TEST 3: Manually Inducing A Lean Air/Fuel Mixture

To find out if the rear O2 sensor is working properly, we need to see if it can detect a lean condition in the exhaust.

We'll do this by carefully introducing a small vacuum leak —specifically, by slightly opening the brake booster vacuum hose while the engine is running.

This is gonna let unmetered air into the intake manifold, leaning out the air/fuel mixture and changing the composition of the exhaust gases flowing into the catalytic converter.

If the sensor is functioning as it should, it'll immediately respond by dropping its voltage reading to 0.2 Volts or lower.

NOTE: You don't have to use the brake booster vacuum hose specifically. Any vacuum hose connected to the intake manifold —as long as it's about the same diameter as the brake booster hose— can be used for this test if it's easier to reach. Just make sure it's not a small-diameter hose; it needs to be the size of the brake booster's vacuum supply line to create a noticeable lean condition.

Alright, let's get going:

- 1

With the engine OFF, disconnect and re-seat the brake booster vacuum hose to break the seal.

NOTE: It's best to do this before the actual test, so you don't have to wrestle with the vacuum hose while the engine is running. - 2

Start the engine and allow it to reach operating temperature.

- 3

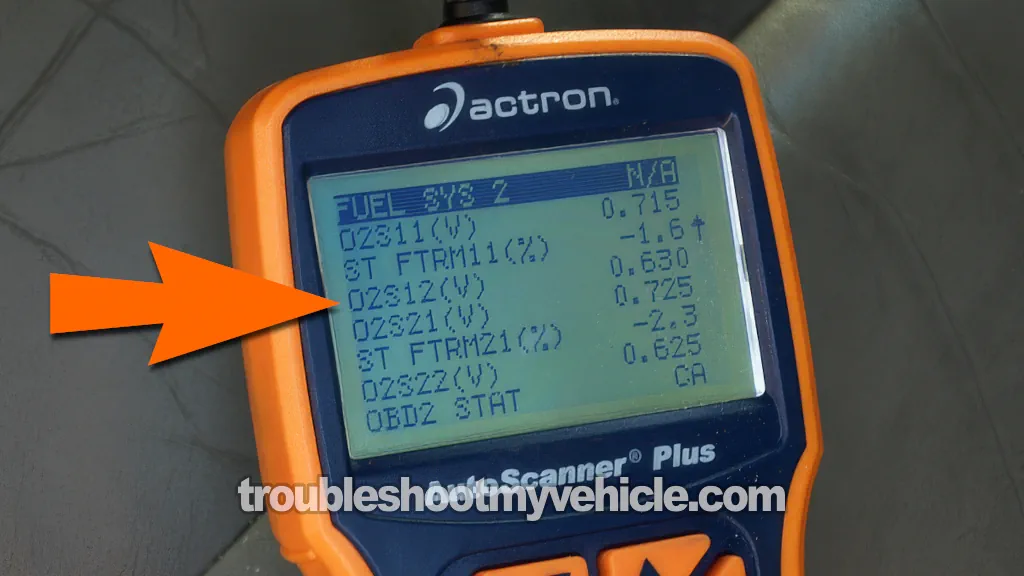

Enter live data mode on your scan tool and confirm closed loop operation.

- 4

Find and monitor the values of PID O2S12.

Remember, PID O2S12 is the rear oxygen sensor parameter ID. - 5

Slightly crack open the brake booster hose to introduce a small vacuum leak.

NOTE: If you pull the hose off completely, the engine will stall (shut down). You want a small, controlled leak.

If the engine stalls, reseat the hose, restart the engine, and try again with a smaller opening. - 6

Watch for the O2 sensor voltage to drop below 0.2V or less.

- 7

When done, reconnect the hose and shut off the engine.

CASE 1: Voltage immediately drops below 0.2V. Nice! The rear O2 sensor is working —it successfully detected the lean condition.

Next, we'll run our final oxygen sensor performance test to see if it can also respond to a rich condition. Go to: TEST 4: Manually Inducing A Rich Air/Fuel Mixture.

