P0420 is one of those codes that usually means what it says —the catalytic converter isn't doing its job anymore.

In my experience, when this code shows up on a 5.2L or 5.9L V8 Dodge Ram pickup, the converter is often the root cause. But to be absolutely sure —and avoid replacing a part unnecessarily —it's worth running a few simple tests to confirm it.

In this tutorial, I'll walk you through how to do exactly that, using tools and techniques any home mechanic can handle.

Contents of this tutorial:

- Symptoms Of A Bad Catalytic Converter.

- Why Catalytic Converters Fail.

- TEST 1: Checking For A Broken Catalytic Converter.

- TEST 2: Checking The Performance Of The Rear Oxygen Sensor.

- TEST 3: Manually Inducing A Lean Air/Fuel Mixture.

- TEST 4: Manually Inducing A Rich Air/Fuel Mixture.

- What "Rich" And "Lean" Mean On An Oxygen Sensor.

- What "Closed Loop" Means —And Why It Matters.

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 1500 Pickup 5.2L V8: 1996, 1997, 1998, 1999, 2000, 2001.

- Dodge Ram 2500 Pickup 5.2L V8: 1996, 1997, 1998.

- Dodge Ram 1500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

- Dodge Ram 2500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002.

- Dodge Ram 3500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

Symptoms Of A Bad Catalytic Converter

When the catalytic converter starts to fail on your Dodge Ram pickup, the signs can range from subtle to severe.

Whether it's broken into pieces (and clogging the exhaust pipe), or simply no longer doing its job, a failing converter affects both performance and emissions. Below are the most common symptoms:

- Check engine light with code P0420: This is the most direct clue —P0420 means the PCM is seeing low catalytic efficiency based on oxygen sensor readings.

- When this code is stored, it's a 99.99% chance your catalytic converter is toast. Yep, it's a bad news code.

- Loss of power under load: A converter whose filter element has broken into pieces can partially clog the exhaust pipe and create backpressure, choking off exhaust flow and killing power —especially when accelerating or towing.

- Poor fuel economy: When exhaust flow is restricted or combustion is affected, gas mileage takes a hit.

- Rattling noise from under the truck: If the internal ceramic filtering element breaks apart, it can rattle, especially at startup or when revving the engine.

- Strong sulfur or rotten egg smell: A failing cat can cause a noticeable smell, especially when the engine is hot or under load.

- Overheating of the converter: In severe cases, a failing and overwhelmed converter can glow red-hot, posing a fire hazard and further engine damage.

Keep in mind, some of these symptoms can also be caused by upstream problems —like misfires, oil burning, a blown head gasket or a bad oxygen sensor —that damage the converter over time.

That's why it's important to test, not guess —and that's exactly what the rest of this tutorial will walk you through.

Why Catalytic Converters Fail

Catalytic converters are built to last, but they're not bulletproof. When one fails —especially on a Dodge Ram pickup with a 5.2L or 5.9L V8— it's almost always the result of another underlying problem that damaged the converter over time.

Here are the most common causes of catalytic converter failure:

- Unresolved misfires: Raw fuel entering the exhaust from a misfiring cylinder can overheat and destroy the converter's internal substrate.

- Oil or coolant burning: Worn piston rings, valve seals, or a blown head gasket can cause oil or coolant to enter the combustion chamber, contaminating and coating the converter's internal surfaces.

- Leaky fuel injectors: Too much fuel in the system can create an overly rich mixture, which leads to excess heat and unburned hydrocarbons reaching the converter.

- Bad oxygen sensors or a faulty thermostat: These components can cause the engine to run rich or too cool, both of which affect combustion and lead to converter failure over time.

- Physical impact: Off-road use, bottoming out, or rough driving conditions can crack the converter's shell or break the ceramic core inside.

It's important to understand that replacing the catalytic converter without fixing the root cause is a short-term fix.

The new converter will eventually fail the same way. That's why proper diagnosis is key —and why this tutorial walks you through testing both the converter and the systems that affect it.

TEST 1: Checking For A Broken Catalytic Converter

One of the most common types of catalytic converter failures is when the internal ceramic core breaks apart.

When this happens, pieces of the substrate can rattle around inside the converter shell —especially when the engine is idling or under load.

In this first test, you'll check for that kind of damage using nothing more than your hand or a rubber mallet.

IMPORTANT: Perform this test with the engine completely cold to avoid burns or injury.

SAFETY WARNING: If you're lifting your vehicle with a jack, always support it with jack stands on solid Ground before crawling underneath. Never trust a jack alone —it's not worth the risk.

Let's get started:

- 1

Make sure the engine is completely cold.

This test is hands-on, and you'll be touching parts of the catalytic converter —so the engine and cat must be cool to the touch. - 2

Safely lift the vehicle (if needed) and install jack stands.

Only raise the truck if the catalytic converter isn't easily reachable from the side. Use wheel chocks, lift it securely, and support it with jack stands. - 3

Locate the catalytic converter.

On the 5.2L and 5.9L Dodge Ram pickup, it's mounted along the exhaust, usually between the Y-pipe and the muffler. - 4

Firmly strike the converter with your palm or a rubber mallet.

If you're using a rubber mallet, don't hit it hard enough to dent the housing —just enough to shake the inside. - 5

Listen for a rattling or metallic clunking sound.

Move to different points along the converter and repeat the process if needed.

