This article will help you to troubleshoot the Chrysler 2.7L, 3.3L, 3.5L crankshaft position sensor (or code: P0320) with a simple but very accurate test using only a multimeter in Volts DC.

In case you're wondering if the crankshaft position sensor can be tested with a simple multimeter resistance test? The answer is No, since it's a Hall Effect type sensor. The good news is that the test you'll learn here is easy to do and you'll get an accurate result that will either condemn the crankshaft position sensor as the cause of the no-start or exonerate it.

Contents of this tutorial:

This article covers vehicles from Chrysler, Dodge, Eagle, and Plymouth. To see if this article applies to your specific vehicle, look for the box (on the column on the right) titled 'Applies To:', and click on the 'next >>' link to scroll.

Crank Sensor Working Theory

The crankshaft position sensor senses the exact position of the crankshaft and sends this info to your vehicle's fuel injection computer (whose real technical name is: Powertrain Control Module -PCM).

This info helps the computer calculate the correct time to fire the spark plugs, pulse the fuel injectors, advance or retard timing, keep the fuel pump activated (among a few things).

The crankshaft position sensor, on your Chrysler 2.7L, 3.3L, or 3.5L equipped car, is a Hall-Effect three wire crankshaft position sensor. What this means: it produces an ON/OFF DC voltage signal that can be easily measured with a multimeter, an oscilloscope, and even an LED Light.