CASE 2: Voltage stays steady. This result confirms the rear O2 sensor is faulty. Replace the sensor and repeat the test.

One last thing: even though you've confirmed the sensor is bad —it won't trigger a P0420 DTC. Only a failing catalytic converter can do that.

So, after replacing the sensor, clear the codes, road test your minivan, and wait to see if the P0420 returns (it may take a day or two). If it does, the catalytic converter is bad and needs to be replaced.

TEST 4: Manually Inducing A Rich Air/Fuel Mixture

To complete the rear O2 sensor check, we'll introduce a temporary rich condition by spraying carburetor cleaner into the throttle body.

If you don't have carb cleaner, starting fluid spray or brake cleaner spray can also be used —they'll all enrich the air/fuel mixture for the test.

This should cause the O2 sensor to immediately spike above 0.5V if it's working correctly.

SAFETY CAUTION: Always spray in a well-ventilated area, away from hot surfaces and ignition sources. Keep a fire extinguisher nearby. Also, a quick burst is all that's needed —otherwise you'll flood the engine and it'll stall.

OK, time to roll up our sleeves:

- 1

Remove the air duct from the throttle body.

- 2

Start the engine and let it warm up.

- 3

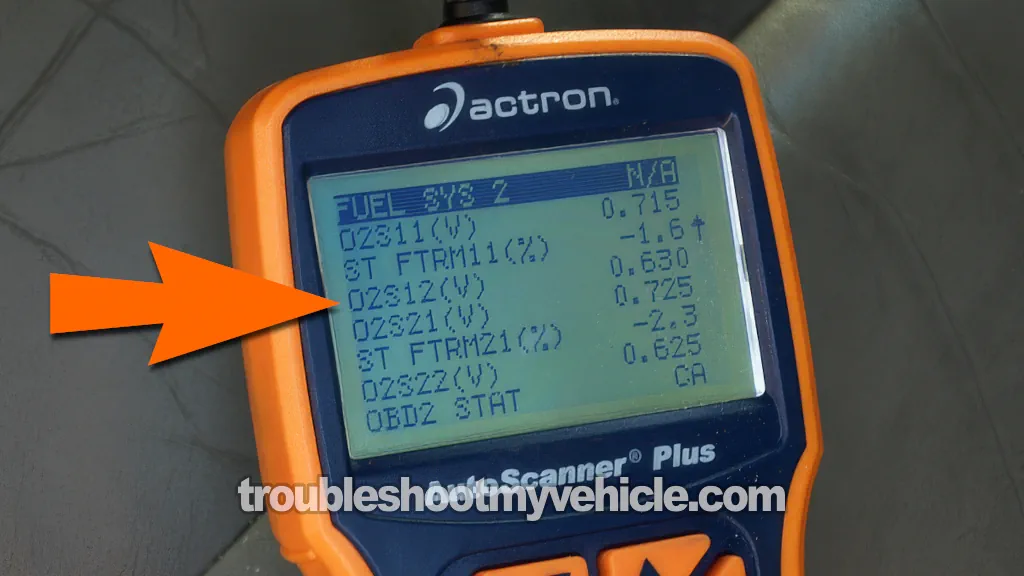

In your scan tool's live data mode, confirm the PCM is in closed loop mode.

- 4

Scroll and find the O2S12 PID and monitor the values shown.

- 5

Spray a short burst (½ to 1 second) of carb cleaner into the throttle body.

If the engine stalls, you sprayed too much. No worries —just restart the engine, let it idle for a minute or two to clear out the excess, and repeat the test with a shorter spray burst. - 6

Watch for a voltage spike above 0.5V — in reality, it should spike to 0.9V or higher.

- 7

Wait for the engine to stabilize before repeating to confirm the O2 sensor's response one more time.

Avoid flooding the engine.

Let's interpret your test result:

CASE 1: Voltage spikes to 0.9 Volts or higher. This is the correct and expected test result.

At this point, you've confirmed that the rear O2 sensor is working properly —it can detect both lean and rich conditions. That means the P0420 code is legitimate, and the catalytic converter is no longer doing its job. It needs to be replaced.

