In this tutorial, I'm going to help you diagnose and test the manifold absolute pressure sensor, commonly known as the MAP sensor.

The MAP sensor is a pretty easy component to test, and it can be tested with a multimeter. You don't need a scan tool to test it.

In this tutorial, I'm going to show you the three tests you need to perform to find out if it's good or bad. I'm also going to show you where you can buy it and save a few bucks on its purchase.

Contents of this tutorial:

ES ![]() You can find this tutorial in Spanish here: Probando El Sensor MAP (1996-2000 2.4L Dodge, Plymouth Minivan) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Probando El Sensor MAP (1996-2000 2.4L Dodge, Plymouth Minivan) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles (since they use the exact same MAP sensor):

- 2.4L Dodge Caravan: 1996, 1997, 1998, 1999, 2000.

- 2.4L Plymouth Voyager: 1996, 1997, 1998, 1999, 2000.

Symptoms Of A Bad MAP Sensor

The fuel injection system on your 2.4L Dodge Caravan (Plymouth Voyager) is a speed density type of system.

What this means in plain English, is that the fuel injection computer needs to know three basic things to be able to inject the correct amount of fuel into the engine.

These three things are: air intake temperature, engine RPM, and engine load.

The sensor that is tasked with reporting the engine to load, to the fuel injection computer, is the manifold absolute pressure sensor.

Since the MAP sensor is monitored by the computer the entire time the engine is running, when it fails oh, the computer is going to set a MAP sensor diagnostic trouble code. You'll see one of the following codes lighting up the check engine light on your minivans instrument cluster:

- P0106: MAP System Performance.

- P0107: MAP Sensor Circuit Low Voltage.

- P0108: MAP Sensor Circuit High Voltage.

Besides the diagnostic trouble codes, your Chrysler/Dodge 2.4L equipped minivan is not gonna' run right. You'll experience one or several of the following symptoms:

- Rough idle.

- Black smoke coming out of the tail-pipe.

- Engine stalls under load.

- Engine dies as soon as it starts.

- Lack of power when you accelerate the vehicle down the road.

MAP sensors go bad all of the time but sometimes some other condition (affecting engine performance) fools the PCM (Powertrain Control Module = Fuel Injection Computer) into thinking that the MAP sensor is has failed.

To be absolutely sure the MAP sensor is bad or not (without replacing to find out), you need to bench test it and the MAP sensor test that I'm gonna' show you is a MAP sensor bench test.

If after doing the MAP sensor test and the MAP sensor is good, then take a look at the section: MAP Sensor Code Won't Go Away.

How The MAP Sensor Works

The fuel system in your 2.4L equipped Chrysler minivan is a ‘speed density’ type. Which, among other things, means it doesn't use a mass air flow (MAF) sensor to measure the amount of air the engine is breathing.

To be a bit more specific, the PCM uses the MAP sensor to measure the amount of vacuum inside the engine, the crank sensor to know the engine's RPMs, and the IAT sensor to measure the intake air temperature to calculate the amount of air entering the engine.

With this info, the fuel injection computer can calculate the approximate amount of air entering the engine, adjust fuel injector pulse width, adjust ignition timing, etc.

This is what happens when you turn the key and start the engine:

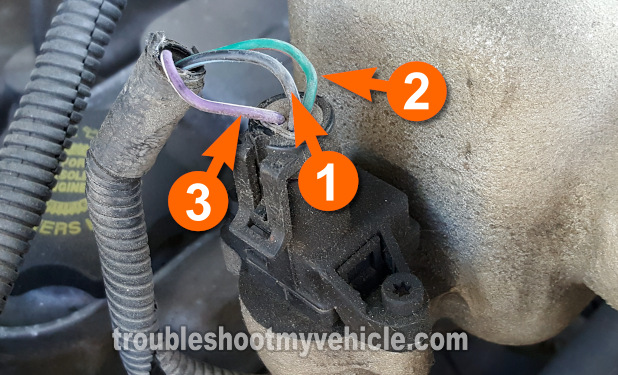

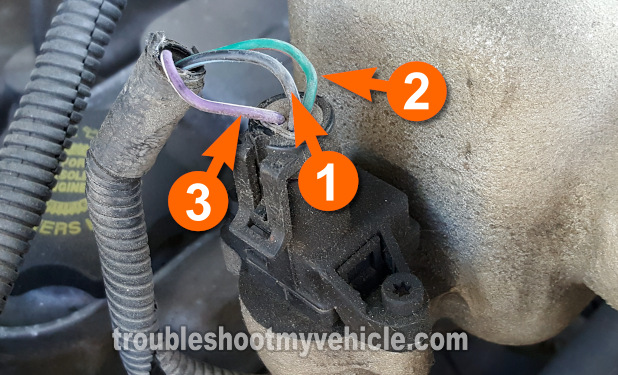

- The PCM feeds 5 Volts to the MAP sensor thru' the wire labeled with the number 3.

