The throttle position sensor (TPS) in the 1994 through 1995 3.8L Ford Taurus (Mercury Sable) can be tested easily.

The test involves three specific steps. In the first one, we're gonna' make sure that the TPS is producing a TP signal that corresponds to the throttle plate angle.

The other two tests are to make sure that the TPS is receiving 5 Volts and Ground. From the results of these 3 tests, you'll be able to correctly conclude that the TPS is defective or not.

NOTE: This tutorial also applies to the TPS of the 1994-1995 3.8L V6 Mercury Sable and 1995 3.8L V6 Ford Windstar mini-van.

Contents of this tutorial:

ES ![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor TPS (1994-1995 3.8L Taurus) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor TPS (1994-1995 3.8L Taurus) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Taurus: 1990, 1991, 1992, 1993, 1994, 1995.

- 3.8L V6 Mercury Sable: 1990, 1991, 1992, 1993, 1994, 1995.

MAF SENSOR TESTS:

3.0L V6 TAURUS/SABLE, AND RANGER: The TPS sensor test for the 3.0L V6 Taurus, Sable, and Ranger -and- the 3.8L V6 Windstar can be found here:

- How To Test The TPS With A Multimeter (1991-1995 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The TPS (1993-1994 3.0L Ford Ranger) (at: easyautodiagnostics.com).

Symptoms Of A Defective TPS

Your 3.8L Ford Taurus' fuel injection computer needs to know the throttle plate angle to effectively manage engine performance.

This throttle plate angle changes continually as you step on or off the accelerator pedal (since the accelerator pedal is connected to the throttle bodies throttle plate via an accelerator cable).

The fuel injection computer uses this information (throttle angle), along with other sensor inputs, to: inject more/less gasoline, advance/retard ignition timing, etc.

So, when the throttle position sensor fails, your Ford Taurus' engine performance will suffer and you're gonna' see one of the following symptoms:

- The check engine light (CEL) lit by one or more of the following trouble codes stored in the computer's memory.

- 43: Throttle Position (TP) Sensor Below Idle Specification.

- 53: Throttle Position (TP) Sensor Above Maximum Voltage.

- 63: Throttle Position (TP) Sensor Below Minimum Voltage.

- Bad gas mileage.

- Lack of power when you accelerate the vehicle down the road.

- The engine hesitates when you accelerate the engine under load.

Where To Buy The TPS And Save

The throttle position sensor for 1994-1995 3.8L V6 Ford Taurus (Mercury Sable) isn't an expensive component. Still, never hurts to save a few bucks. So with that in mind, the following links will help you to comparison shop for the TP sensor.:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above TPS is the correct one for your Ford Taurus (Mercury Sable)? No worries, once you get to the site, they'll ask you for your vehicle's specific information and check that that fits. If it doesn't, they'll find you the right one.

TEST 1: Testing The TP Signal With A Multimeter

The very first test, we're gonna' do is verify that the TPS is producing a signal that changes with the throttle plate angle.

Here's what we're looking for:

- Closed throttle: With the throttle plate fully closed, the TPS should produce a voltage between 0.5 and 0.9 Volts DC.

- Wide open throttle: As you open the throttle plate, the voltage should increase steadily until it reaches about 4.5 to 4.9 Volts DC at wide open throttle.

So, what we'll do is measure the TPS signal voltage with the throttle closed, then slowly open it while watching for a smooth voltage increase as the throttle moves toward its fully open position.

If the TPS is defective, you'll usually see that the voltage stays stuck at one value, no matter how much you move the throttle plate.

