TEST 2: Making Sure The Crank Sensor Has Power And Ground

If the crank sensor is not producing an ON/OFF voltage, then the next we need to do (before condemning it as defective) is to make sure its getting power and Ground.

Depending on the year of your specific mini-van, power will be in the form of 5 Volts DC or 8 Volts DC. Both power and Ground come directly from the fuel injection computer.

IMPORTANT: Be careful and don't short the Ground wire to battery power or you'll fry the fuel injection computer. The multimeter voltage test suggest below (for testing the Ground circuit) is a safe and accurate test.

OK, these are the test steps:

- 1

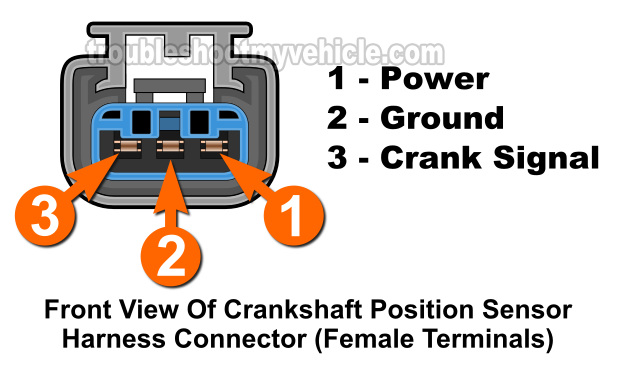

Verify that the ORG wire that connects to terminal #1 of the connector has 5 Volts (or 8 Volts) DC with the key on but engine off.

1.) Connect the red multimeter test lead (using the appropriate tool) to the wire that connects to terminal #1 of the crank sensor harness connector.

2.) Connect the black multimeter test lead to the negative (-) battery terminal.

3.) Your multimeter should read 4.5 to 5 Volts DC (or 7.5 to 8 Volts DC). - 2

Verify that the BLK/LT BLU wire that connects to terminal #2 of the connector has Ground with the key on but engine off.

1.) Connect the black multimeter test lead (using the appropriate tool) to the wire that connects to terminal #2 of the crank sensor harness connector.

2.) Connect the red multimeter test lead to the positive (+) battery terminal.

3.) Your multimeter should read 10 to 12 Volts DC.

Let's take a look at what your test results mean:

CASE 1: The crank sensor is getting power and Ground. This is the correct and expected test result.

You can now conclude that the crankshaft position is defective if you have: verified that it is NOT producing its ON/OFF signal and that IT IS getting power and Ground.

CASE 2: The crank sensor IS NOT getting power. This lack of power will stop the crank sensor from functioning.

Although it's beyond the scope of this tutorial to check for this missing power, your next step is to find out why it's missing and restore it.

CASE 3: The crank sensor IS NOT getting power. This lack of Ground will stop the crank sensor from functioning.

Although it's beyond the scope of this tutorial to check for this missing Ground, your next step is to find out why it's missing and restore it.

More 3.0L Chrysler Tutorials

You can find a complete list of tutorials in this index: Chrysler 3.0L Index Of Articles.

- How To Replace The Distributor (1988-2000 3.0L Chrysler).

- How To Test The MAP Sensor (1991-1995 3.0L Chrysler).

- How To Test The Throttle Position Sensor (1991-1995 3.0L Chrysler).

- How To Test For A Broken Timing Belt (1998-2000 3.0L SOHC Chrysler).

- Ignition Distributor System Tests 3.0L Chrysler, Dodge, Plymouth (at: easyautodiagnostics.com).

If this info saved the day, buy me a beer!