The EVAP purge solenoid on your 1998-2000 3.3L V6 Dodge Caravan, Grand Caravan, Voyager, or Grand Voyager can very easily be tested and the best part is that no scan tool is required.

In this tutorial, I'll explain how this solenoid works, common failure points, and the typical symptoms —including P0441 and P0443 codes— that show up when things go wrong.

It's a quick and easy test you can do yourself without taking it to the shop —and it could save you from unnecessary parts replacement.

Contents of this tutorial:

- How The EVAP Purge Solenoid Works.

- Why EVAP Purge Solenoids Fail.

- Symptoms Of A Bad EVAP Purge Solenoid.

- TEST 1: Inspecting The Purge Solenoid Hoses.

- TEST 2: Bench-Testing The EVAP Purge Solenoid (No Scan Tool Required).

- What To Do If The Solenoid Tests Good (But The Code Keeps Coming Back).

- More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.3L V6 Chrysler Town & Country: Late 1998, 1999, 2000.

- 3.3L V6 Dodge Caravan: Late 1998, 1999, 2000.

- 3.3L V6 Dodge Grand Caravan: Late 1998, 1999, 2000.

- 3.3L V6 Plymouth Voyager: Late 1998, 1999, 2000.

- 3.3L V6 Plymouth Grand Voyager: Late 1998, 1999, 2000.

EVAP SYSTEM WIRING DIAGRAM:

OTHER EVAP PURGE SOLENOID TUTORIALS:

- EVAP Purge Solenoid Tests -P0441, P0443 (1996-1998 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- EVAP Purge Solenoid Tests -P0441, P0443 (2001-2007 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

How The EVAP Purge Solenoid Works

If you're chasing down a P0441 or P0443 trouble code on your 1998-2000 3.3L V6 Dodge Caravan, Grand Caravan, Voyager, or Grand Voyager, a good place to start is understanding what the EVAP purge solenoid does —and why it matters.

Whenever gasoline sits in your tank, it naturally gives off vapors. The EVAP (Evaporative Emission Control) system captures those vapors and stores them in a charcoal canister. The purge solenoid is the electronic valve that the PCM uses when it decides when those trapped vapors get pulled into the engine and burned off during normal operation.

Here's how it works:

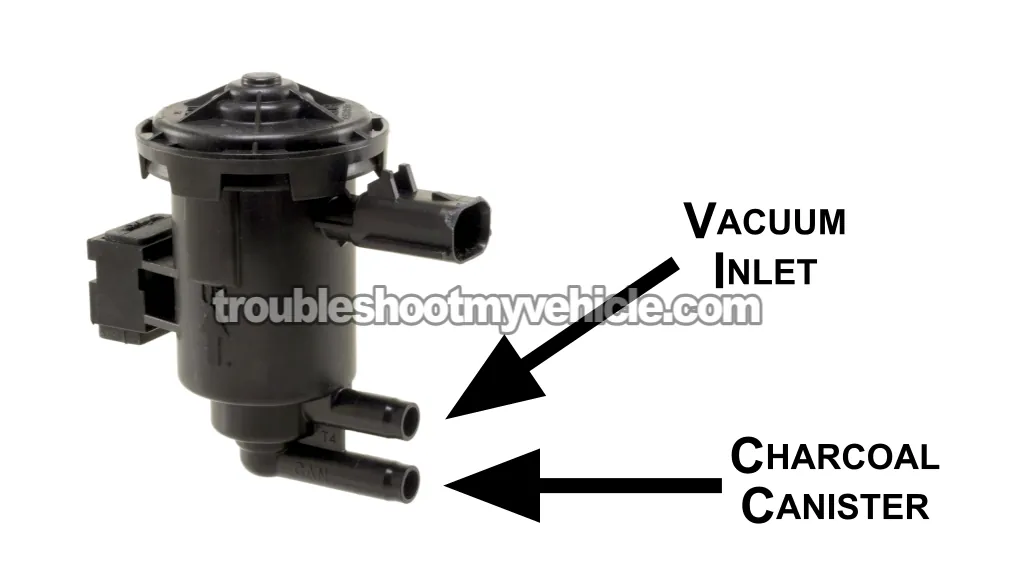

- The solenoid sits between the intake manifold and the charcoal canister.

- The inlet hose feeds vapors from the canister to the solenoid.

