A bad fuel pump can make your minivan either not start or run like it's running out of steam. Thankfully, we can easily diagnose these issues with a fuel pressure test.

In this tutorial, I'll show you how to test fuel pressure with a fuel pressure test gauge, and I'll also walk you through a quick Starting Fluid spray test to help confirm a fuel delivery issue causing the engine to not start.

With the results of your tests —you'll be able to tell if your pump is dead, weak, or working fine.

So, whether the engine refuses to start or just feels starved of power, this tutorial will help you get to the bottom of it.

Contents of this tutorial:

- Symptoms Of A Bad Fuel Pump.

- Where To Buy A Fuel Pressure Test Gauge.

- Fuel Pressure Specifications.

- TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge.

- TEST 2: Using Starting Fluid To Diagnose A No-Start Condition.

- Checking The Fuel Pump Fuse And Power At Relay Terminal 30.

- More 3.0L V6 Dodge And Plymouth Minivan Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Dodge Caravan: 1996, 1997, 1998, 1999.

- 3.0L V6 Dodge Grand Caravan: 1996, 1997, 1998, 1999.

- 3.0L V6 Plymouth Voyager: 1996, 1997, 1998, 1999.

- 3.0L V6 Plymouth Grand Voyager: 1996, 1997, 1998, 1999.

ENGINE NO-START DIAGNOSTICS:

FUEL PUMP TEST TUTORIALS:

- How To Test The Fuel Pump (1994-1995 3.0L V6 Dodge And Plymouth Minivan).

- How To Test The Fuel Pump (2000 3.0L V6 Dodge And Plymouth Minivan).

Symptoms Of A Bad Fuel Pump

The fuel pump's job is to feed the engine a steady supply of fuel at the right pressure. When it starts to fail, everything goes downhill fast.

If the fuel pump gives out completely, the engine won't start at all —you'll just get a no-start with nothing but cranking.

But if it's starting to die slowly, you might notice that the engine stalls under load or struggles to stay running.

What do I mean by "under load"? Think hills, hauling extra passengers, or even just turning on the A/C —anything that demands more from the engine. A weak pump can't keep up, and that shows up as hesitation, stalling, or loss of power.

Other things to keep an eye (or ear) on:

- Rough idle: Idle feels uneven or shaky.

- Extended engine cranking: The engine takes longer to fire up than normal.

- No power: The van feels sluggish when you try to accelerate.

- Backfires: You hear a backfire coming from the intake area —a lean mixture symptom.

- P0171 DTC: Check engine light comes on with a P0171 (lean condition) diagnostic trouble code (DTC).

Where To Buy A Fuel Pressure Test Gauge

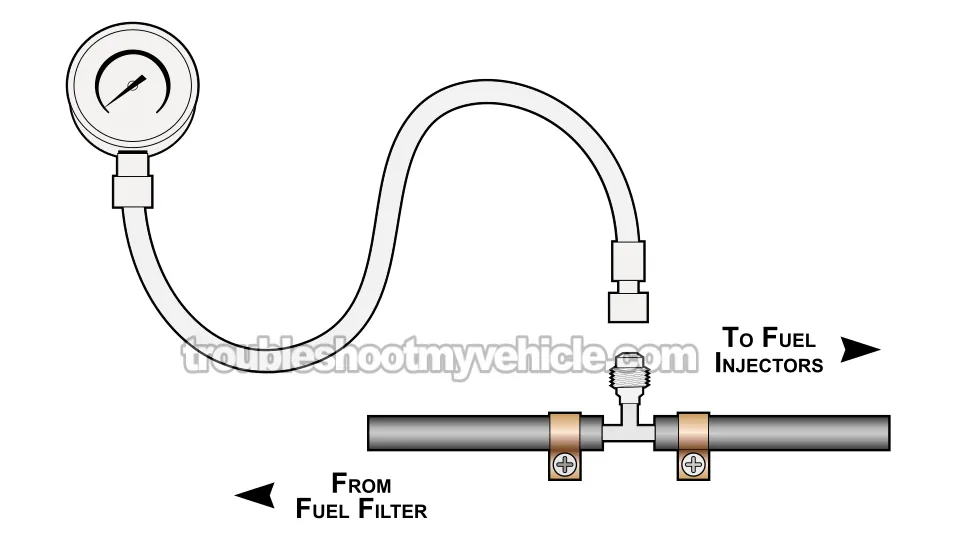

Unlike some of the other engines in these models, the 3.0L V6 doesn't have a built-in Schrader valve for measuring fuel pressure.

