ground. For this test, go to: Making Sure The TPS Is Getting Power And Ground.

TEST 2: Making Sure The TPS Is Getting Power And Ground

If you've reached this point, then the throttle position sensor on your 3.0L Ford Taurus failed TEST 1.

So, in this section we're going to make sure that the TPS is getting 5 Volts and Ground.

5 Volts are fed to the TPS through the cable that connects to the male spade terminal labeled with the #1 in the illustration above.

Ground is fed to the TPS through the cable that connects to the male spade terminal of the TPS identified with the #3 in the illustration above.

IMPORTANT: Be careful not to pass 12 Volts (from the battery) to the Ground circuit (wire) of the TPS connector, or you'll fry the fuel injection computer. The multimeter voltage test I'm suggesting below is a safe way to check for the presence of Ground in the wire.

Here are the test steps:

- 1

Check circuit #1 for 5 Volts DC with the Key On Engine Off (KOEO).

A.) Connect your multimeter's red test lead to the wire that connects to the male terminal labeled with the #1.

B.) Connect the black multimeter test lead to the battery negative (-) post.

C.) The multimeter should register between 4.5 to 5 Volts DC. - 2

Check circuit #3 for Ground with the Key On Engine Off (KOEO).

A.) Connect your multimeter's black test lead to the wire that connects to the male terminal labeled with the #3.

B.) Connect the red multimeter test lead to the battery positive (+) post.

C.) The multimeter should register 10 to 12 Volts DC if Ground is present in the wire.

Let's take a look at your test results:

CASE 1: Both Ground and power (5 Volts) are present. This is the correct and expected test result.

Since you have now confirmed (in TEST 1) that the TP sensor is not producing a signal and in this test you've confirmed that the sensor is getting both power and Ground, you can conclude the TP sensor is bad and needs to be replaced.

CASE 2: Either Ground or power ARE NOT present. This test result exonerates the TP sensor as being bad and tells you that the reason the TP sensor is not producing an increasing/decreasing voltage signal in TEST 1 is because it's missing power or Ground.

Although it's beyond the scope of this tutorial, you'll need to find out why this signal is missing to get the TP sensor back on the job.

TPS Trouble Code Won't Go Away

In certain cases, the fuel injection computer continues to set a throttle position sensor diagnostic trouble code even though the sensor is brand new (or you've already checked it's working correctly with a multimeter).

If this is what's happening in your particular case, then the following suggestions should help you to resolve the problem:

- Check the adjustment of the throttle plate stop set screw.

- This screw's adjustment usually has been altered to idle up the engine and mask a rough idle condition. The PCM doesn't like it when this is done and sets a TP sensor code.

- Check the continuity of the TP sensor's wires (between the PCM and the TP sensor connector).

- If there's a break in any of the 3 wires, the PCM will set a TP sensor code.

- Check for a bad fuel injection computer (PCM).

- Is there a way to test for a bad PCM? Yes and no. The only way to test for a bad PCM is to test it indirectly. This is what I do to test for a bad PCM (with about a 98% success rate):

- Eliminate the TP sensor itself as bad.

- Check the continuity of the 3 TP sensor wires (between the PCM and the sensor). The idea here is to make that none of the TP sensor wires are cut (‘open’).

- Check all of the PCM Ground wires by doing a voltage drop test on them. This simply involves checking the Ground wire for voltage (not Ohms) with the Key On Engine Off. There should be no voltage on the wire. If there's voltage (2 Volts or more) that specific Ground wire is not providing a good path to Ground and it means you need to clean the Ground terminals and/or check their condition.

- Check that the PCM is getting power on the all of it's power circuits.

- After eliminating the TP sensor, a problem in the 3 TP sensor wires (between the PCM and sensor), eliminating the PCM's Ground wires, and verifying the PCM is getting power on all its power circuits, then, and only then I can say with confidence that the PCM is bad.

- Is there a way to test for a bad PCM? Yes and no. The only way to test for a bad PCM is to test it indirectly. This is what I do to test for a bad PCM (with about a 98% success rate):

If this info saved the day, buy me a beer!