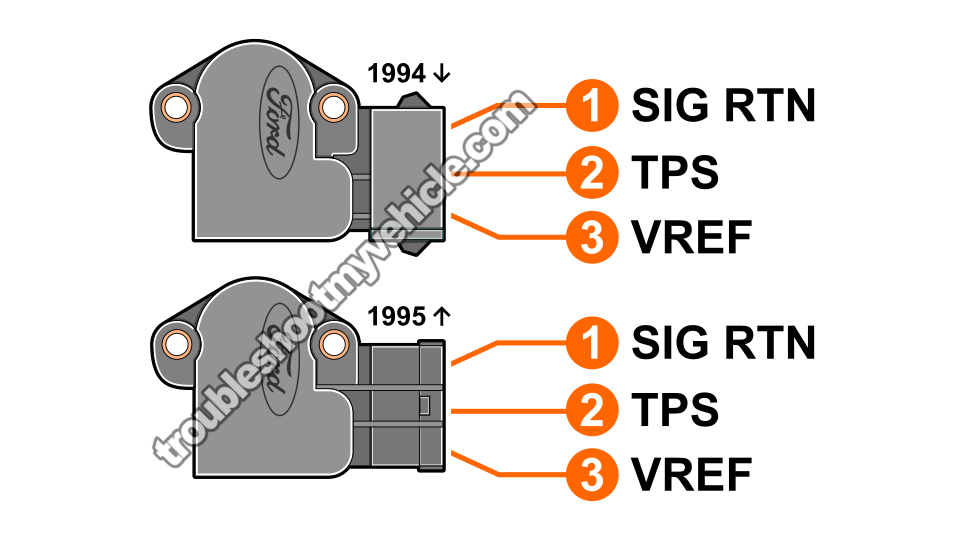

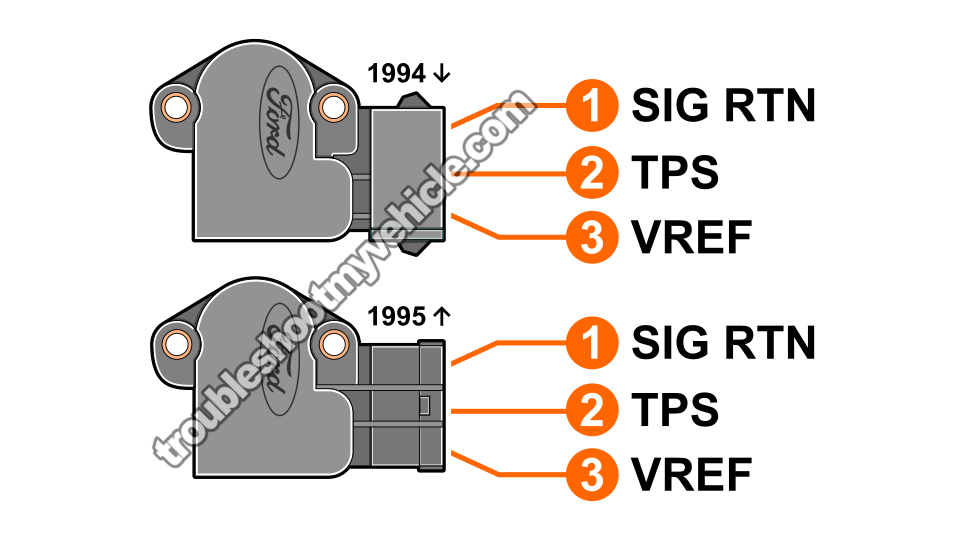

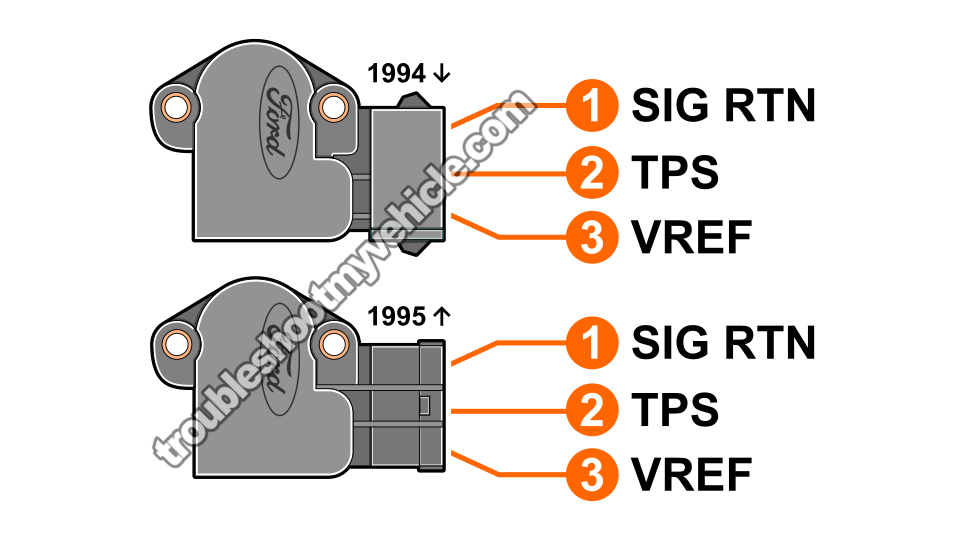

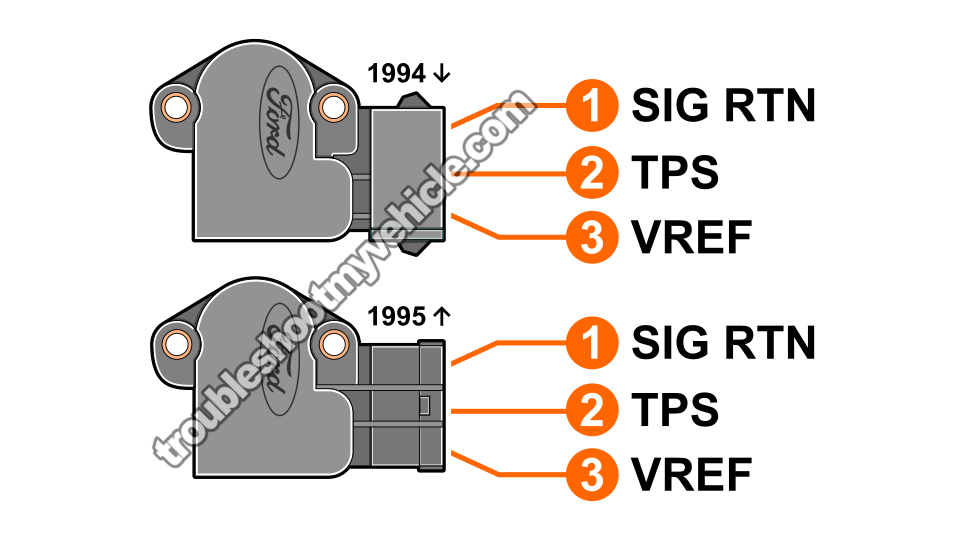

We'll be testing the gray with white stripe (GRY/WHT) wire, which connects to terminal 2 of the TPS connector (see the illustration above).

NOTE: The throttle position sensor must remain connected to its electrical connector to be able to test the TP signal. For this reason you'll need to use a back probe or a wire piercing probe to access the signals voltage inside the cable. This is the tool I use and you can buy it here: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link)..

NOTE: You'll notice in the illustration I'm using in this tutorial that there are two different types of TP sensors. The difference being that starting in the 1995 model year the connector changed with the introduction of the OBD II system. This tutorial covers both types of TP sensors.

These are the test steps:

- 1

Place your multimeter in Volts DC mode.

- 2

Connect the red multimeter test lead to the GRY/WHT wire of the TP sensor harness connector.

The GRY/WHT wire is the one that delivers the TPS signal to the fuel injection computer. - 3

Ground the black multimeter test lead directly on the battery negative (-) post.

- 4

Turn the key on but don't crank or start the engine. This will power up the TPS.

- 5

Manually rotate the throttle as you observe the voltage reading on your multimeter.

NOTE: You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 6

The multimeter should show an increasing voltage as you (or your helper) open up the throttle.

- 7

Slowly close the throttle plate as you observe the multimeter.

- 8

The multimeter should show a decreasing voltage as you begin to close the throttle.

- 9

Using a screwdriver's handle, gently tap the TP sensor as you open and close the throttle and observer the multimeter.

The purpose (of tapping the TP sensor with the screwdriver's handle) is to see if the TP sensor shows gap's in the voltage signal. Why? Because a good TP sensor will show a continuous increasing or decreasing voltage signal even while getting tapped by the screw-driver's handle.

Let's take a look at your test results:

CASE 1: The TP signal voltage increased/decreased as you opened/closed the throttle plate. This is the correct test result and lets you know that the TPS is working correctly. The TPS itself is not the cause behind the problem on your 3.8L Ford Taurus (Mercury Sable).

CASE 2: The TP signal voltage glitched out as you opened/closed the throttle plate. This test result lets you know that the throttle position sensor is defective.

