Testing the CMP sensor on your 3.3L V6 minivan isn't hard at all. Best of all, you won't need a scan tool or any fancy shop equipment either, just a regular multimeter will do the trick.

I'll walk you through each test step-by-step so you can confidently figure out if the camshaft position (CMP) sensor is working or not.

This tutorial is DIYer-friendly and designed to help you zero in on the issue without guesswork.

Contents of this tutorial:

- Common Symptoms Of A Faulty CMP Sensor.

- How The CMP Sensor Works.

- Should I Just Replace The CMP Sensor Without Testing It?

- Where To Buy The CMP Sensor And Save.

- Camshaft Position Sensor Connector Pinout.

- TEST 1: Testing The CMP Signal With A Multimeter.

- TEST 2: Making Sure The CMP Sensor Is Getting 8 Volts.

- TEST 3: Making Sure The CMP Sensor Is Getting Ground.

- Installing The CMP Sensor: Air Gap Clearance.

- More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.3L V6 Chrysler Town & Country: 1990, 1991, 1992, 1993.

- 3.3L V6 Dodge Caravan: 1990, 1991, 1992, 1993.

- 3.3L V6 Dodge Grand Caravan: 1990, 1991, 1992, 1993.

- 3.3L V6 Plymouth Voyager: 1990, 1991, 1992, 1993.

- 3.3L V6 Plymouth Grand Voyager: 1990, 1991, 1992, 1993.

IGNITION SYSTEM TESTS:

- How To Test The CKP Sensor (1990-1993 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The Coil Pack (1990-1998 Chrysler 3.3L, 3.8L) (at: easyautodiagnostics.com).

WIRING DIAGRAM:

OTHER CMP SENSOR TESTS:

- How To Test The CMP Sensor (1994-1997 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The CMP Sensor (1998-2000 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test The CMP Sensor (2001-2003 3.3L V6 Chrysler And Dodge Minivan).

- How To Test The CMP Sensor (2004-2007 3.3L V6 Chrysler And Dodge Minivan).

Common Symptoms Of A Faulty CMP Sensor

When the camshaft position (CMP) sensor on your early 3.3L V6 minivan starts to fail, it can create a variety of problems that affect starting, drivability, and engine performance. Here's what to look out for:

- Engine cranks but won't start: A dead CMP sensor can leave the ignition system in the dark, preventing the engine from firing up.

- Hard starts: Sometimes the engine does start, but only after long cranking periods.

- Random stalling: Your minivan might suddenly stall while idling or driving —no warning, no pattern.

- Rough idle or misfiring: Engine may be shaking or sputtering at idle.

- Weakened power: You'll feel it —the engine doesn't have the "oomph" it used to have.

- Code 54 stored: This OBD I trouble code signals that the PCM isn't seeing a camshaft signal.

How The CMP Sensor Works

The camshaft position (CMP) sensor on the 1990-1993 3.3L V6 engines is a 3-wire Hall-Effect sensor and it plays a key role in ignition timing.

It generates a digital signal the Powertrain Control Module (PCM) uses to control fuel injection and spark timing.

Here's how it's generated when you turn the key and crank the engine:

- The CMP sensor gets power from the PCM.

- These are 8 Volts DC delivered by the orange (ORG) wire.

- The CMP sensor gets Ground from the PCM.

- This Ground is supplied by the black with light blue stripe (BLK/LT BLU) wire.

- As the engine cranks and starts, the sensor outputs a square wave signal that rapidly switches between two voltage levels.

- This ON/OFF signal is delivered to the PCM by the tan with yellow stripe (TAN/YEL) wire.

This ON/OFF signal is what the PCM uses to determine the exact position of the camshaft.

- "ON" equals a high signal of about 5 Volts.

- "OFF" is the low side of the signal —typically around 0.3 to 0.5 Volts.

Should I Just Replace The CMP Sensor Without Testing It?