Just to clarify: the P0420 DTC does not point to a faulty oxygen sensor. There are specific trouble codes for that. When you see P0420, it's the catalytic converter itself that's being flagged as inefficient.

Keep in mind, catalytic converters can wear out on their own with age and mileage —but you've also got to make sure there's no ongoing engine mechanical issue (like burning oil or coolant) or fuel system problem (like a rich-running condition) that contributed to its failure. Otherwise, the new cat will eventually suffer the same fate.

CASE 2: Voltage did not spike at all. This tells us the rear O2 sensor isn't responding and that it's toast.

Go ahead and replace the sensor, then repeat the test to confirm it now reacts properly to changes in the air/fuel mixture.

I do want to point out that a bad rear O2 sensor by itself does not set a P0420 code. That code is reserved for catalytic converter efficiency issues.

So after swapping out the sensor, clear any stored codes and take your minivan for a road test. If the P0420 comes back —and it might take a few drive cycles— that's your confirmation the catalytic converter is failing and needs to be replaced.

Understanding "Rich" And "Lean" O2 Sensor Signals

When doing any diagnostic work involving oxygen sensors or catalytic converters, you're gonna see the terms rich and lean thrown around often.

These two terms describe the balance of fuel and oxygen in the combustion process —and more importantly, how much oxygen is left in the exhaust gases afterward.

Let's break it down clearly:

- Rich mixture: This means there's too much fuel and not enough oxygen in the exhaust. The oxygen sensor will show a high voltage reading, usually between 0.8 and 0.9 Volts.

- Lean mixture: This means there's excess oxygen and not enough fuel. The O2 sensor's voltage will drop to a low value —typically in the 0.1 to 0.2 Volt range.

The front oxygen sensor (before the catalytic converter) is designed to constantly toggle between rich and lean readings. This switching action tells the PCM how to adjust the air/fuel ratio in real time for efficiency and emissions control.

The rear sensor (after the converter), however, works differently. If the catalytic converter is doing its job, it filters out hydrocarbons and other pollutants from the exhaust —reducing the amount of unburned fuel reaching the sensor. As a result, the rear sensor produces a steadier signal, with slower, broader swings between lean and rich.

But when the rear sensor stays consistently high (above 0.5V) and barely moves, that's a warning sign. It likely means the converter is no longer cleaning the exhaust —and that's when the PCM will often trigger a P0420 code.

The important thing to keep in mind is that we're just not watching for specific voltage numbers —we want to see how the signal behaves. A flat high reading from the rear O2 sensor, while the front sensor keeps switching normally, is a strong indication the catalytic converter is on its way out.

What "Closed Loop" Means —And Why It Matters

When you start your minivan —and the engine is still cold (meaning it hasn't been running and is cold to the touch, regardless of the weather outside)— the PCM (Powertrain Control Module) enters what's called open loop mode.

During open loop, the PCM doesn't rely on feedback from the oxygen sensors. Instead, it uses fixed programming to manage fuel delivery. Think of it as the system running on autopilot until the engine reaches its normal operating temperature.

Once the engine warms up, the PCM switches to closed loop mode. Now it begins using real-time data from the oxygen sensors and other inputs to fine-tune the air/fuel mixture continuously. This helps reduce emissions, improve driveability, and optimize fuel efficiency.

Here's why this matters: If you're diagnosing a catalytic converter issue or checking how the downstream O2 sensor is behaving, the engine must be in closed loop. Otherwise, the data you're seeing won't be accurate.

Most scan tools display this status directly. Look for a line labeled something like “Fuel System Status” —it should say “Closed Loop” before you begin any sensor tests.

In conclusion, it's best not to trust sensor readings if the engine is still cold. Always let it warm up fully, confirm it's in closed loop, and then proceed with testing.

More 3.0L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials

I've written several more tutorials for the 3.0L V6 Chrysler, Dodge, and Plymouth minivans that you might find helpful. You can browse them all in this index:

If this info saved the day, buy me a beer!