Testing the throttle body temp sensor on the 1989–1991 3.9L V6 Dodge Ram pickup isn't hard. In this 'how to' tutorial, I'm gonna show you exactly how to test it and figure out if it's good or if it's bad.

You just need a multimeter for the two resistance tests we're gonna cover. Once you run these two quick tests, you'll know if the TB temp sensor's doing its job —or if it's cooked.

Contents of this tutorial:

- Symptoms Of A Bad Throttle Body Temperature Sensor.

- What Does The Throttle Body Temperature Sensor Do?

- Important Initial Checks.

- Where To Buy The TB Temp Sensor And Connector.

- TEST 1: Cold Temperature Resistance Check.

- TEST 2: Hot Temperature Resistance Check.

- More 3.9L V6 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 150 Pickup 3.9L V6: 1989, 1990, 1991.

- Dodge Ram 250 Pickup 3.9L V6: 1989, 1990, 1991.

Symptoms Of A Bad Throttle Body Temperature Sensor

If the throttle body temp sensor fails, it's gonna trigger the check engine light and store this trouble code:

- Code 23: Throttle Body Temp Sensor Voltage Too Low or Too High.

But that's just the start —it also messes with engine performance, especially when you try restarting the engine after it's already warm.

Here's what you'll usually see when the sensor starts acting up:

- Hard start: Engine struggles to start after a short stop —like filling up at the gas station or making a quick store run.

- Rough idle: Engine shakes or idles unevenly after a warm restart.

- Engine stall: Shuts down right after restarting when when the engine's hot.

- Surging or hesitation: You feel the engine lag when you step on the gas after a warm start.

- Extended engine cranking: You've got to crank the engine longer than usual before it starts when the it's been shut off hot.

You'll probably notice the engine starts up fine first thing in the morning, but acts weird when the engine's hot —or after it's been running for a while. That's a clear sign the sensor's sending the wrong temp signal to the computer.

When the sensor fails, it confuses the fuel injection computer (Single Board Engine Controller —SBEC). It might tell the computer the throttle body's ice cold when it's actually hot —or the other way around. That throws off the air/fuel mixture, especially during warm starts, where fuel vapor builds up and makes getting the engine started a challenge.

What Does the Throttle Body Temperature Sensor Do?

The TB temp sensor bolts directly onto the throttle body. Its main job is to keep track of how hot the throttle body gets once the engine's been running. That info really matters when you shut the engine down and try to restart it shortly after.

Right after shutdown, heat rises and gets soaked up by the throttle body. That extra heat raises the fuel temperature, making it vaporize faster —which can lead to hard starts, a rough idle, or even stalling when you crank and start it back up.

The fuel injection computer relies on this sensor to deliver the right amount of fuel. If the throttle body's hot, the computer commands the fuel injectors to inject more fuel —so the engine restarts without sputtering.

This sensor also plays a backup role. Since the system doesn't have a separate intake air temperature sensor, the computer uses the throttle body temp reading as a stand-in to help it figure out the air temp and keep the air/fuel ratio on point.

Important Initial Checks

Before you remove and resistance test the throttle body temp sensor, take a minute to perform these quick visual checks:

- Look over the sensor's wiring harness for any damage —frayed wires, cracked insulation, or any spots where the insulation's missing.

- Check the connector closely. Is it damaged/broken? Make sure that little U-shaped metal retaining clip (lock clip) is still clipped in tight.

- Give the sensor itself a once-over. The upper part's plastic and can crack or snap off the metal base if it's ever been bumped or installed with the wrong tool.

Missing Metal Locking Clip: On these older V6 Dodge pickups, the TB temp sensor connector uses a metal clip to secure it in place —just like the ones you'll see on the fuel injector connectors from the same era.

If that clip's gone or the connector's broken, it might not stay securely connected and making solid contact with the sensor pins. That's a problem —especially with all the heat and vibration under the hood— and it can cause an intermittent false connection.

If that's the case, don't hesitate to swap it out for a new pigtail connector. They're cheap and easy to replace. A solid choice is the WALKER PRODUCTS 270-1034.

Frayed Wires: Fraying happens when the wire's insulation wears out and the copper strands underneath start showing. Super common on these older pickups with aging wiring harnesses.

Those exposed wires can short out or mess with the signal —and that'll lead to incorrect temp readings and lit up check engine light.

Check out this real-world example to see what it looks like:

- IAT Sensor Wire Insulation Problem And Wires Shorted Together (at: easyautodiagnostics.com).

Here's what to do depending on the damage:

- If the wires are seriously frayed or the damage is right near the plug, it's time to replace the whole connector.

- If it's just a small damaged spot further down the line, wrap it up with electrical tape. It's a quick fix that'll hold for a while.

NOTE: Electrical tape's just a temporary patch. If you want the wiring to hold up long-term, go ahead and replace anything that's damaged —whether it's the connector, the wire, or both.

Where To Buy The TB Temp Sensor And Connector

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Cold Temperature Resistance Check

Alright, let's kick things off by pulling the throttle body temp sensor out of the throttle body so we can run a resistance test with a multimeter.

If the sensor's bad, you'll usually get one of these two readings:

- Open circuit: The multimeter will flash "OL" (infinite resistance). That means there's a break inside the sensor —no continuity at all.

- Short circuit: You'll see "0 Ohms" on the screen, which means the sensor's shorted internally from pin to pin.