A lot of folks —even professional shops— will just replace the camshaft position sensor without running any tests first.

And honestly, in most cases, that does fix the problem and clears the CMP sensor trouble code.

Since the CMP sensor isn't pricey, it's totally OK to swap it out without testing, especially if you're short on time.

If you're going this route, check the links below —they can help you save some cash on the replacement.

Now, if you're the type who wants to test before replacing anything, this tutorial's got your back with step-by-step instructions.

NOTE: If you're installing a new sensor or removing and reinstalling the same one, see: Installing The CMP Sensor: Air Gap Clearance.

Where To Buy The CMP Sensor And Save

The following links will help you comparison shop for the camshaft position sensor:

CMP Spacer: Air Gap Spacer

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

NOTE: If you're installing a new sensor or removing and reinstalling the same one, see: Installing The CMP Sensor: Air Gap Clearance.

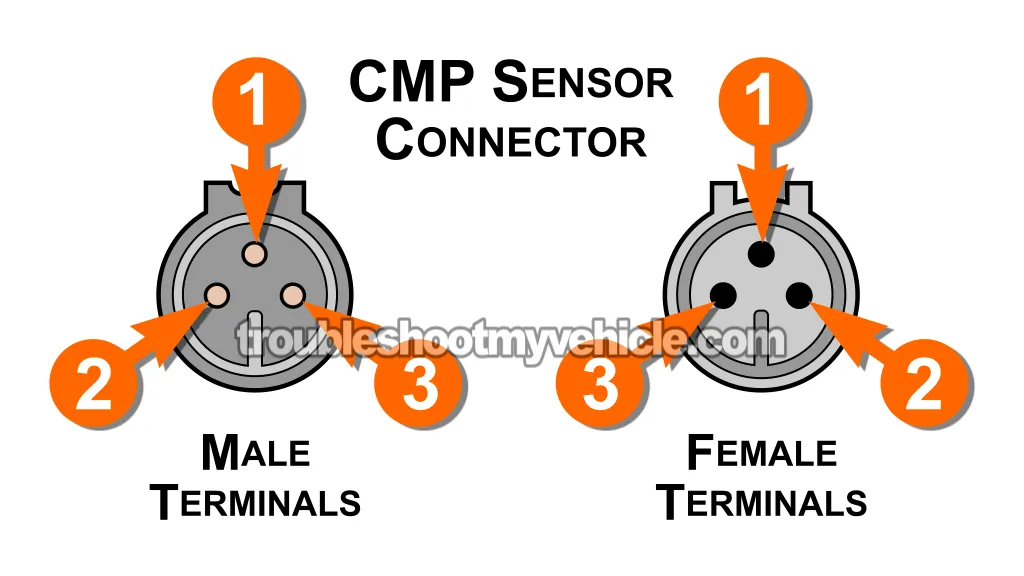

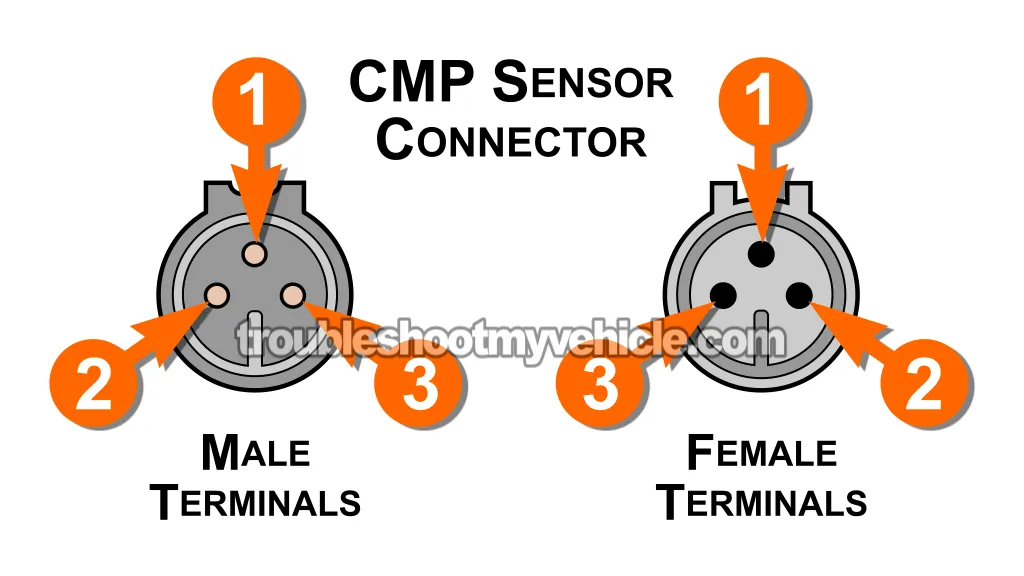

Camshaft Position Sensor Connector Pinout

| CMP Sensor Circuits | ||

|---|---|---|

| Terminal | Wire | Description |

| 1 | Orange (ORG) | 8 Volts DC |

| 2 | Black with light blue stripe (BLK/LT BLU) | Ground |

| 3 | Tan with yellow stripe (TAN/YEL) | CMP Sensor Signal |

TEST 1: Testing The CMP Signal With A Multimeter

To begin our CMP sensor diagnostic, we're gonna start with a basic signal test —specifically, checking if the CMP sensor is sending an ON/OFF voltage signal to the PCM while the engine turns.

This test doesn't require a scan tool —just a multimeter to read the CMP sensor's output voltage.

One more thing —and this one's a biggie— you'll need to turn the engine by hand. You can't use the starter motor during this test.

That's because the only way to clearly see the ON/OFF voltage pulse from the CMP sensor is by slowly turning the engine over with a ratchet and socket on the crankshaft pulley.

