TEST 2: Making Sure The CMP Sensor Is Getting 8 Volts

In this section, we're gonna verify that the CMP sensor is receiving power from the fuel injection computer (PCM).

We need to rule out the possibility that the sensor isn't producing a signal because it's not getting the 8 Volts it needs to generate its ON/OFF pulse.

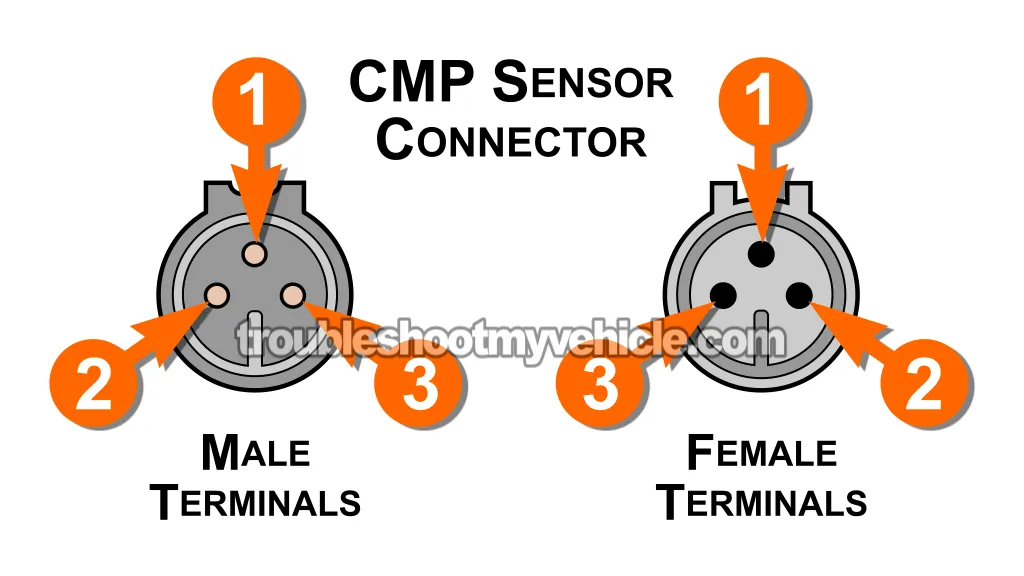

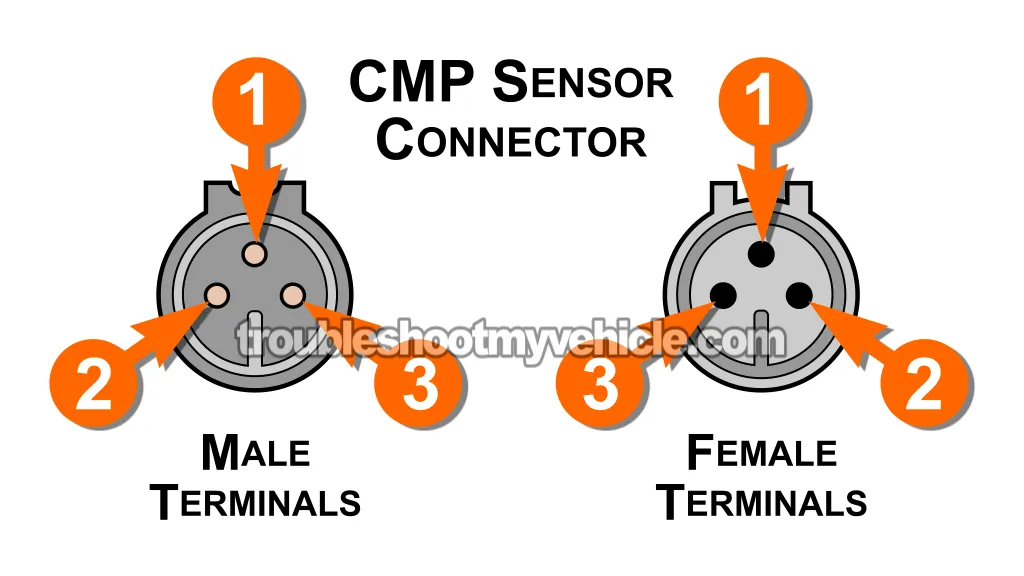

The power supply wire is the orange (ORG) wire connected to terminal #1 on the sensor's 3-wire connector —see the connector pinout diagram above for reference.

We'll use a multimeter to check for voltage with the key in the ON (RUN) position, but without cranking the engine.

Alright, here's the process:

- 1

Unplug the CMP sensor from its connector.

- 2

Connect your multimeter's black lead to the battery's negative (-) terminal.

- 3

Set your multimeter to Volts DC mode.