- When the solenoid is closed, no vapors (or vacuum) can pass through —the valve blocks flow.

- When the solenoid opens, it unblocks flow and its outlet hose routes those vapors into the throttle body.

Opening and closing is controlled by the PCM (Powertrain Control Module), which activates the solenoid when the engine is up to temp and under the right conditions —like cruising or idling.

If the solenoid sticks or fails electrically, it disrupts the vapor flow —triggering a P0441 or P0443 fault code and turning on the Check Engine Light.

Why EVAP Purge Solenoids Fail

It's not unusual for purge solenoids to fail on these older 3.3L V6 engines as age, heat, and wear all take their toll. If you're seeing a P0441 or P0443 code, here are the most likely causes:

1) Sticking valve (mechanical issue): The internal valve inside the solenoid can stick open or closed due to dirt buildup, varnish from fuel vapors, or simple wear. This triggers a P0441 code.

2) Burned coil or wiring problems: The solenoid contains a small electric coil. If this coil burns out —or if the wiring or connectors develop cracks, broken pins, or corrosion— the PCM will detect a circuit fault and log a P0443 code.

3) Leaking vacuum line or bad rubber connectors: The vacuum and charcoal canister lines for the purge solenoid are rigid plastic tubes, connected at both ends with rubber fittings. It's common on these older vans for the plastic line to crack, or for the rubber connectors to lose their seal. This will often throw a P0441 code even if the solenoid is functioning correctly.

Symptoms Of A Bad EVAP Purge Solenoid

If the purge solenoid on your 1998-2000 3.3L V6 equipped minivan goes bad, you may not notice any major drivability problems right away. In fact, the most common symptom is simply the Check Engine Light turning on —with a stored code.

Typical fault codes related to purge solenoid problems:

- P0441: Incorrect purge flow.

- P0443: Purge solenoid circuit failure.

Less often, you might notice one or more of these minor symptoms:

- Engine runs a little rough at idle.

- Hard starting after refueling.

But here's the thing —most folks won't notice any change at all in how the minivan runs. That's why it's always a good idea to test the solenoid when these codes pop up.

TEST 1: Inspecting The Purge Solenoid Hoses

Before testing or replacing the purge solenoid, there's an easy check you should always do first —inspect the two hoses connected to it.

On these 1998-2000 minivans, the purge solenoid connects to:

- The fuel vapor charcoal canister (via the inlet hose).

- The intake manifold (via the outlet hose).

If either hose is cracked, brittle, loose, or leaking, the PCM may still set a P0441 code —even if the solenoid is working perfectly.

When inspecting the hoses, be sure to:

- Look for cracks, dry rot, or splits.

- Check for loose connections —hoses should fit tight on the solenoid ports.

- Squeeze along the length of each hose —feel for soft spots or pinholes.

Just a few minutes spent checking these hoses can save you time and frustration later if you find them to be in bad shape (and may even fix the problem without replacing the solenoid).

If the hoses connecting to the EVAP purge solenoids are OK, continue to: TEST 2: Bench-Testing The EVAP Purge Solenoid (No Scan Tool Required)

TEST 2: Bench-Testing The EVAP Purge Solenoid (No Scan Tool Required)

In this section, we're gonna bench-test the EVAP purge solenoid by applying 12 Volts and Ground from your minivan's battery (after removing it of course).

You won't need any special tools —just two jumper wires with insulated crocodile tips, and a short length of vacuum hose.

Be sure to note the orientation of the solenoid on its mounting bracket —and if necessary, label the hoses before removing the solenoid so you can reinstall them correctly.

Here's the game plan:

