TEST 3: Checking For A Short To Ground In The Output Shaft Speed Sensor Wiring

In this test, we're going to check both wires of the output shaft speed sensor circuit for a short to Ground.

As you're already aware, the output shaft speed sensor has two wires:

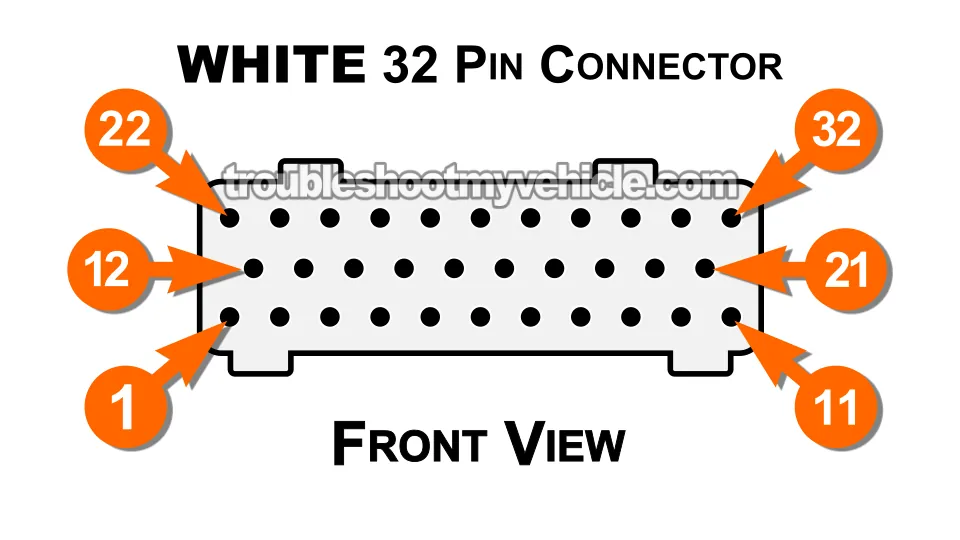

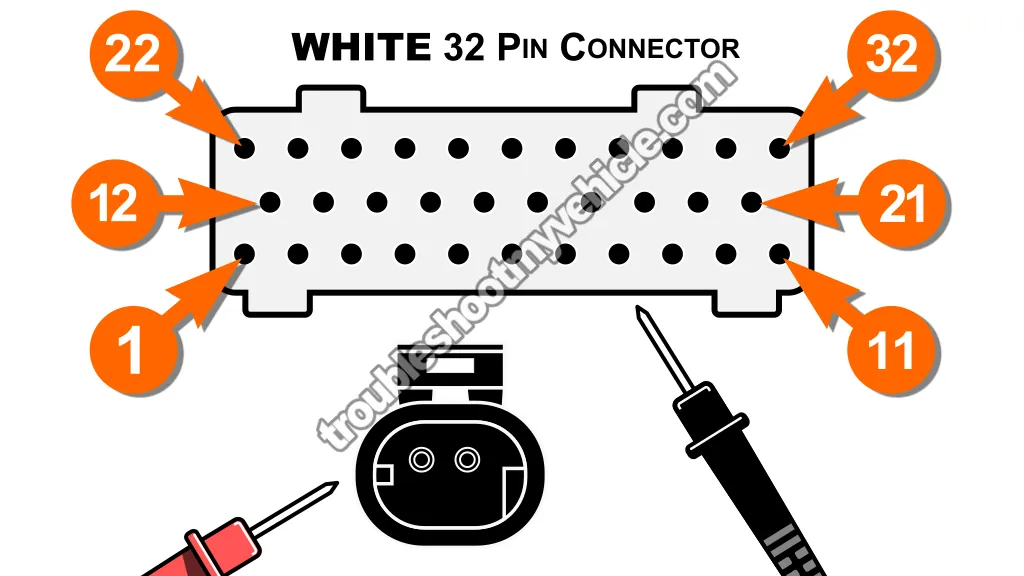

- Dark blue with black stripe (DK BLU/BLK): It connects to pin 25 of the WHITE PCM connector.