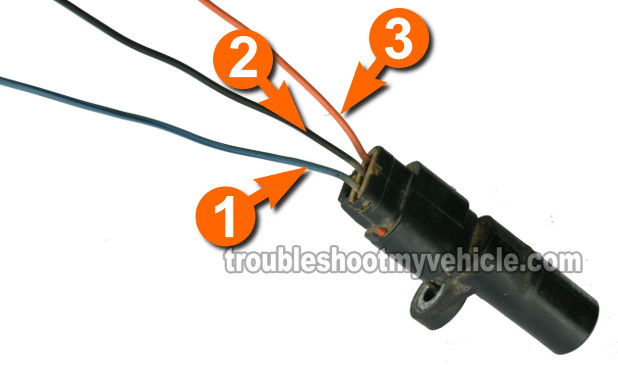

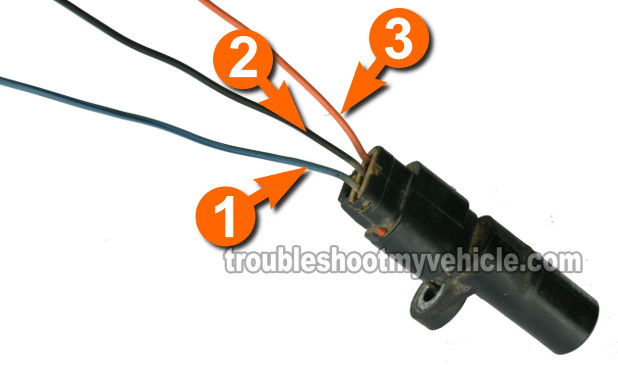

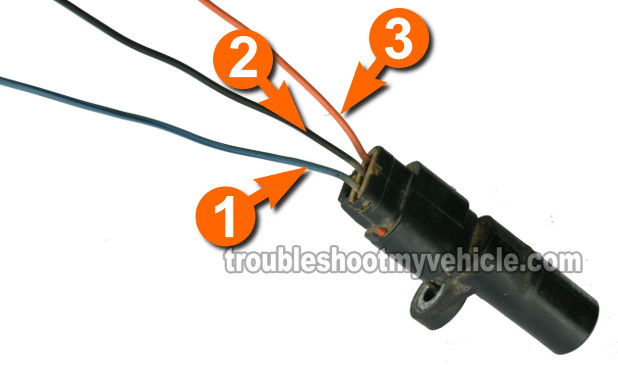

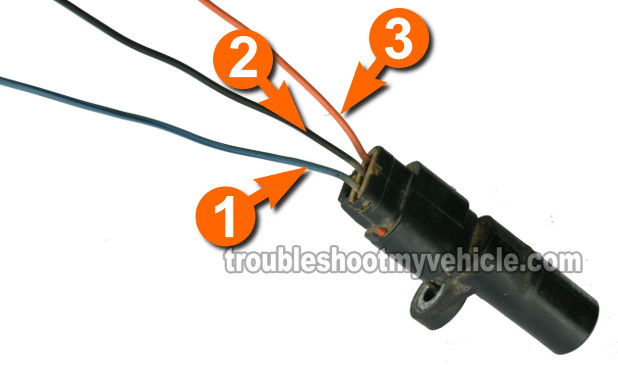

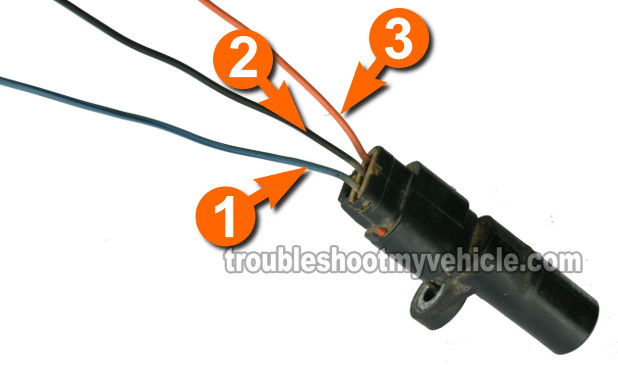

Each one of the three wires that connect to it have a specific job to do:

- The wire labeled with the number 3 delivers power in the form of 5 or 8 Volts from the PCM.

- The wire labeled with the number 2 delivers Ground. This Ground is provided inside the PCM, too.

- The wire labeled with the number 1 delivers the signal, that the crankshaft position sensor creates, to the PCM.

The most important thing to know, is that if the crankshaft position sensor goes bad, your Chrysler (or Dodge or Plymouth or Eagle) vehicle will crank but not start.

You'll also see the following symptoms:

- No spark from any of the COP ignition coils.

- No fuel injector pulses (as tested with a fuel injector Noid light).

- ASD relay doesn't stay activated beyond the initial 5 to 10 seconds the engine is being cranked by the starter motor.

CRANK SENSOR TEST 1: Verifying The Crank Sensor Signal With A Multimeter

The very first thing you'll do is to confirm that the crankshaft position sensor is creating a crank position signal.

Now, just to give you a little background info on how the crankshaft position sensor works: The PCM (Powertrain Control Module= Fuel Injection Computer) provides it with power And Ground and also a 5 Volt feed on the crank signal circuit. The crank signal, if it's working correctly, will pull down this voltage (5 V) down to 0.3 Volts or so as the engine cranks (or runs).

It's this On (5 Volts) and Off (0.3 Volts) signal that you'll be testing for with the help of the following test steps:

- 1

Disconnect the ignition coil pack from its electrical connector to disable the ignition system.

NOTE: This is important! Do not proceed with the test without first unplugging the ignition coil pack. - 2

Locate the crankshaft position sensor's connector and unplug it from the crankshaft position sensor.

Remove some of the plastic wire loom protector and/or the black electrical tape that shields the three wires of the crankshaft position sensor to gain comfortable access to the three wires it protects.

When done removing some of this black electrical tape, reconnect the connector back to the crankshaft position sensor. - 3

Place the multimeter in Volts DC mode.

- 4

Connect the red multimeter test lead to the wire identified with the number 1 in the image above.

NOTE: Remember that the crankshaft position sensor must remain connected to its electrical connector. - 5

Ground the black multimeter test lead to a good Ground point on the engine (or preferably on the battery negative (-) terminal).

- 6

When everything is set up, turn the key ON.

- 7

Turn the crankshaft pulley by hand (using the appropriate tools of course) in a clock-wise direction while you keep your eyes on the multimeter.

IMPORTANT: Do not use the starter motor to crank the engine, since this will defeat the accuracy of this test. - 8

The multimeter should register an ON/OFF voltage of 5 Volts DC.

ON is when the multimeter displays 5 Volts DC and off is 0.5 Volts DC.

NOTE: The key to seeing this voltage change is to turn the crankshaft pulley slowly and steadily.

OK, let's interpret the multimeter test results you just obtained:

CASE 1: The multimeter registered the ON/OFF 5 Volts DC as the crankshaft pulley was hand-turned. This result indicates that the crankshaft position sensor is creating a good crank signal and is working fine.

CASE 2: The multimeter DID NOT register the ON/OFF 5 Volts DC as the crankshaft pulley was hand-turned. This is not good. The sensor should have produced the indicated ON/OFF 5 Volt signal. But before we condemn the crankshaft position sensor as bad, you need to verify that it's getting power and Ground.

The next step is to check that the crankshaft position sensor is getting power. This comes in the form of either 5 Volts or 8 Volts, depending on how old your specific Chrysler (or Dodge or Plymouth or etc.) is. The PCM (Powertrain Control Module=Fuel Injection Computer) is the one that provides these 8 Volts to power the crankshaft position sensor. Go to: CRANK SENSOR TEST 2: Verifying The Crank Sensor Has Power.

