The fuel pump is going to fail sooner or later on your 4.2L V6 equipped E150 or E250. In this tutorial, I'll explain how to test the fuel pump using a fuel pressure gauge.

With your test results, you'll quickly find out if the fuel pump has failed and is causing either an engine performance problem or an engine no-start problem.

I'm also gonna explain how to use starting fluid to find out if a 'lack of fuel condition' is causing the engine to not start.

Contents of this tutorial:

- Common Symptoms Of A Bad Fuel Pump.

- Where To Buy A Fuel Pressure Test Gauge.

- Safety Precautions To Take When Testing The Fuel Pump Pressure.

- Fuel Pressure Specifications.

- TEST 1: Testing The Fuel Pressure With A Fuel Pressure Test Gauge.

- TEST 2: Using Starting Fluid To Diagnose A No-Start Condition.

- Fuel Pump Inertia Switch Check.

- More 4.2L Ford E150 And E250 Test Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 4.2L V6 Ford E150: 1997, 1998, 1999, 2000.

- 4.2L V6 Ford E250: 1997, 1998, 1999, 2000.

2001-2003 FUEL PUMP PRESSURE TEST: If you need to see the fuel pressure test for the 2001-2003 4.2L V6 Ford E150 (E250), go here:

F-SERIES PICKUPS: The fuel pump diagnostic tutorial for the 1997-2000 4.2L V6 Ford F150/F250 can be found here:

- How To Test The Fuel Pump (1997-2003 4.2L V6 Ford F150, F250) (at: easyautodiagnostics.com).

1997-1999 FUEL PUMP CIRCUIT WIRING DIAGRAM:

Common Symptoms Of A Bad Fuel Pump

Typically, a fuel pump is going to fail in one of two ways:

- Low pressure issue: The fuel pump works just enough to send fuel to start the engine but not enough to keep it running optimally under load.

- No pressure issue: In this scenario, the fuel pump assembly stops working and doesn't send any fuel to the engine causing it not to start.

Although the following is not the most exhaustive list of symptoms of a bad or failing fuel pump, these are the most common ones you're going to see:

- Engine No Start: The engine cranks but does not start.

- Stalling After Start: The engine starts but stalls after a few seconds.

- Stalling On Acceleration: The engine starts but as soon as you step on the accelerator pedal, the engine stalls.

- No Power Under Load: Lack of power while driving the vehicle.

- Backfiring: Explosions (loud popping sounds) can be heard coming from the intake manifold when you step on the accelerator while the engine is under load.

- Check Engine Light : The check engine light is on, and lean air-fuel mixture trouble codes are stored in the fuel injection computer's memory.

Before we go to the next section, I just want to highlight that other components can fail and cause similar issues, just like a bad fuel pump. So, it's really important to test the fuel pump's pressure with a gauge before you decide to change it, and that's what I'll show you how to do.

Where To Buy A Fuel Pressure Test Gauge

You can buy a fuel pressure test gauge just about anywhere and is one of the most important tools any serious DIY'er should have in his/her tool box.

All of the following fuel pressure test gauge kits will help test your 4.2L Ford E150 or E250's fuel pump:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Safety Precautions To Take When Testing The Fuel Pump Pressure

Before you start your tests, remember to play it safe to avoid any accidents or surprises. Here are a couple of important precautions to take:

- Work With A Cold Engine: Work with a cold engine when testing the fuel pump's fuel pressure or using starting fluid to reduce the risk of burns and injuries. Additionally, working with a cold engine reduces the risk of accidental ignition of fuel vapors.

- Avoid Flames And Sparks: When working with fuel-related components, it's crucial to avoid any open flames, sparks, or sources of ignition. This includes smoking, using electrical equipment that could produce sparks, or working near any other potential ignition sources. Gasoline and starting fluid vapors are highly flammable and can ignite easily, leading to fires or explosions.

- Wear Protective Gear: Wear appropriate protective gear to protect yourself from potential fuel spills or accidents. This may include safety glasses to protect your eyes from fuel splashes, gloves to prevent skin contact with fuel or chemicals, and appropriate clothing to minimize exposure to fuel vapors.