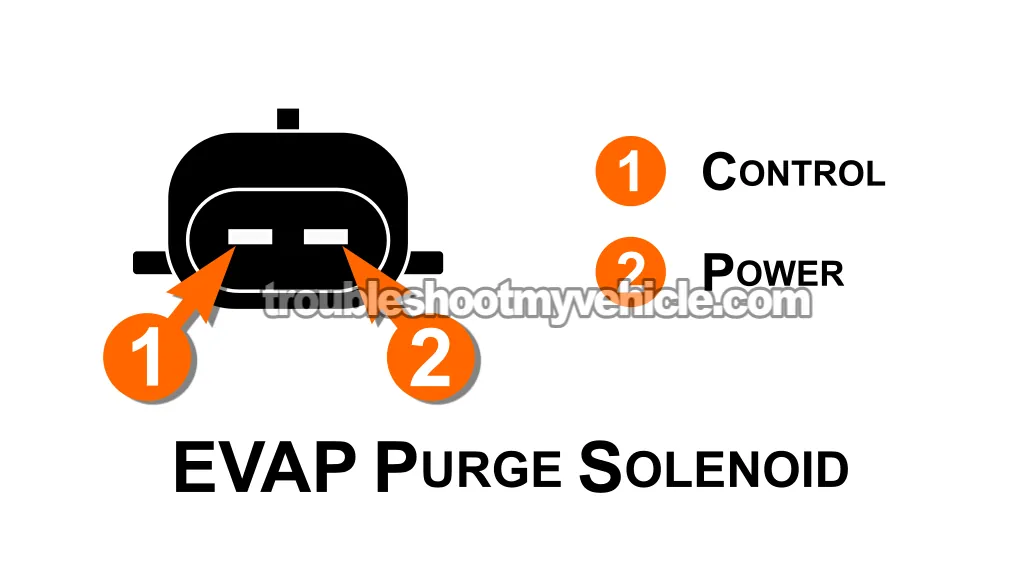

PART 1: Electrical function check

- Remove the EVAP purge solenoid from its place in the engine compartment.

- Identify the two electrical terminals on the solenoid.

- Connect one jumper wire from terminal 2 to the battery positive (+) post.

- NOTE: Use insulated alligator clip jumpers to prevent accidental shorts.

- 10 Pc. And 5 Color Insulated Alligator Clips (at: amazon.com).

- Connect the second jumper from terminal 1 to the battery negative (-) post.

- When you complete the negative (Ground) connection, the solenoid should make a distinct "click" —that's the valve opening.

- When you disconnect the Ground wire, you should hear another "click" —valve closing.

PART 2: Airflow test

- Attach a small piece of vacuum hose to the inlet port of the solenoid.

- This is the port that connects to the EVAP charcoal canister (it's usually labeled with embossed with the the word CAN).

- With the solenoid energized (powered), blow air into the hose —airflow should pass freely.

- Remove power from the solenoid —airflow should now be fully blocked.

If the solenoid fails to click, or if airflow behaves incorrectly, it's toast and needs to be replaced to resolve your P0441 or P0443 code.

What To Do If The Solenoid Tests Good (But The Code Keeps Coming Back)

So, what if your EVAP purge solenoid passes the test? It clicks, airflow is correct, and the hoses look good… but that P0441 or P0443 code keeps coming back?

Here are a few things to consider next:

- Double-check hose routing: On these minivans, it's easy to accidentally swap the inlet and outlet hoses.

- Check for vacuum at the solenoid: With the engine running, the hose connected to the VAC port (outlet) of the purge solenoid should have solid vacuum. If there's no vacuum present, you could be dealing with a clogged port or a restriction in the vacuum line to the intake manifold —which can cause EVAP flow codes.

- Electrical wiring and connector issues: Even if the solenoid clicks on the bench, there could be an intermittent wiring problem (broken pin, corrosion inside connector, damaged wire loom) causing a circuit fault during normal operation —especially for P0443 codes.

- Check the entire vapor line to the canister: Follow the vapor line from the purge solenoid to the charcoal canister:

- Make sure the line is fully seated and sealed at the canister port.

- Inspect the entire length for splits, cracks, or any kind of damage.

- Disconnect both ends and blow air through the line to check for blockages. If the charcoal canister is failing internally (it happens), charcoal can get into the line and clog it —causing EVAP system codes.

- Examine the charcoal canister: Look closely at the canister housing and ports. Any physical damage here (cracks, broken fittings) can easily trigger EVAP system codes.

If after all this, the code still won't clear —it may be time to dive deeper into the EVAP system (such as checking the leak detection pump).

More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials

You can find a complete list of tutorials in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The MAP Sensor (2001-2004 3.3L V6 Chrysler And Dodge Minivan).

- How To Test The Alternator (2001-2007 3.3L Chrysler).

- How To Test Engine Compression (1991-2010 3.3L V6 Chrysler, Dodge, Plymouth Minivan).

- How To Check For Vacuum Leaks: Carb Cleaner Spray (1991-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

If this info saved the day, buy me a beer!