- Ground is provided, by the PCM too, thru' the wire labeled with the number 1.

- Once the MAP sensor gets power and Ground, it now starts to measure the amount of vacuum the engine is producing and shoots the info to the PCM thru' the wire labeled with the number 2.

The MAP sensor plays an important role in the performance and efficient operation of the engine in your 2.4L equipped Chrysler or Dodge minivan. With this info under our belts, let's get testing.

Where To Buy The MAP Sensor And Save

If you find that the MAP sensor is bad, check out following links and comparison shop. I think they'll help you save a few bucks on its purchase.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above MAP sensor fits your particular 2.4L Dodge Caravan or 2.4L Plymouth Voyager? Don't worry, once you get to the site, they'll make sure it fits by asking you the particulars of your vehicle. If it doesn't fit, they'll find you the right one.

TEST 1: Testing The MAP Signal With A Multimeter

As mentioned in the previous section, when the MAP sensor fails, its voltage signal will not decrease/increase when vacuum is applied/released to it.

Keeping this in mind, our very first task will be to see if the MAP voltage signal decreases/increases as we manually apply/release vacuum to it.

If the MAP voltage signal does not react to the vacuum that we apply or release to the MAP sensor, then our next step is to make sure that the MAP sensor is getting 5 Volts. And we'll do this in TEST 2.

If the MAP voltage signal does react to the vacuum that we apply or release to the MAP sensor, then we can conclude that the map sensor is okay and not defective.

The wire that we're going to test is the dark green with red stripe (DK GRN/RED) wire of the MAP sensor's 3-wire connector.

In the photo above, I've labeled this wire with the number 2.

NOTE: The MAP sensor must remain connected to its electrical connector to perform this test. To access the signal voltage inside the wire, you'll need to back probe the connector or use a wire piercing probe on the wire. You can see an example of this tool here: Wire Piercing Probe.

OK, these are the test steps:

- 1

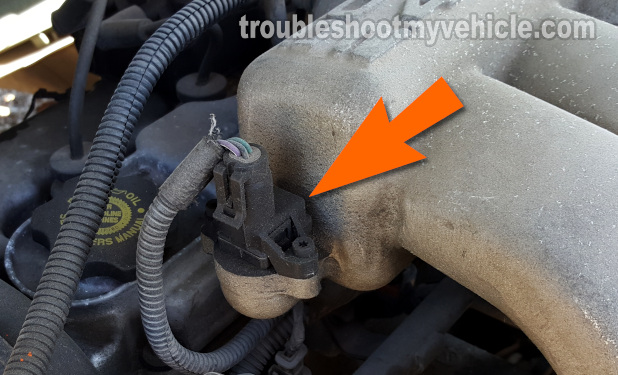

Remove the MAP sensor from its spot on the intake manifold.

Reconnect the MAP sensor to its electrical connector if you had to disconnect it to remove it from its place on the intake manifold. - 2

Connect the MAP sensor to the vacuum pump. The vacuum hose that you need to use has to fit tightly around both the vacuum pump and MAP sensor's vacuum port.

I use a spark plug wire boot that I removed from an old spark plug wire to connect my vacuum pump to the MAP sensor. - 3

Set your multimeter to Volts DC mode.

- 4

Connect the red multimeter test lead to the dark green with red stripe wire. I've labeled this wire with the number 2 in the photo above.

Remember, the MAP sensor must remain connected to its 3 wire connector. - 5

Connect the black multimeter test lead directly on the battery negative (-) post.

- 6

Turn the key on but don't start the engine. This will enable the manifold absolute pressure (MAP) sensor to get power in the form of 5 Volts from the fuel injection computer.

- 7

Your multimeter should register about 4.5 to 5 Volts DC.

- 8

Apply vacuum to the MAP sensor. Your multimeter should register a decreasing voltage that can go as low as 1.5 Volts or less.

- 9

Release the vacuum you applied to the MAP sensor. The voltage reading should go back up to the value you registered in step 7.

OK, let's take a look at what your results mean:

CASE 1: The voltage signal decreased/increased as you applied/released vacuum to the MAP sensor. This test result confirms that the manifold absolute pressure (MAP) sensor is OK (not defective). No further testing is required.

Now, if a MAP sensor trouble code is lighting up the check engine on your instrument cluster, take a look at this section: MAP Code Won't Go Away.

CASE 2: The voltage signal DID NOT decrease/increase as you applied/released vacuum to the MAP sensor. This test result usually tells you that the MAP sensor is bad. But before replacing it, you need to make sure that it's getting 5 Volts and Ground.

Your next step is to make sure that the violet with white stripe (VIO/WHT) wire is supplying the MAP sensor with 5 Volts. Go to: TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.

CASE 3: Your multimeter DID NOT register any voltage. This usually means that the MAP sensor is fried. To be absolutely sure, I suggest confirming that the MAP sensor has power and Ground. If both (power and Ground) are present, the MAP is bad. To test for power, go to: TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.