If you're seeing a MAP sensor trouble code (DTC) and your van's engine is running pretty bad, there's a solid chance the sensor's gone bad.

Still, that MAP code can pop up because of an engine issue that's got nothing to do with the sensor itself.

Here's the good part: checking the MAP sensor on your V8 Dodge Ram van is actually pretty easy. You just need a multimeter and a vacuum pump —no scan tool needed. In this tutorial, I'll show you exactly how to test it, step by step.

Contents of this tutorial:

- Symptoms Of A Bad MAP Sensor.

- How The MAP Sensor Works.

- Where To Buy The MAP Sensor And Save.

- TEST 1: Verifying The MAP Signal.

- TEST 2: Making Sure That The MAP Sensor Is Getting Power.

- TEST 3: Verifying The MAP Sensor Ground Circuit.

- MAP Sensor Code Won't Go Away.

- More 5.2L, 5.9L V8 Dodge Ram Van Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram B150 Van 5.2L V8: 1991.

- Dodge Ram B250 Van 5.2L V8: 1991.

- Dodge Ram B250 Van 5.9L V8: 1991.

- Dodge Ram B350 Van 5.9L V8: 1991.

OTHER MAP SENSOR TESTS:

- How To Test The MAP Sensor (1989-1990 5.2L, 5.9L V Dodge Ram Van).

- How To Test The MAP Sensor (1992-1997 5.2L, 5.9L V8 Dodge Ram Van).

- How To Test The MAP Sensor (1998-2003 5.2L, 5.9L V8 Dodge Ram Van).

Symptoms Of A Bad MAP Sensor

When the MAP sensor fails, the check engine light kicks on —triggered by one of these two codes:

- Code 13: MAP Sensor Signal Issue.

- Code 14: MAP Sensor Voltage Is Either Too Low Or Too High.

Besides a MAP sensor diagnostic trouble code (DTC), you're also gonna notice one or more of these problems:

- Rough idle: The engine shakes or idles unevenly when the van's in Drive and you're stopped —like waiting at a red light.

- Black smoke: While the engine's running (especially when you hit the gas), black smoke blows out the tailpipe.

- Sudden engine stalls: It might stall out of nowhere —either while you're coasting or when you step on the gas.

- Immediate stalls after starting: It cranks up, then stalls right after starting.

- Lack of power: The van feels weak when you try to speed up —slow, sluggish, no punch.

- Limp-In Mode: The computer throws the engine into "limp-in" mode to protect it. You'll notice it for sure —power drops way down and gas mileage takes a hit.

NOTE: Crazy as it sounds, other engine problems can trick the computer into thinking the MAP sensor's fried. So don't go replacing it just yet. You gotta test it first to make sure it's really the one causing the trouble.

In this tutorial, I'll show you how to figure out if the MAP sensor's the real issue. We're gonna run a quick bench test —and if it checks out, that tells you the problem's somewhere else.

How The MAP Sensor Works

Your Dodge Ram van doesn't use a mass airflow (MAF) sensor to measure incoming air. Instead, it runs a Speed Density system to figure that out.

Here's how it works —the fuel injection computer keeps an eye on three key signals:

- The manifold absolute pressure —provided by the MAP sensor.

- The intake air temperature —from the IAT sensor.

- Engine speed (RPM), which comes from the distributor pickup coil.

With that info, the computer figures out how much air the engine's pulling in —then calculates exactly how much fuel to inject.

Here's what happens when you crank and start the engine:

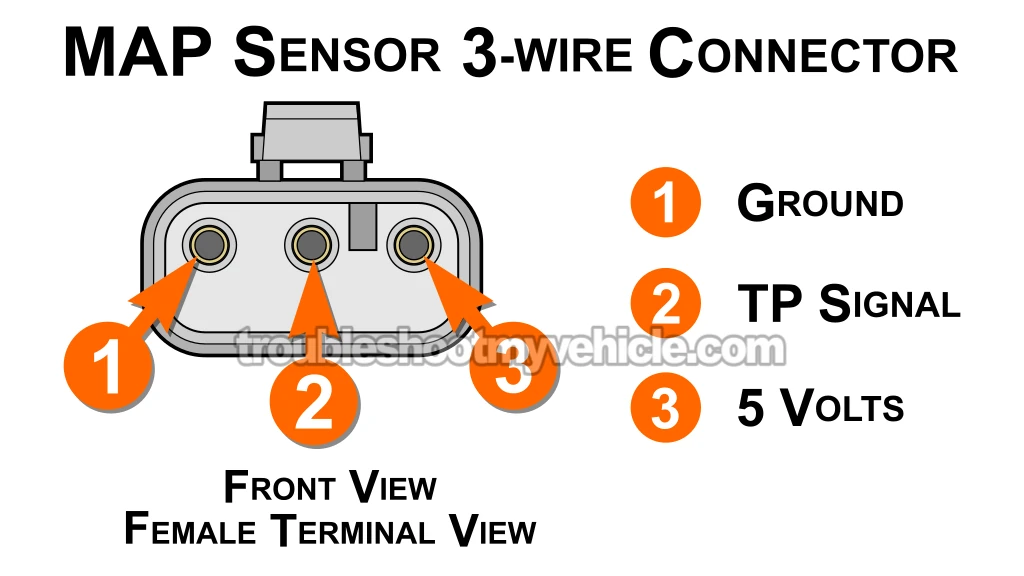

- MAP sensor activation: First, the computer powers up the MAP sensor by sending it voltage and Ground:

- The violet with white stripe (VIO/WHT) wire gives it 5 Volts DC. That's terminal 3 (see image above).

- The black with light blue stripe (BLK/LT BLU) wire provides Ground. It connects to terminal 1.