When you're ready to replace the TP sensor, this is the one I recommend. It's affordable, comes from a well-known aftermarket brand, and will take care of the issue:

- Standard Motor Products TH63 Throttle Position Sensor (Amazon affiliate link).

CASE 3: The TPS voltage signal stayed stuck at one value when you opened/closed the throttle plate. This test result generally tells you that the TP sensor is defective.

To make sure that it is defective, the next step is to make sure the TPS has power and Ground. For this test go to: TEST 2: Making Sure The TPS Is Getting 5 Volts (VREF).

TEST 2: Making Sure The TPS Is Getting 5 Volts (VREF)

If you've reached this point, then TEST 1 confirms that the TPS signal voltage is stuck at one value, regardless of throttle plate angle.

Generally, this indicates that the TPS is bad —but before replacing it, we need to make sure it's getting the 5V VREF signal.

The wire that delivers this 5-Volt reference voltage to the sensor is the brown with white stripe (BRN/WHT) wire. This wire connects to the TPS terminal labeled with a number 3 in the illustration above.

This voltage is supplied by your Taurus or Sable's fuel injection computer and is only available when the key is in the RUN or START position. For our test, we'll check that this VREF voltage is present with the key in the RUN position but with the engine OFF.

NOTE: We'll be checking for this voltage at the female terminal of the connector. There's a good chance your multimeter test lead may be too thick to safely fit into the female terminal. Be careful when probing to avoid damaging the connector or terminal —otherwise, you'll need to replace the connector.

These are the test steps:

- 1

Disconnect the TP sensor from its 3-wire connector.

- 2

Connect the black multimeter test lead to the battery negative (-) post.

- 3

Turn the key to the RUN position (ON), but don't crank or start the engine.

- 4

Place your multimeter in Volts DC mode.

- 5

Gently probe the female terminal of the TP sensor connector that corresponds to the BRN/WHT wire with the red multimeter test lead.

The BRN/WHT wire is the VREF voltage supply wire. - 6

Your multimeter should register 4.5 to 5 Volts DC if the computer is supplying VREF voltage.

Let's interpret your test results:

CASE 1: The TP sensor is receiving 5 Volts. This test result confirms that the sensor is getting the VREF voltage it needs to function.

Our next and final test is to make sure the sensor is being supplied with the SIG RTN Ground from the fuel injection computer. For this test, go to: TEST 3: Making Sure The TPS Is Getting Ground (SIG RTN).

CASE 2: The TP sensor is not receiving 5 Volts. Double-check that you're testing the correct terminal —the one corresponding to the BRN/WHT wire on the connector— and repeat the test.

If you still don't see 5 Volts at the terminal, you can rule out the TP sensor as defective, since without this 5-Volt reference voltage, it can't function.

The most likely cause of this missing VREF voltage is an open or short-circuit issue in the BRN/WHT wire between the connector and the computer. Your next step is to find out why this voltage is missing and restore it to the circuit. Once this voltage is restored, the sensor will function again and the TPS trouble code will clear.

TEST 3: Making Sure The TPS Is Getting Ground (SIG RTN)

Up to this point, your first two TP sensor tests have confirmed the following:

- TEST 1: The TP signal voltage does not react when you open or close the throttle plate.

- TEST 2: The sensor is receiving VREF power.

For our final diagnostic test, we're going to make sure the throttle position sensor is getting its SIG RTN Ground.

This Ground is supplied by your Taurus or Sable's fuel injection computer and is only available when the key is in the RUN or START position. For our test, we'll check for its presence at the terminal that connects to the gray with red stripe (GRY/RED) wire, with the key in the RUN position but the engine OFF.

NOTE: Since the SIG RTN Ground is provided internally by the fuel injection computer, it's very important that you don't accidentally or intentionally connect this circuit to battery voltage —doing so will deep fry the computer. The multimeter voltage test outlined below is a safe way to check for the presence of this Ground in the circuit.

These are the test steps:

- 1

Disconnect the TP sensor from its 3-wire connector.

- 2

Connect the red multimeter test lead to the battery positive (+) post.

- 3

Turn the key to the RUN position (ON), but don't crank or start the engine.

- 4

Place your multimeter in Volts DC mode.