To hook up a fuel pressure gauge, you'll need a special adapter —a "double-ended barbed hose adapter". This adapter fits between the rubber fuel supply hose and the injector fuel rail inlet line (so the gauge can tap into the system).

The fuel pressure kits listed below include this specific adapter, making the job possible:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Fuel Pressure Specifications

| 1996-1999 3.0L V6 Fuel Pressure Spec | ||

|---|---|---|

| Year | KOEO | KOER |

| 1996-1999 | 49 ± 2 PSI | Not Given |

- KOEO = Key On Engine Off.

- KOER = Key On Engine Running.

TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge

Normally, you'd check fuel pressure by using a scan tool with bidirectional controls —you just tell the fuel pump to turn on.

If you have that type of scan tool, awesome. If not, don't sweat it —we can still check the fuel pump's pressure output.

What we'll do is bypass the fuel pump relay with a simple jumper wire, and I'll show you how to do it to get the same result (of activating the fuel pump) as the scan tool.

IMPORTANT: Always match the thickness of your jumper wire to the relay's male spade terminals —too thick, and you risk damaging the female terminals inside the relay socket, which can cause connection issues down the road.

These are the fuel pressure test steps:

- 1

Lay a clean shop towel underneath the area where the rubber supply hose connects to the fuel rail.

This is to absorb any fuel that is going to leak in the next step. - 2

Disconnect the rubber fuel supply hose from the injector rail's inlet port.

- 3

Connect the double-ended barbed hose adapter using the short rubber hose to the fuel rail inlet and secure it with its hose clamp.

- 4

Reconnect the fuel supply hose to the other side of the adapter and snug down the clamp.

- 5

Connect your fuel pressure gauge to the hose adapter.

- 6

Locate the fuel pump relay under the hood and remove it.

- 7

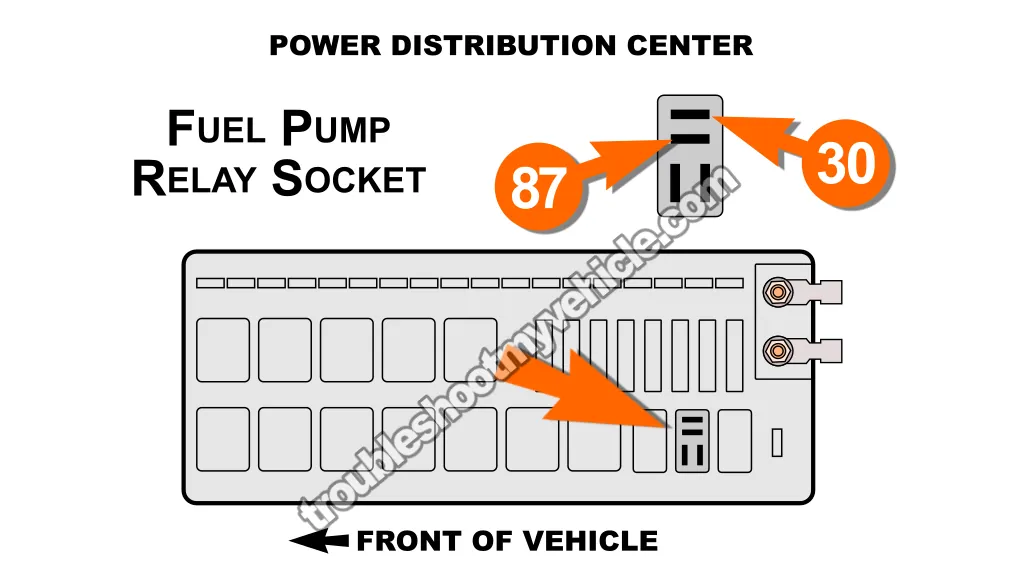

Use a jumper wire to bridge terminals 30 and 87.

NOTE: This will immediately and directly power up the fuel pump.

Check all your hose connections for leaks.

If you see fuel leaking, remove the jumper wire, and go back and tighten things up. - 8

Your gauge should show about 49 ± 2 PSI when the system is pressurized.

This is what that fuel pressure test result means:

CASE 1: Pressure is spot-on, right around 49 ± 2. Your fuel pump is doing exactly what it's supposed to.