- Vacuum pressure monitoring: The MAP sensor starts picking up vacuum pressure from the intake manifold.

- Idle RPM: At idle, the engine creates strong vacuum inside the intake manifold, resulting in lower air pressure. In this state, the MAP sensor sends out a relatively low voltage signal to the engine control unit.

- Engine Acceleration: When you press the gas pedal and the engine speeds up, the vacuum inside the intake manifold decreases and pressure increases. As a result, the MAP sensor outputs a higher voltage signal to reflect this change in pressure.

- Fuel injection control: Then the computer uses data from the MAP, IAT, and CKP sensors to:

- Adjust the fuel injector pulse width —basically how long the injectors spray fuel.

- Tweak ignition timing to get the engine running smooth and strong.

Alright —now that you've got the basics, let's get into the actual test.

Where To Buy The MAP Sensor And Save

You can find a MAP sensor for your Dodge Ram van at almost any auto parts store –but you're probably gonna pay way more for it.

My advice is to shop around online, or at the very least, compare prices. That way, you'll get a good idea of how much money you could save. Here are my recommendations:

Not sure if the above MAP sensor fits your particular Dodge Ram van? Don't worry, once you get to the site, they'll make sure it fits by asking you the particulars of your vehicle. If it doesn't fit, they'll find you the right one.

TEST 1: Verifying The MAP Signal

Let's get to it. First thing we need to do is check if your MAP sensor sends out a changing voltage signal when you apply vacuum to it.

You'll hook up a multimeter to the MAP sensor's signal wire, then use a vacuum pump to create vacuum. Don't sweat it if you don't have a pump —your mouth works just fine to pull vacuum.

Here's what you'll see:

- Good Sensor: The voltage will drop and rise as you apply and release vacuum. That's what it's supposed to do.

- Bad Sensor: If it's toast, the voltage won't budge. It stays stuck no matter how much vacuum you apply.

NOTE: If you need to buy a multimeter (or upgrade yours) or a vacuum pump, these are the ones I have and use:

- Multimeter: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

- Vacuum pump: HTOMT 2 In 1 Vacuum Pump Test Set (at: amazon.com).

Alright, here's what to do:

- 1

Pull the vacuum hose off the MAP sensor.

NOTE: Leave the MAP sensor mounted on the throttle body. No need to remove it. - 2

Hook your vacuum pump to the MAP sensor's vacuum port.

IMPORTANT: Keep the sensor plugged into its 3-wire connector. - 3

Attach the black lead of your multimeter to the negative (-) battery post.

- 4

Set your multimeter to DC Volts mode.

- 5

Now connect the red lead to the dark green with red stripe (DK GRN/RED) wire.

That wire's the middle one on the MAP sensor's connector.

NOTE: You can use a back probe or a wire-piercing tool here. For help with that, check out Wire Piercing Probe. - 6

Turn the key to ON, but don't start the engine.

- 7

You should see about 4.5 Volts DC with the key ON and no vacuum applied yet.

- 8

Now apply vacuum to the MAP sensor —use a pump or your mouth. Watch the voltage drop like this:

1.) 0 in. Hg ...... 4.7 Volts

2.) 5 in. Hg ...... 3.9 Volts

3.) 10 in. Hg .... 3.0 Volts

4.) 20 in. Hg .... 1.1 Volts

NOTE: Whether you're using a pump or your lungs, the voltage should go down as you add vacuum and rise again when you let it go.

Now let's break down what your results mean.

CASE 1: The voltage changed when you applied vacuum. Your MAP sensor's working like it should!

If you're still getting a MAP code and the check engine light's on, check out: MAP Sensor Code Won't Go Away.

CASE 2: The voltage stayed stuck at the same number. Most of the time, that means the MAP sensor's no good.

But to be sure, you've gotta check that it's actually getting power and Ground. Start here: TEST 2: Making Sure the MAP Sensor is Getting Power.

CASE 3: You got 0 Volts DC. That means the sensor is either dead or it's not getting power or Ground at all.

Next step: test for power and Ground. Go to: TEST 2: Making Sure That The MAP Sensor Is Getting Power.

TEST 2: Making Sure That The MAP Sensor Is Getting Power

Alright, so you've already confirmed that your MAP sensor isn't sending out a changing voltage —the reading stays flat no matter how much vacuum you give it. Now let's find out if it's getting power, because without it, the sensor can't do anything.

The MAP sensor gets its power from the fuel injection computer. It sends out 5 Volts DC through the violet with white stripe (VIO/WHT) wire.

The VIO/WHT wire hooks up to the terminal labeled number 3 in the diagram of the MAP sensor's connector above.

Here's how to test it:

- 1

Unplug the MAP sensor from its electrical connector.

- 2

Clip the black lead from your multimeter to the negative (-) terminal on the battery.

- 3

Switch your multimeter to Volts DC.

- 4

Turn the key to the ON position —but don't start the engine.

- 5

Use the red multimeter lead to probe the terminal marked number 3.

NOTE: Check that's the one connected to the VIO/WHT wire. - 6

The multimeter should read 4.5 to 5 Volts DC.

Let's break down what that reading means:

CASE 1: You saw 5 Volts on the meter. That means the sensor is definitely getting power.

Next step: make sure it's got a good Ground too. Go here: TEST 3: Verifying The MAP Sensor Ground Circuit.

CASE 2: You didn't see 4.5 to 5 Volts. Double-check your setup and test it again.

If it still shows 0, now you know why the sensor isn't giving out that variable voltage —it's not getting the power it needs.

So in this case, the MAP sensor itself isn't the issue. You'll need to track down and fix the missing 5 Volt supply. Here's what usually causes it:

- A break or problem in the 5 Volt power wire between the MAP sensor and the fuel injection computer.

- Less common —a failure inside the computer itself.