STARTER TEST 2: Applying 12 V To The S Terminal

In TEST 1, you confirmed that the starter motor is getting the activation signal from the ignition switch and thus, you have indirectly confirmed that the ignition switch (and all of the circuits in-between it and the starter motor) are OK.

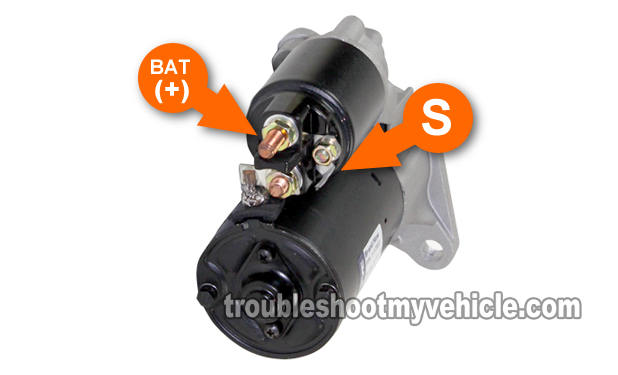

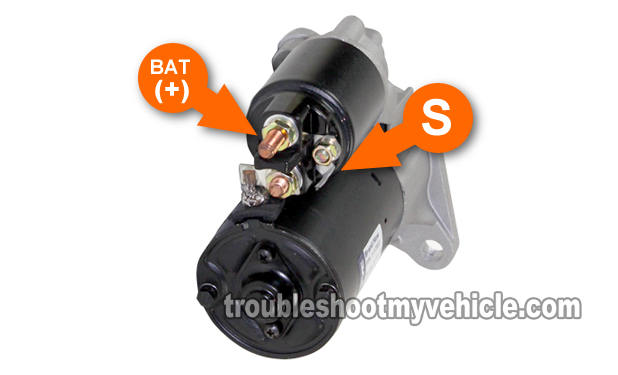

The next step is to apply 12 Volts to the S terminal of the starter motor solenoid, using a jumper wire to see if the starter will activate or not.

This is a very simple test, but you do have to take two important precautions:

PRECAUTION 1: The ignition must be in its OFF position, or better yet remove the key from the ignition switch. This will prevent the engine from starting in case the starter motor is OK.

PRECAUTION 2: If your vehicle has a standard transmission, make sure that it's out of gear and in neutral, and the parking brake is activated/on.

PRECAUTION 3: There's a good chance that the starter motor is OK and when you apply these 12 Volts with the jumper wire, the engine may start so be careful, take all necessary safety precautions and think safety as you do this test.

OK, this is what you'll need to do:

- 1

Disconnect the wire that attaches to the S terminal of the starter motor solenoid.

- 2

Using a jumper wire that's long enough, apply 12 Volts to the S terminal of the starter motor solenoid.

- 3

As you apply these 12 Volts (to the S terminal of the starter solenoid), you'll get one of two results:

1.) The starter will activate and will turn over the engine

2.)The starter motor won't do a thing.

Let's take a look at what your test results mean:

CASE 1: The starter motor cranked the engine. This means that the starter motor is good and that you have an electrical issue keeping the starter motor from cranking the engine.

CASE 2: The starter motor DID NOT crank the engine. This usually means that your starter motor is bad and needs to be rebuilt or replaced.

I suggest one more test and this is to test the battery cable (that attaches to the starter motor solenoid) for corrosion. This can be accomplished very easily with a voltage drop test. Go to TEST 3: Voltage Drop Testing The Battery Circuit.

STARTER TEST 3: Voltage Drop Testing The Battery Circuit

Corrosion on your battery's positive cable can keep the starter motor from cranking your 2.0L or 2.4L 4 cylinder equipped Chrysler, even if they look corrosion-free or you clean them.

So, what I have always done, is to voltage drop test the battery positive cable (that attaches to the starter motor solenoid) to make sure that the starter motor is getting all of the battery's available power.

A voltage drop test is an easy and fast test that will give you an accurate result that can be interpreted as: ‘Yes, the starter motor is getting all of the battery's available power’ or ‘No, it's not getting all of the battery's available power’.

- 1

Place your multimeter's dial on Volts DC.

- 2

With the red multimeter test lead, probe the large stud, on the starter motor solenoid, that has the battery positive cable attached.

- 3

With the black multimeter test lead, probe a clean spot right in the center of the battery positive post. Do not probe the terminal on the cable, but the center of the battery positive post.

- 4

When ready, have your assistant crank the car as you keep your eyes on the multimeter.

Now, the starter motor isn't going to crank the engine, but it's necessary to turn the key to the Start (crank) Position for the voltage drop test to work. - 5

Your multimeter will give one of two possible results, and they are:

1.) The multimeter will register a 0 voltage which indicates no voltage drop.

2.) The multimeter will register a voltage, usually 5 Volts or more and this test results means that there is a voltage drop in the circuit and this is not good.

OK, now that the testing part is done, let's take a look at what your results mean:

CASE 1: Your multimeter result confirms NO voltage drop (which is 0.5 Volts or less). This means that the battery positive cable is corrosion-free and that it is transmitting all of the battery's available power to the starter motor. Replace the starter motor.

What if you're reading this article because you have already replaced the starter motor and the engine still doesn't crank? Well, I suggest two more tests:

1.) Confirm that the engine is not locked up due to a thrown rod or a locked up AC compressor. You can easily do this by turning the engine manually (using a 1/2 ratchet and the appropriate socket).

2.) Test the starter motor that you just got from the auto parts store -it could be bad. You can do this by bench testing the starter motor. The step-by-step instructions here: How To Bench Test A Starter Motor (Step By Step) (at: easyautodiagnostics.com).

CASE 2: Your multimeter indicated a voltage drop. This means that your multimeter registered a voltage reading (usually 5 Volts DC or more), and this voltage reading means that the starter motor isn't getting all of the battery's available power. This will keep the starter motor from cranking the engine.

The solution is simple, just thoroughly clean both ends of the battery positive cable and both battery posts. The positive battery cable end that attaches to the starter motor solenoid can be cleaned with a piece of sand paper.

Once you're done and have reconnected both ends of the cable, re-test or simply crank up the car. More than likely it'll now crank and start.