- 4

Probe terminal #1 with the red multimeter test lead.

NOTE: This test is done on the engine wiring harness connector, which has female terminals. - 5

Have a helper turn the key to the RUN position —but don't crank the engine.

- 6

You should see a reading between 7 to 8 Volts DC.

Let's figure out what your test result means:

CASE 1: CMP sensor is getting power (7–8 Volts). Perfect —this means the camshaft position sensor is receiving the correct voltage from the computer.

Go ahead and continue to the next and last test: TEST 3: Making Sure The CMP Sensor Is Getting Ground.

CASE 2: No power at the sensor. Double-check all your test connections.

If your multimeter still doesn't show 7 to 8 Volts, it's not the sensor that's the problem. Most likely, the issue is an open-circuit problem in the ORG wire between the sensor and the PCM.

Your next step is resolve this missing voltage supply to resolve the CMP sensor DTC.

TEST 3: Making Sure The CMP Sensor Is Getting Ground

At this point in your CMP sensor troubleshooting process, you've confirmed that:

- The CMP sensor isn't outputting its ON/OFF voltage signal (TEST 1).

- It's receiving the voltage it needs from the PCM (TEST 2).

The next step is to check if the CMP sensor is getting a solid Ground connection.

The wire that provides Ground is the black with light blue stripe (BLK/LT BLU) wire on the connector.

The BLK/LT BLU wire connects to female terminal #2 —see the connector pinout diagram above for reference.

IMPORTANT: You've got to be careful here —don't connect this wire to battery positive (+), or you'll fry the PCM. The multimeter voltage check described in the test steps is a safe way to confirm that Ground is present on the CMP connector's Ground wire.

Let's get this show on the road:

- 1

Unplug the CMP sensor.

- 2

Connect the multimeter red lead on the battery's positive (+) terminal.

- 3

Set your multimeter's dial to Volts DC mode.

- 4

Probe the terminal marked #2 with the black multimeter test lead.

Terminal #2 should correspond to the BLK/LT BLU wire.

NOTE: This test is done on the engine wiring harness connector, which has female terminals. - 5

Turn the key to RUN but don't crank the engine.

- 6

Your multimeter should show battery voltage (around 10–12 Volts DC).

Let's interpret that multimeter reading:

CASE 1: Multimeter shows 10 to 12 Volts DC. This confirms the CMP sensor has a good Ground path from the BLK/LT BLU wire.

You can conclude the CMP sensor is bad and needs to be replaced if you've verified:

- The CMP sensor failed to produce an ON/OFF voltage signal (TEST 1).

- The CMP sensor is getting power (TEST 2).

- It's getting Ground (this test section).

NOTE: If you're installing a new sensor, see: Installing The CMP Sensor: Air Gap Clearance.

CASE 2: Multimeter shows no voltage. Double-check your meter connections and retest.

If the 10 to 12 Volts still doesn't show up on your multimeter's display, the BLK/LT BLU wire is no longer delivering Ground.

Without this Ground, the CMP sensor can't operate. This usually points to an open-circuit in the wire between the sensor's connector and the fuel injection computer.

Your next step is resolve this missing Ground supply to resolve the CMP sensor DTC.

Installing The CMP Sensor: Air Gap Clearance

When installing a new CMP sensor on your 1994–1997 3.3L Dodge Caravan, you'll notice a paper spacer attached to its tip.

This spacer is designed to set the correct air gap —approximately 0.020 inches (0.5 mm)— between the sensor and the camshaft gear.

It's imperative to leave this spacer in place during installation; it'll naturally wear away as the engine operates, leaving the sensor at the optimal distance.

Resist the temptation to remove it —doing so could result in the sensor sitting too close to the cam gear, which will damage the sensor when you crank the engine.

In cases where the spacer is missing, like when removing and reinstalling the same sensor (the spacer is always gone), you can fabricate one yourself.

Cut small circles from index cards and glue them together to reach the required thickness. This DIY spacer works just as well as the factory one and creates the clearance you need to tighten the CMP sensor bolt properly.

Replacement paper spacers are also available online if you'd rather not make your own. You can buy it here:

- Walker Products 235-1378 CMP Sensor Spacer (at: amazon.com).

More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials

You can find a complete list of 3.3L V6 Chrysler, Dodge, and Plymouth minivan tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- P0171 Diagnostics (1996-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- P0420 Diagnostics -Catalytic Converter Tests (1996-2010 3.3L V6 Chrysler, Dodge And Plymouth Minivan).

- How To Check For Vacuum Leaks: Carb Cleaner Spray (1991-2010 3.9L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test For A Blown Head Gasket (1991-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

If this info saved the day, buy me a beer!