- Light green with white stripe (LT GRN/WHT): Connects to pin 28 of the WHITE PCM connector.

These wires should be electrically isolated from Ground. If either wire's insulation is damaged —exposing the copper inside and allowing it to touch metal parts like the transmission case, a bracket, or the frame —the PCM will detect a fault and trigger a P0720 code.

We'll check for this by measuring resistance from each wire to chassis Ground with the PCM and battery disconnected.

We'll also perform a wiggle test on the harness to help uncover any intermittent faults that only show up with vibration or movement —just like what happens when you're driving.

IMPORTANT: Do not insert your multimeter test leads directly into the PCM terminals —doing so will deform or damage them. For a safe probing method, see: How To Safely Probe The PCM Connector -Without Damaging It.

These are the test steps:

- 1

Set your multimeter to Ohms (Ω) mode.

- 2

Disconnect the battery's negative (–) cable from it's post.

- 3

Disconnect all 3 PCM connectors.

We'll be working with the WHITE connector. - 4

Disconnect the output shaft speed sensor from its connector on the transmission case.

- 5

Probe pin 25 of the WHITE PCM connector with one multimeter lead.

CAUTION: Use a thin probe that won't damage the female terminal. - 6

Touch the other multimeter lead to chassis Ground.

You can use the battery negative cable terminal or a clean, rust-free bolt on the engine or frame. - 7

You should see infinite resistance (open-circuit) or "OL", confirming there is no short to Ground in the DK BLU/BLK wire.

- 8

Repeat the test for pin 28 (LT GRN/WHT wire) in the same manner. It should also show infinite resistance or "OL".

- 9

Reconnect the output shaft speed sensor and repeat the test for both wires again. This checks for any Ground fault inside the sensor itself.

- 10

Have a helper gently wiggle the transmission connector and the wiring harness leading up to the PCM.

Watch the multimeter for any flicker or sudden change in resistance, which could indicate an intermittent short to Ground that only occurs with movement or vibration.

Let's interpret your test result:

CASE 1: One or both wires show continuity to Ground (low resistance) at any point during the test. This indicates a direct short to Ground —usually due to the wire rubbing against metal and exposing the copper strands.

Visually inspect the harness for signs of chafing, melting, or damage near brackets, the transmission, or the firewall. Repairing the affected section should solve the P0720 issue.

This tutorial offers some repair ideas:

CASE 2: Resistance is "OL" at first, but drops or flickers during the wiggle test. This suggests an intermittent short to Ground, most likely from a damaged or loose wire that only Grounds out during movement.

Carefully inspect and flex the harness along its entire visible length, especially where it bends or touches hard surfaces. Repairing the damaged section will solve the P0720 issue.

This tutorial offers some repair ideas:

CASE 3: Both wires show open-circuit ("OL") throughout the test —including during the wiggle step. This confirms neither wire is shorted to Ground.

Up to this point, you've confirmed:

- The resistance of the OSS sensor is within specification (TEST 1).

- The entire output shaft speed sensor circuit is OK (TEST 2).

- The OSS sensor wires are not shorted to Ground (this test section).

If DTC P0720 keeps coming back, it starting to look like the PCM is bad. See: Is The PCM Bad?

TEST 4: Checking Wire Integrity (Sensor To PCM)

In this test, we're going to check the continuity and overall integrity of both wires that connect the output shaft speed sensor to the PCM. Specifically:

Specifically, we'll check the dark blue with black stripe (DK BLU/BLK) wire and the light green with white stripe (LT GRN/WHT) wire between the PCM connector and OSS sensor connector.

This test will allows us to detect if an open circuit problem exists in either wire.