- Have a Fire Extinguisher Nearby: Have a fire extinguisher nearby in case of an emergency. Make sure the fire extinguisher is rated for use with flammable liquids and that you know how to use it effectively.

- Follow Fuel Pressure Gauge Manufacturer Instructions: When using a fuel pressure gauge to test the fuel pump's fuel pressure, it's important to follow the manufacturer's instructions carefully. This ensures that the gauge is connected properly and that the testing procedure is conducted safely. Incorrect use of a fuel pressure gauge can lead to inaccurate readings.

By following these safety measures, you can minimize the risk of accidents and perform the pressure check effectively and safely.

Fuel Pressure Specifications

The following fuel pressure specifications apply to the 1997-2000 4.2L V6 Ford E150 and E250:

| Fuel Pressure With The Key On Engine Off |

|---|

| 35-45 PSI. |

| Fuel Pressure With The Key On Engine Running |

|---|

| 28-45 PSI. |

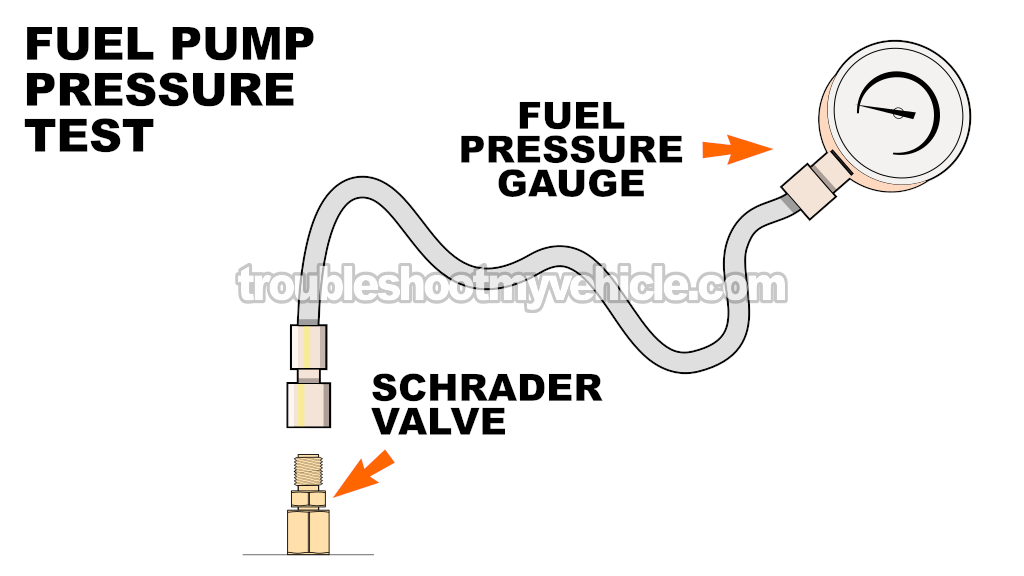

TEST 1: Testing The Fuel Pressure With A Fuel Pressure Test Gauge

Using a fuel pressure test gauge to check the fuel pump pressure is the most accurate way to check the fuel pump's performance.

The 1997-2000 4.2L V6 Ford engines feature a fuel pressure test port on the fuel rail, making it easy to connect a test gauge and check the pump's pressure.

This fuel pressure test port, often called the Schrader valve, is located on the driver's side fuel injector rail (which is somewhat hidden by the intake manifold plenum).

Since the engine has two fuel injector rails (for bank 1 and bank 2), the one with the Schrader valve is the one where the fuel supply and return lines are connected.

IMPORTANT: If you haven't already done so, check the fuel pump inertia switch first. See: Fuel Pump Inertia Switch Check.

NOTE: You'll need a fuel pressure tester that can connect to the Schrader valve. If you don't have one, take a loot at my recommendations here: Where To Buy A Fuel Pressure Test Gauge.

These are the test steps:

- 1

Locate the Schrader valve on the fuel injector rail crossover line (see photos above).

- 2

Remove the dust cap from the Schrader valve and place a shop towel under the general area of the Schrader valve.

NOTE: The shop towel's job is to absorb and fuel that may leak when performing step 3. - 3

Connect your fuel pressure tester to the Schrader valve.