If the engine won't fire up or lacks power, you'll need to dig into ignition, compression, or sensor issues instead.

CASE 2: Reading is below expected fuel pressure. That tells you the pump is getting failing and can't build enough pressure to meet demand. Replace the fuel pump.

CASE 3: Gauge reads 0 PSI. That's tells you the engine no-start issue is due to a lack of fuel delivery.

The next step is to make sure terminal 30 at the fuel pump relay socket actually has power. It should have 10 to 12 Volts at all times —even with the key off. Go to: Checking The Fuel Pump Fuse And Power At Relay Terminal 30.

TEST 2: Using Starting Fluid To Diagnose A No-Start Condition

This is always my first move when I'm diagnosing an engine that won't start. It's quick, simple, and helps me figure out if I'm dealing with a fuel issue right out of the gate.

But before I ever spray starting fluid into the throttle body, I make sure every spark plug wire is actually firing spark.

If there's no spark, this test won't tell you much —so I always confirm spark first (and you need to do the same).

Now, this test isn't a replacement for checking fuel pressure with a gauge —not even close. But it's a great starting point that helps me point the rest of the diagnostic in the right direction.

IMPORTANT: The accuracy of this test depends on all six spark plug wires firing spark. So before you reach for the carb cleaner or starting fluid, confirm that all six cylinders are getting spark. TEST 1 of this tutorial will help you with the spark test:

Let's get testing:

- 1

Loosen the air intake clamp.

Don't take it all the way off —just loosen it enough to slide the duct off the throttle body opening. - 2

Open the throttle plate and spray some starting fluid into the throttle bore.

A good and solid 1 to 2 second burst of spray will suffice. - 3

Put the intake duct back on.

You don't need to re-tighten the clamp —just seat the duct well enough to get a sealed air path. - 4

Try starting the engine as soon as the duct is back on the throttle body.

Having an assistant crank the engine helps. - 5

Pay attention to how the engine reacts:.

1.) If the engine starts and stalls, you've got a fuel delivery issue.

2.) If it doesn't start at all, the problem lies elsewhere.

Here's what's going on:

CASE 1: Engine fired up for a second, then stalled. That quick start means the engine Can run —you just gave it the fuel it wasn't getting.

This test result points to a weak or dead fuel pump. Jump over to TEST 1 and check the pressure to confirm: TEST 1: Checking Fuel Pressure With A Fuel Pressure Gauge.

CASE 2: Engine just spun over without catching. If the engine didn't even hiccup, odds are you're dealing with a non-fuel-related issue.

That rules out the pump and injectors —it's time to look at spark, timing belt, engine mechanical as the source of the engine no-start problem.

Checking The Fuel Pump Fuse And Power At Relay Terminal 30

When your fuel pressure gauge stays at zero PSI (TEST 1), we can generally assume the pump has failed —but before dropping the tank or ordering parts, we need to check that the pump is getting power.

The power to the fuel pump comes from terminal 30 in the relay socket, and that terminal should always have 12 Volts.

This "always HOT" voltage comes directly from the fuel pump fuse located in the same underhood fuse box (as the fuel pump relay), whether or not the key is in the ON position:

- 1996–1997: Fuse #13 (20 Amp).

- 1998–1999: Fuse #16 (20 Amp).

Use a test light or digital multimeter to confirm voltage at terminal 30. If there's no power, pop out the fuel pump and inspect it.

If the fuse is blown, replace it, but take note —a bad fuel pump can cause a fuse to blow due to high current draw caused by internal wear.

If you install a new fuse and it immediately blows again (even if the engine starts and runs), that's your red flag —the fuel pump is toast.

If the fuse is good, terminal 30 has 10 to 12 Volts, but the pressure gauge still reads zero, then the pump has power but isn't doing its job. Time to replace it.

More 3.0L V6 Dodge And Plymouth Minivan Tutorials

You can find a complete list of 3.0L V6 Dodge and Plymouth minivan tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- How To Replace The Distributor (1988-2000 3.0L V6 Chrysler, Dodge, Plymouth).

- How To Test For A Broken Timing Belt (1988-2000 3.0L SOHC Chrysler).

- How To Test Engine Compression (1987-2000 3.0L V6 Chrysler, Dodge, Plymouth).

- How To Test For A Blown Head Gasket (1991-2000 3.0L Caravan, Grand Caravan, Voyager, Grand Voyager).

If this info saved the day, buy me a beer!