NOTE: Rather than using the continuity (beep) function on the multimeter, we'll use Ohms mode for a more accurate measurement.

IMPORTANT: Do not insert your multimeter test leads directly into the PCM terminals —doing so will deform or damage them. For a safe probing method, see: How To Safely Probe The PCM Connector -Without Damaging It.

OK, let's get started:

- 1

Set your multimeter to Ohms (Ω) mode.

- 2

Disconnect the battery negative (–) cable.

- 3

Disconnect all three PCM connectors.

NOTE: We'll be working with the WHITE PCM connector. - 4

Disconnect the output shaft speed sensor from its harness connector.

- 5

Probe pin 25 of the WHITE PCM connector (DK BLU/BLK wire) with one multimeter lead.

CAUTION: Use a thin, non-damaging probe to avoid spreading the terminal. - 6

Touch the other multimeter lead to the female terminal of the DK BLU/BLK wire at the output shaft speed sensor connector.

CAUTION: Use a thin, non-damaging probe to avoid spreading the terminal. - 7

The multimeter should show less than 1 Ohm of resistance.

- 8

Now test pin 28 of the WHITE PCM connector (LT GRN/WHT wire) the same way.

One test lead at pin 28, the other at the female terminal (of the OSS sensor connector) that connects to the LT GRN/WHT wire. - 9

The multimeter should also be below 1 Ohm of resistance.

Let's interpret your test result:

CASE 1: One or both wires show infinite resistance (OL). This indicates an open-circuit —the wire is broken somewhere along its length, possibly from damage, corrosion, or a disconnected terminal.

Inspect and repair or replace the affected wire to resolve the P0720 DTC problem. This tutorial may be of help:

CASE 2: Both wires show less than 1 Ohm of resistance. This confirms both wires are intact from end to end with no opens or excessive resistance.

Up to this point, you've confirmed:

- The resistance of the OSS sensor is within specification (TEST 1).

- Multimeter shows open-circuit ("OL") or infinite resistance for the entire OSS sensor circuit (TEST 2).

- The OSS sensor wires are OK (this test section).

That leaves you with a bit of a dilemma —since TEST 2 pointed to an open-circuit issue, but now the wires appear fine. This suggests you're likely dealing with an intermittent open, where the connection comes and goes depending on conditions like vibration, movement, or temperature.

At this point, it's a good idea to repeat TEST 1 and wiggle the harness during the measurement to see if the resistance reading changes. If it does, you've found your intermittent issue.

Is The PCM Bad?

A bad PCM causing a P0720 and transmission shift issues is rare —but not impossible. If you've confirmed all of the following:

- The output shaft speed sensor is working correctly.

- The wiring has no opens or shorts.

- The OSS sensor connector is in good shape.

- The sensor signal is reaching the PCM.

...and the code still comes back, then a faulty PCM could be the culprit.

The PCM uses internal circuitry to read the sensor signal. If that circuit is damaged, it won't interpret the sensor input correctly and may trigger a persistent P0720.

This type of failure can be caused by things like a voltage spike from a bad alternator, improper jump-starting, or internal component aging.

That said, don't point the finger at the PCM too quickly —it should be the last thing on your list, after all electrical tests and sensor checks have passed.

I've personally never seen a PCM failure cause trouble code P0720, but it's not impossible.

If you're truly at the end of the line with your diagnostics, consider either having your PCM bench-tested by a reputable PCM repair shop, or temporarily installing a known-good PCM on your pickup.

Just be aware that even a used PCM must be flashed with your vehicle's VIN to load the correct software —so swapping one in just to see if the problem goes away doesn't always work unless it's properly programmed.

More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials

I've written several more tutorials for the V8 Dodge Ram pickups that may be of interest to you that you can find in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Fuel Pump (1992-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test The MAP Sensor -P0107, P0108 (1997-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test Engine Compression (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- Troubleshooting A Blown Head Gasket (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

If this info saved the day, buy me a beer!