TEST 2: Verifying Throttle Position Sensor Has Power

One of the things that can stop the TPS from creating a voltage signal is if the sensor is not getting power.

So, if your TPS did not pass TEST 1, then before we condemn the TPS as bad, we need to check that the gray with red stripe (GRY/RED) wire of the TPS connector is feeding the sensor with 5 Volts DC.

We'll do a simple multimeter voltage test to confirm that these 5 Volts are indeed present.

OK, these are the test steps:

- 1

Place your multimeter's dial in Volts DC mode and turn the key on but don't start the engine.

This will power up the TP sensor's connector. - 2

Disconnect the TPS from its electrical connector.

- 3

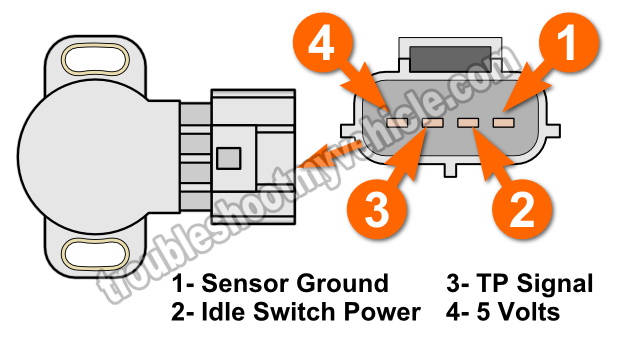

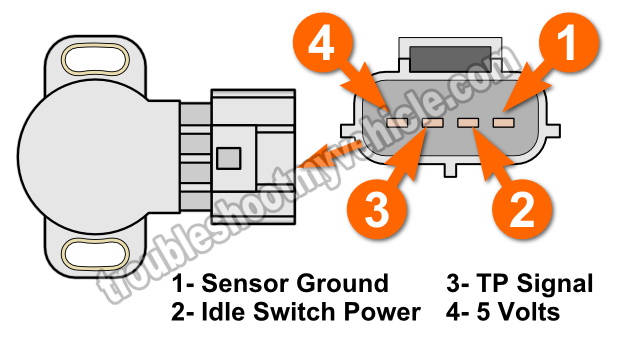

Probe the GRY/RED wire of the TPS connector with the red multimeter test lead. The GRY/RED wire connects to TPS pin #4 in the illustration above.

IMPORTANT Use a back probe or a wire piercing probe instead of probing the front of the TPS electrical connector. - 4

Connect the black multimeter test lead to the negative (-) battery terminal.

- 5

When you've set up the test, have a helper turn the key to the ON position but don't crank or start the engine.

- 6

Your multimeter should display 4.5 to 5 Volts on its screen if the GRY/RED wire has power.

Let's take a look at your test results:

CASE 1: The GRY/RED wire, of the TPS connector, has 4.5 to 5 Volts. So far so good since this tells you that the throttle position sensor (TPS) is getting power from the fuel injection computer.

The next and last test, is to make sure that the throttle position sensor is getting Ground (from the PCM too). For this test, go to: TEST 3: Verifying Throttle Position Sensor Has Ground.

CASE 2: The GRY/RED wire, of the TPS connector, DOES NOT have 4.5 to 5 Volts. Double check all of your connections and repeat the test.

If your multimeter still doesn't register the 4.5 to 5 Volts DC, then this test result tells you that the TPS itself is not at fault (and thus causing the TPS trouble code). Without power, the TPS can't create a throttle angle voltage signal. Although beyond the scope of this tutorial, your next step is to diagnose and restore this missing power.

TEST 3: Verifying Throttle Position Sensor Has Ground

So far, your diagnostic tests have confirmed several things:

- You have a TPS trouble code lighting up the check engine light on your Sidekick.

- The TPS's throttle plate position voltage signal IS NOT increasing/decreasing as you manually open/close the throttle plate (TEST 1).

- The TPS is getting power on the GRY/RED wire of its electrical connector (TEST 2).

The next step is to see if the GRY/YEL wire of the TPS connector is feeding Ground to the TPS. We'll check for this Ground by doing a multimeter voltage test.

IMPORTANT: Ground is provided directly by the fuel injection computer. Be careful and don't intentionally or accidentally short this wire (circuit) to battery power or you will fry the fuel injection computer.

OK, here are the test steps:

- 1

Set your multimeter to Volts DC mode.

- 2

Disconnect the TPS from its electrical connector.

- 3

Probe the GRY/YEL wire of the TPS connector. The GRY/YEL wire connects to TPS pin #1 (see illustration above).

NOTE: Be careful not to damage the terminal if you probe it on the front of the connector. If possible, you should use a back probe or a wire-piercing probe to check this circuit. - 4

Connect the red multimeter test lead to the battery positive (+) terminal.

- 5

Turn the key to its ON position but don't start the engine. This will power up the fuel injection computer.

- 6

Your multimeter will display 10 to 12 Volts if terminal #1 is feeding the TPS with Ground.

Let's see what your test result means:

CASE 1: The GRY/YEL wire is feeding the TPS ground. This is the correct and expected test result. Now, if you arrived to this test conclustion by starting out with TEST 1, then you can conclude that the TP sensor is bad and needs to be replaced.

To explain why (you need to replace the TPS): Up to this point, you have verified:

- The TP sensor's voltage signal DOES NOT increase/decrease when you manually opened/closed the throttle plate.

- The TP sensor is being fed 5 Volts DC.

- The TP sensor is being fed Ground.

So, taking all of these test results together you can conclude the TPS is bad and needs to be replaced.

CASE 2: The GRY/YEL wire IS NOT feeding the TPS ground. Check your test connections once more and repeat the test. If your multimeter still does not register 12 Volts, then you can conclude that:

- The TPS itself is NOT bad.

- There's an open in the wire between the TP sensor harness connector and the fuel injection computer's harness connector.

- The fuel injection computer has an internal problem (although this is extremely rare).

Although testing these two conditions are beyond the scope of this article, you have now eliminated the throttle position sensor (TPS) on your 1.6L Sidekick (1.6L Tracker) as being the cause of the problem and/or the TP sensor diagnostic trouble code (DTC) lighting up the check engine light (CEL).

How To Adjust The 1.6L Sidekick TPS

The Suzuki manual calls for the TPS to be adjusted when removed. So in this section I'll explain the adjustment procedure below:

- Disconnect the negative battery terminal from the battery.

- Loosen the throttle position sensor screws.

- Place a 0.026" (0.65mm) feeler gauge between the throttle lever and throttle lever stop screw.

- Place your multimeter in Ohms mode.

- Check the resistance between TPS pin #1 and pin #2. Continuity must exist between these two pins while the feeler gauge is inserted between the throttle lever and the throttle lever stop screw.

- If continuity does not exist between pin #1 and #2, rotate the TPS assembly till it does and then tighten the TPS screws.

- After tightening the TPS screws, re-check that continuity still exists between pin #1 and #2 (with the feeler gauge still inserted).

If this info saved the day, buy me a beer!