IMPORTANT: For this test to tell you anything useful, the sensor has to be at room temp. If the engine's been running, give the sensor time to cool all the way down first.

NOTE: Need a multimeter or thinking about upgrading? Here's the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Let's get going:

- 1

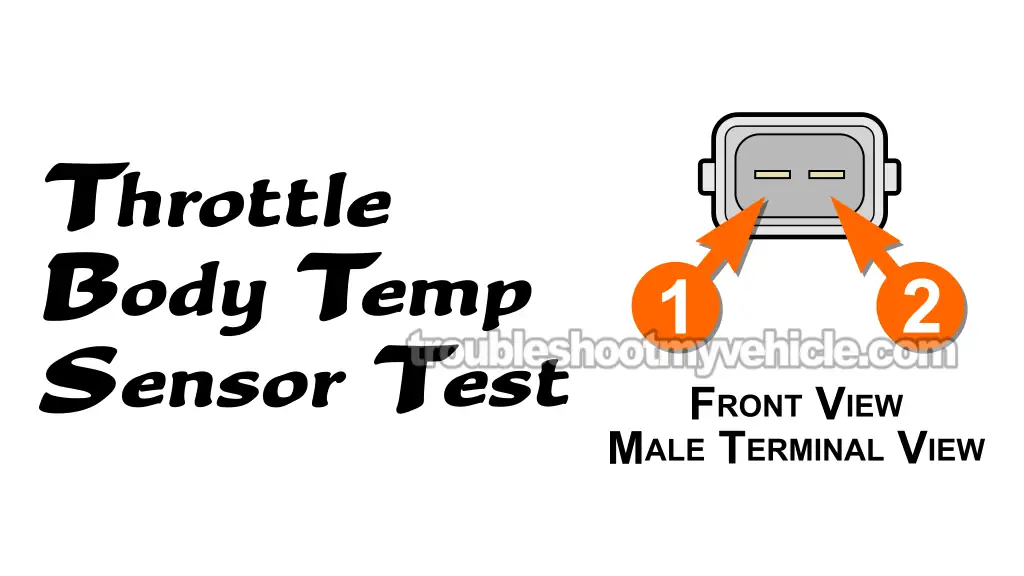

Disconnect the TB temp sensor from its 2-wire plug.

NOTE: Take a good look at the connector —check if it's cracked or missing that U-shaped metal clip that keeps it locked in. - 2

Carefully remove the TB temp sensor from the throttle body.

NOTE: Watch out —the plastic top can snap off pretty easily if you're not careful. - 3

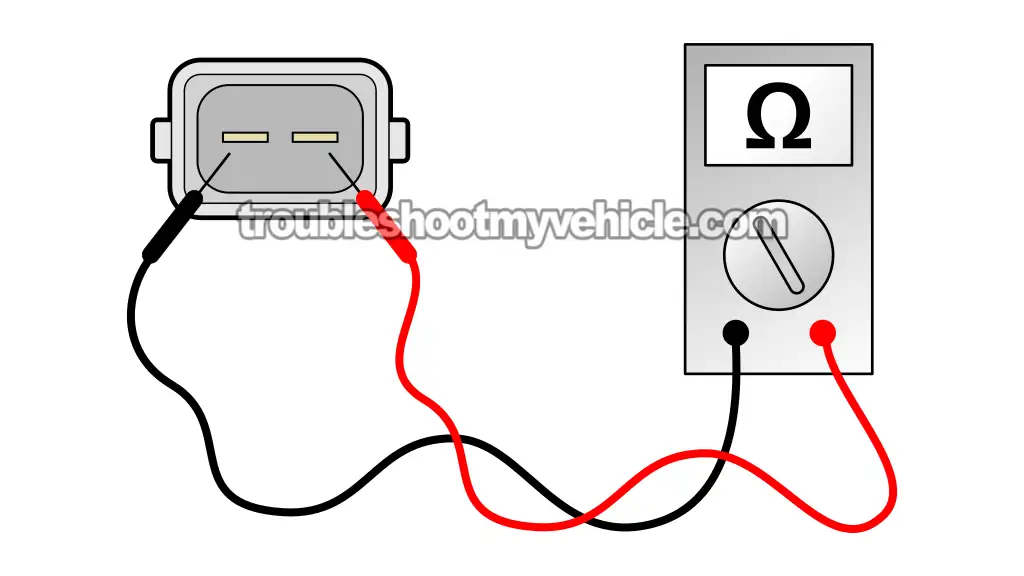

Set your multimeter to measure Ohms (Ω).

- 4

Check the sensor's resistance by touching the multimeter leads to both male terminals.

At room temp, you should get a reading somewhere between 5.6 and 14.6 K Ohms.

Alright, now let's break down what those results mean:

CASE 1: Multimeter shows 0 Ohms. That tells you the sensor's shorted inside —time to replace it.

CASE 2: Multimeter flashes OL (infinite resistance). That means there's no connection inside —the sensor's shot and needs to go.

CASE 3: Resistance is outside the normal range. That usually means the sensor's gone bad.

You can run one more test to confirm before replacing it. Go to: TEST 2: Hot Temperature Resistance Check.

CASE 4: Resistance is within spec. If you're seeing a value inside the expected range, your TB temp sensor is doing its job.

You can run one more test to confirm it's good. Go to: TEST 2: Hot Temperature Resistance Check.