One of the most common problems on the GM 3.1L and 3.4L V6 engines is coolant leaking from the intake manifold gaskets. This problem has been a gold mine for GM and the auto repair industry. Although GM has been aware of this problem ‘since man learned to walk upright and harnessed the power of fire’, they haven't done much to correct it (other than to deflect blame onto the owner of the vehicle for supposedly using the wrong type of coolant).

So, you might be wondering, is there a way to prevent this from happening? The answer is both a yes and no. Having worked on cars as a professional automotive tech for about 20 years and having repaired this condition many many times, I can tell you that you can do certain things to avoid a repeat of this problem. In this article I'll offer you several suggestions on what you can do to mitigate this problem.

ES ![]() You can find this tutorial in Spanish here: El Defecto De Los Empaques Del Múltiple De Admisión (3.1L, 3.4L GM) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: El Defecto De Los Empaques Del Múltiple De Admisión (3.1L, 3.4L GM) (at: autotecnico-online.com).

What Causes The Intake Manifold Gaskets To Leak Coolant?

In a nutshell, it's because the intake manifold gaskets are made out of a composite material (the technical name for plastic).

Compounding the problem is that the metal that the intake manifold gaskets are sandwiched between, expands when it heats up and contracts when it cools down (remember, the intake manifold gaskets are sandwiched between the intake manifold and the cylinder head -which are made up of aluminum metal).

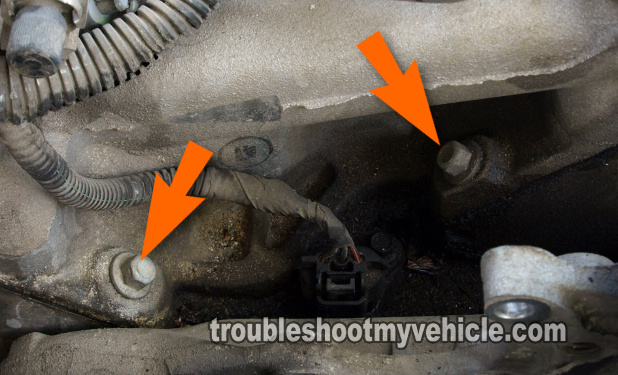

Over time and thousands of miles, this action of expansion and contraction of the surfaces that the intake gaskets are sandwiched between (plus the rushing/moving coolant) starts to eat away and/or tear the intake gaskets at their coolant ports. This eventually results in gaskets that look like the one in the photos I'm using in this article.

Before anyone gets their ‘knickers in a twist’ I want to emphasize that I'm expressing an opinion, namely mine -that the geniuses at GM probably figured out the exact formula to make these plastic gaskets last just long enough to outlive the typical new car warranty. Once out of warranty, well you know that you're the one that's gonna' have to pay for it.

If you do own a vehicle equipped with a 3.1L or 3.4L engine, chances are that you have already experienced this ‘intake gaskets leaking coolant’ condition (and have repaired it), or you're experiencing it right now or will be soon enough. Is there something that can be done to avoid a repeat of this particular problem? The answer is yes and it involves using an updated type of intake manifold gasket made by Felpro and tightening the intake manifold bolts with a torque wrench to specification.

Updated Intake Manifold Gaskets

Whether you replace the leaking intake manifold gaskets yourself or you're having it done at your local automotive repair shop, you need to use or ask for the updated intake manifold gaskets made by Felpro.

Why? Because the old plastic type gaskets are still being produced and sold. Not too mention that there's a price difference between both.

Now, in case you're wondering what the heck is the difference between them, the difference between the standard and the updated gaskets is huge.

The updated gaskets have a metal shim type core with rubber gaskets lining the ports as opposed to an all plastic core.

The updated intake manifold gaskets are usually called the ‘premium’ intake manifold gaskets and the old plastic type are known as the ‘standard’ intake manifold gaskets.

Using the updated metal shim type intake manifold gaskets is just only one part of the equation. The other factor, that also determines whether the new (or even the standard intake manifold gaskets) are not going to leak for a long time is torquing the intake manifold bolts to their proper torque specification.

Tightening The Lower Intake Manifold Bolts With A Torque Wrench

To make sure your intake gasket replacement doesn't come back with a coolant leak in the near or long term, there's another very important consideration to keep in mind and it's that you need to torque the intake manifold bolts with a torque wrench.

GM skimped on both the amount and size of the bolts used to keep the intake manifold bolted to the cylinder heads. What I mean is that these are small diameter bolts that have a very small tightening torque specification.

This can lead to one of two things, if you don't use a torque wrench to tighten them:

- Loose bolts that will contribute to vacuum and coolant leaks from the intake gaskets.

- Over-tightened bolts that will crush the intake gaskets and eventually destroy their sealing ability or stripped bolt threads in the bolt hole (in the cylinder head).

What complicates this job, for the Do-It-Yourself'er who's not a professional mechanic, is that this torque wrench has to be able to torque in inch/pounds and finding one of these torque wrenches usually means having to order it via mail.

Where To Buy The Updated Gaskets And Save

You can buy the updated metal shim type intake manifold gaskets for a whole lot cheaper than somewhere local.

The following links will help you comparison shop for the updated gaskets (that also include the valve cover gaskets you need to remove in order to get to the intake gaskets):

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above updated intake manifold gasket sets fit your particular vehicle? Don't worry, once you get to the site, they'll make sure it fits by asking you the specifics of your particular 3.1L/3.4L GM vehicle and checking. If they don't fit, they'll find you the right updated intake manifold set.

In Conclusion

So, in conclusion, I know it sucks that you're having this particular problem with your 3.1L or 3.4L GM vehicle but, you can prevent a repeat of the problem by doing two very important things: 1.) Use the updated intake manifold gaskets and 2.) torque the intake manifold bolts with a torque wrench to specification.

If this info saved the day, buy me a beer!