- 4

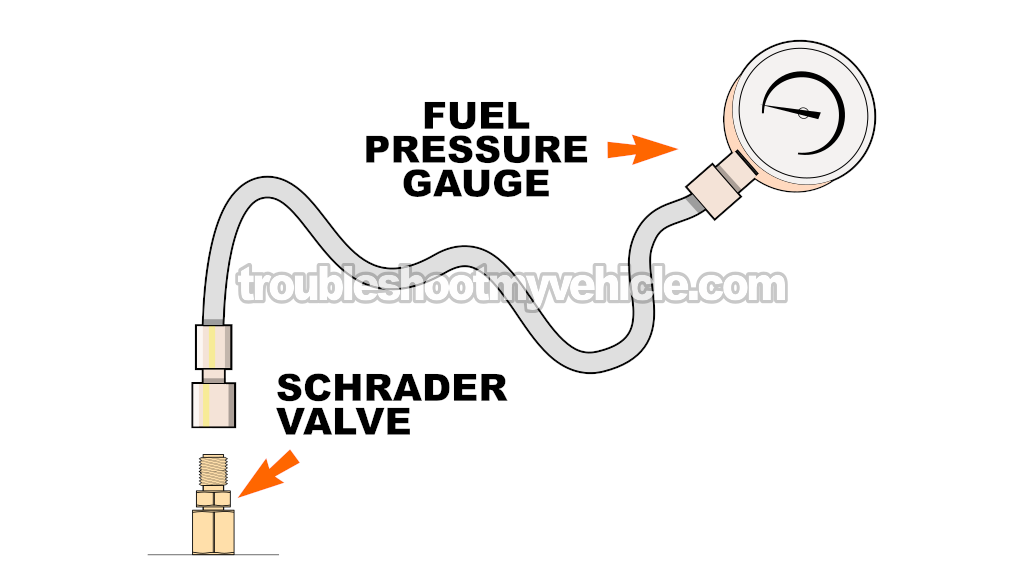

Have your helper crank the engine while you observe the needle on the fuel pressure tester gauge.

- 5

Your fuel pressure gauge should register:

Engine Does NOT Start: 35-45 PSI.

Engine Starts: 28-45 PSI.

Let's examine your test results:

CASE 1: The fuel pressure is within the indicated specification. This is the correct test result.

This test result confirms that the fuel pump in your Ford E150/E250 van is OK (functioning correctly).

CASE 2: You got 0 PSI fuel pressure. This test result lets you know that the fuel pump is defective and is causing the engine to not start.

Before you replace a fuel pump make sure that the fuel pump relay and fuel pump fuse are supplying power to the fuel pump when the engine is being cranked.

If battery power is available to the fuel pump, when cranking the engine, then you can confidently conclude that the fuel pump is defective and that it needs to be replaced.

CASE 3: The fuel pressure was below the indicated fuel pressure specification. This test result lets you know that even though the fuel pump is supplying some fuel it's not supplying enough to have the engine run optimally.

This is an indication that the fuel pump is failing and needs to be replaced.

TEST 2: Using Starting Fluid To Diagnose A No-Start Condition

Performing a starting fluid test is an easy and quick way to figure out if a lack of fuel is causing the engine not to start.

While I do want to mention that this test isn't as accurate as a fuel pump pressure test for diagnosing a bad fuel pump, it's one of my go-to methods at the beginning of any engine no-start diagnostic.

One of the reasons I love this test is that it helps me quickly narrow down the issue, and then I follow up with a fuel pressure gauge test.

IMPORTANT: To achieve the most accurate result from your starting fluid test, make sure all 6 cylinders are getting spark. If you haven't checked for spark yet, do so before proceeding with the starting fluid test.

CAUTION: As a safety precaution, you should never spray starting fluid into the throttle body while the engine is cranking. Instead, you should first spray starting fluid into the throttle body and then crank the engine.

These are the test steps:

- 1

Remove the intake air duct from the throttle body. You don't have to completely remove it, since you'll have to reconnect it in step 2.

- 2

Spray starting fluid down the bore of the throttle body.