CRANK SENSOR TEST 2: Verifying The Crank Sensor Has Power

In this test step, you're going to verify that the crankshaft position sensor is getting power. As mentioned earlier, this power comes in the form of 5 or 8 Volts from the PCM. Don't worry about what specific voltage your specific vehicle should output since it will be either one or the other.

IMPORTANT: You got to be very careful not to short this wire to Ground since you run the risk of damaging the PCM. Also, do not use a test light to verify this voltage, use a multimeter.

Alright, let's get to it:

- 1

Disconnect the CKP sensor from its 3-wire connector.

- 2

Place your multimeter in Volts DC mode.

- 3

Probe the front of the female terminal that connects to the wire identified with the number 3 with the red multimeter test lead.

- 4

Ground the black lead of the multimeter to a good Ground point on the engine (preferably on the battery negative (-) terminal).

- 5

When everything is set up, have your helper turn the key to the ON position but don't crank or start the engine.

- 6

Your multimeter should register 5 or 8 Volts.

OK, let's interpret the multimeter test results you just obtained. Choose from the CASES below that best match your specific results:

CASE 1: The multimeter registered 5 or 8 Volts DC when the key was turned On. This let's you know that the crankshaft position sensor is being fed with power (8 Volts) from the PCM. There is still one more test to do, before we can condemn the crankshaft position sensor as bad, and that is to test the Ground circuit. Go to: CRANK SENSOR TEST 3: Verifying The Crank Sensor's Ground.

CASE 2: The multimeter DID NOT register 5 or 8 Volts DC when the key was turned On. Recheck your connections and try the test again.

If the multimeter still does not register 8 Volts, then this result lets you know that the reason there was no ON/OFF 5 Volt signal, registered in TEST 1, is because the crankshaft position (CKP) sensor is not getting power. You have now eliminated the crankshaft position sensor as the cause of the no-start condition.

Solving the issue that is causing these missing 5 or 8 Volts will solve the no-start condition of your Chrysler 2.7L, 3.3L, or 3.8L equipped car.

CRANK SENSOR TEST 3: Verifying The Crank Sensor's Ground

In this test step, you're going to verify that the crankshaft position sensor is getting Ground. As mentioned earlier, the Ground path is completed inside the PCM.

IMPORTANT: You got to be very careful not to short this wire to power (battery voltage) since you run the risk of damaging the PCM. Also, do not use a test light to verify this voltage, use a multimeter.

OK, to get this kettle boiling, this is what you need to do:

- 1

Disconnect the CKP sensor from its 3-wire connector.

- 2

Place your multimeter in Volts DC mode.

- 3

Probe the front of the female terminal that connects to the wire identified with the number 2 with the black multimeter test lead.

- 4

Connect the red multimeter test lead to the battery positive (+) terminal.

- 5

When everything is set up, have your helper turn the key to the ON position but don't crank or start the engine.

- 6

Your multimeter should register 10 to 12 Volts.

Choose from the CASES below that best match your specific results:

CASE 1: The multimeter registered 10 to 12 Volts DC when the key was turned ON. Then the crankshaft position sensor is getting a good Ground. This results confirms that the crankshaft position (CKP) sensor is bad. Replace the crankshaft position sensor.

The CKP sensor is bad and needs to be replaced if you have:

- Confirmed the CKP is not generating an ON/OFF signal (TEST 1).

- Confirmed the CKP is getting power (TEST 2).

- Confirmed the CKP is getting Ground (this test section).

CASE 2: The multimeter DID NOT register 10 to 12 Volts DC when the key was turned On. Recheck your connections and try the test again.

If the multimeter still does not register 12 Volts, then this result lets you know that the crank does not have a good sensor Ground. You have now eliminated the crankshaft position sensor as the cause of the no-start condition, since without this Ground, the crankshaft position sensor will not work.

Related Test Articles

I have written quite a bit about the 3.3L, 3.5L ignition systems. You can find a complete list of all of these articles here: Chrysler 2.7L, 3.3L, 3.5L, 3.8L Index Of Articles.

Here's a small sample of the articles you'll find in the index:

- How To Troubleshoot A Misfire (Chrysler 2.7L, 3.2L, 3.5L).

- How To Test Diagnostic Trouble Code P0750 (Low Reverse Shift Solenoid Malfunction).

If this info saved the day, buy me a beer!