CASE 1: You hear a rattling sound when tapping the converter. This usually means the internal ceramic substrate is cracked or broken into pieces.

The converter is compromised —and loose fragments can eventually block exhaust flow, causing power loss or a no-start condition.

CASE 2: You hear no unusual noise when tapping That's a good sign —at least in terms of physical integrity.

The converter is still structurally intact. If you're still getting a P0420 code, you'll want to continue to: TEST 2: Checking The Performance Of The Rear Oxygen Sensor.

TEST 2: Checking The Performance Of The Rear Oxygen Sensor

The rear oxygen sensor (the one located behind the catalytic converter) is responsible for monitoring the converter's efficiency.

When the catalytic converter is working properly, the rear O2 sensor will reflect that by switching back and forth between rich and lean —just like the front O2 sensor.

If the cat is no longer scrubbing exhaust gases effectively, this sensor should show a fairly steady, rich signal —usually at or way above 0.5 Volts.

This test helps you determine if the rear sensor is seeing a fluctuating signal (as it should) or a constantly rich output that may indicate a worn-out converter.

By the way, I'm gonna be tossing around terms like "lean", "rich", and "closed loop". The following sections explain more about these:

NOTE: This is the first of three tests that work together to confirm the rear O2 sensor is functioning correctly —and that it can reliably "accuse" the catalytic converter when it's no longer doing its job.

IMPORTANT: This test should be done with the engine fully warmed up and idling in closed loop. You'll need to use a scan tool with "live data" capability to see the rear O2 sensor's output.

Don't have a scan tool? Need a scan tool? Check out my recommendation: ZM301 OBD2 Scanner Diagnostic Tool (at: amazon.com).

These are the test steps:

- 1

Start the engine and allow it to reach full operating temperature.

The key here is to make sure the PCM goes into closed loop operation (you can use your scan tool to confirm this). - 2

Connect your scan tool to the diagnostic link connector and enter its "live data" functionality.

- 3

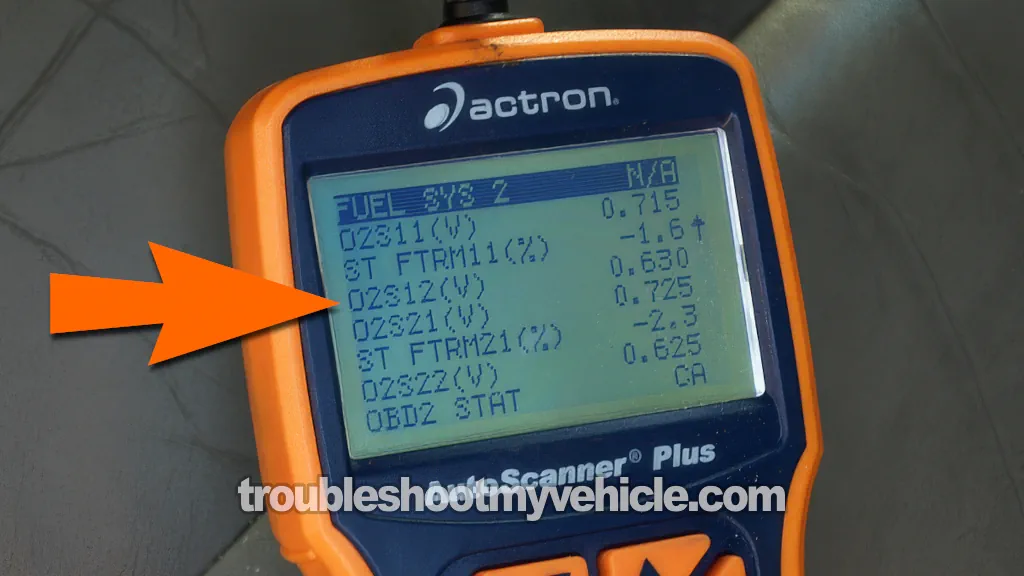

Once in "live data" mode, find the Paramater ID (PID) labeled O2S12.

NOTE: The downstream O2 sensor is generally labeled as O2S12. - 4

Observe the voltage signal from the rear O2 sensor (O2S12).

You're checking to see if it switches back and forth between rich and lean (just like the front sensor), or if it's stuck steadily at or above 0.5 Volts. - 5

Let the engine continue idling and monitor the sensor behavior closely.

A properly functioning catalytic converter will cause the rear O2 sensor's voltage output to to fluctuate between lean and rich just like the front one, while a failing converter won't filter the exhaust effectively —causing the rear sensor to output a relatively steady value above 0.5 Volts.

Let's interpret your test result:

CASE 1: The rear O2 sensor signal stays steady at or above 0.5 Volts. This suggests one of two things:

- Bad catalytic converter: Exhaust gases are passing through unprocessed, and the rear O2 sensor is picking that up and confirming it. The converter is failing —or has already failed— and its performance is degraded.

- Bad rear O2 sensor: The sensor itself may be faulty and not accurately reporting what’s happening in the exhaust stream.

To figure out which one it is, we need to test the sensor’s response. Head over to: TEST 3: Manually Inducing A Lean Air/Fuel Mixture.

CASE 2: The rear O2 sensor switches between rich and lean, just like the front sensor. This is a good sign —it means the catalytic converter is currently scrubbing hydrocarbons effectively.

If you're still getting a P0420 code, the converter may be in the early stages of failure, struggling under high load but still performing at idle.