After spraying a good squirt of starting fluid, quickly reconnect the air duct to the throttle body (you don't have to tighten the hose clamp). - 3

Have your helper crank the engine once the intake air duct is back on the throttle body.

- 4

You'll get one of two results with this test:

1.) The engine will start momentarily and after a few seconds will die.

2.) The engine will only crank but not start at all.

OK, let's find out what your results mean:

CASE 1: The engine did not start, not even a few seconds. This test result tells you that a lack of fuel from the fuel pump IS NOT causing the engine's no-start problem.

I want to point out that this conclusion is true only if all spark plug wires are sparking.

CASE 2: The engine started but died after a few seconds. This test result tells you that the engine's no-start problem is caused by a lack of fuel.

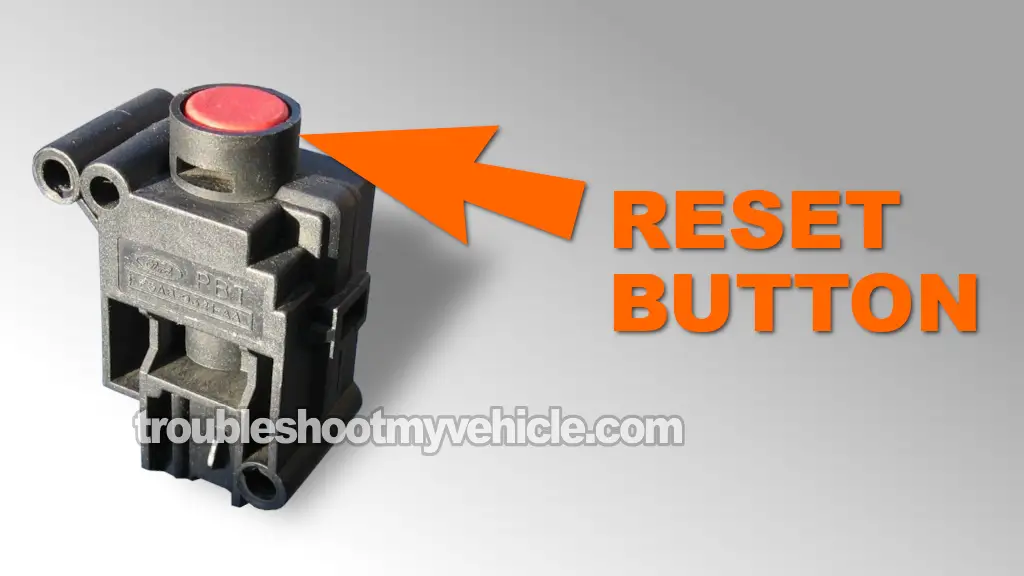

Fuel Pump Inertia Switch Check

Your Ford E-150/E250 van comes equipped with a fuel pump inertia switch designed to shut off the fuel pump in case of a collision (it's located behind the right side kick panel).

Whenever the fuel pump inertia switch detects a sudden and forceful stop or impact, such as in a car crash, the switch cuts power or Ground to the fuel pump, which stops the flow of gasoline to the engine.

Cutting the flow of fuel to the engine (in case of crash) reduces the risk of fuel leaking and igniting if parts of the fuel system are damaged during the accident.

While this switch is primarily meant to activate during a pretty significant impact, such as in a car crash, it can sometimes be triggered by lighter bumps.

Since a light bump can trigger it, it's important to always check and reset the inertia switch as part of any fuel pump testing process.

To reset it, simply press down firmly on the button at the top of the switch until it clicks into place.

More 4.2L Ford E150 And E250 Test Tutorials

If this tutorial was helpful, be sure and take a look at all of the 4.2L V6 E150 and E250 diagnostic tutorials in this index:

Here's a sample of the tutorials you'll find there:

- How To Test The Throttle Position Sensor (1997-2000 4.2L V6 Ford E150, E250).

- How To Test Engine Compression (1997-2003 4.2L V6 Ford E150, E250).

- How To Test The CKP Sensor With A Multimeter (1997-2003 4.2L V6 Ford E150, E250).

- How To Test For A Blown Head Gasket (1997-2003 4.2L V6 Ford E150, E250).

If this info saved the day, buy me a beer!