If you use the starter motor, it'll spin the engine too fast, and the pulses won't register on your multimeter.

If you don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

NOTE: The CMP sensor signal test is down with the sensor still plugged in, so you'll need to use either a back probe or a wire-piercing tool. You can see an example of this tool here: Wire Piercing Probe.

CAUTION: If you need to lift the front of the minivan to access the crankshaft pulley bolt, make sure to securely place the vehicle on jack stands. Never trust the jack alone to support the vehicle.

Time to dive in:

- 1

Disconnect the ignition coil pack.

This is a safety step you shouldn't skip —unplug the coil pack before doing anything else. - 2

Set your multimeter to Volts DC mode.

- 3

Connect the black test lead on the battery's negative (-) terminal.

- 4

Probe the CMP sensor's signal wire with the red multimeter test lead.

NOTE: Both CMP sensor connectors must remain connected to each other during the test.

Use a back probe on the connector or a wire-piercing probe on the wire to access the signal wire. - 5

Turn the key ON but don't crank the engine.

- 6

Manually rotate the crankshaft using a ½-inch ratchet and socket.

NOTE: Slowly turn the crank pulley clockwise while keeping an eye on the multimeter. - 7

You should see the voltage toggle between 5 Volts and 0 (0.3–0.5) Volts.

That's your ON/OFF square wave.

Let's see what this result is telling us:

CASE 1: Signal detected. Perfect —this is exactly what you want to see.

If your multimeter showed the ON/OFF pattern while slowly turning the crankshaft pulley, it means the CMP sensor is working correctly.

Since it's producing the expected square wave signal, it also confirms it's receiving power and Ground from the PCM.

CASE 2: No signal detected. Let's double-check things.

First, make sure your multimeter leads are securely connected and you're tapping into the correct wire.

If everything is set up properly and there's still no voltage pattern, then we need to check if the sensor is getting its required 8 Volts from the PCM. Go to: TEST 2: Making Sure The CMP Sensor Is Getting 8 Volts.