- 5

Gently probe the female terminal of the TP sensor connector that corresponds to the GRY/RED wire with the black multimeter test lead.

The GRY/RED wire is the SIG RTN Ground supply wire. - 6

Your multimeter should register 4.5 to 5 Volts DC if the computer is supplying VREF voltage.

Let's interpret your test results:

CASE 1: The TP sensor is receiving the SIG RTN Ground from the computer. This confirms that the TP sensor has the Ground it needs to produce a proper TP signal.

We can correctly conclude that the throttle position sensor is defective and needs to be replaced only if the following have been confirmed:

- TEST 1: The TP signal voltage output stays stuck at one value no matter how much you move the throttle.

- TEST 2: The sensor is receiving the 5V VREF voltage.

- TEST 3: The sensor is receiving the computer-supplied SIG RTN Ground.

When you're ready to replace the TP sensor, this is the one I recommend. It's from a well-known aftermarket brand (that's inexpensive), and will solve the issue:

- Standard Motor Products TH63 Throttle Position Sensor (Amazon affiliate link).

CASE 2: The TP sensor isn't receiving the SIG RTN Ground from the computer. Make sure you're testing the correct terminal —the one connected to the gray with red stripe wire on the connector— and repeat the test.

If the terminal still doesn't show the presence of the SIG RTN Ground, then we can conclude that the TP sensor itself is OK and not the cause of the TPS diagnostic trouble code, since without this Ground, it simply can't function.

The most likely cause of this missing SIG RTN Ground is an open or short-circuit in the GRY/RED wire between the TP sensor connector and the computer. You'll need to focus your troubleshooting efforts on finding out why this Ground is missing and restore it to the circuit. Once the TP sensor's Ground supply is restored, it'll function properly again and the code will clear.

TPS Trouble Code Won't Go Away

I've seen a few cases where the fuel injection computer accuses the TPS of malfunctioning by setting a TPS trouble code yet the sensor is functioning correctly.

In these cases it's usually some other mechanical issue that's fooling the fuel injection computer into thinking the TPS is defective. So, if you're experiencing a similar situation, I think the following suggestions may help you to save sometime, frustration, and money:

- Check that the TP sensor's wiring harness connector for damage.

- It's a common problem for the locking tab, of the connector, to break and cause a false contact condition as you drive the vehicle on the road.

- Check that the throttle plate idle stop screw isn't misadjusted.

- What I've seen quite a bit, is that the idle stop screw has been adjusted to increase the engine's idle RPM to mask a rough idle condition. But doing this usually causes the computer to set a TPS trouble code.

- Check the continuity of the wires between the fuel injection and the throttle position sensor.

- The idea behind this test is to make sure that there isn't an open-circuit in the wiring between the TPS and the fuel injection computer.

- Check that the computer isn't defective. This can seem like quite a challenge but it's possible. This is how you can conclude that you have a defective fuel injection computer on your hands:

- Eliminate the throttle position sensor as defective first.

- Make sure that the wiring between the TPS and the computer has continuity. In other words there aren't any short-circuits or open-circuits in the wiring between these two.

- Confirm that the fuel injection computer's Ground wires are actually feeding it Ground. The best way to do this is to do a voltage drop test on each fuel injection computer's Ground wires.

- Confirm that the fuel injection computer has power in each of its power wires.

- After eliminating the TPS itself, after verifying the continuity of the TP sensors 3 wires (between its connector and the fuel injection computer), after verifying that the fuel injection has good Ground and power; then and only then can you conclude that there might be a problem with the computer internally.

More 3.8L V6 Ford Taurus Diagnostic Tutorials

You can find a complete list of diagnostic tutorials for the 3.8L V6 Ford Taurus and Mercury Sable in this index:

Here's a sample of the tutorials you'll find for the 3.8L Ford Taurus (Mercury Sable):

- How To Test The MAF Sensor (1991-1995 3.8L V6 Ford Taurus, Mercury Sable).

- How To Test The Fuel Pump (1990-1995 3.8L V6 Ford Taurus, Mercury Sable).

- How To Test The Engine Compression (1990-1995 3.8L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1990-1995 3.8L V6 Ford Taurus, Mercury Sable).

If this info saved the day, buy me a beer!