Code P0753 means the PCM isn't seeing the expected response from the 3-4 shift solenoid —also known as the overdrive solenoid.

On the 1996–2003 Dodge Ram with a 5.2L or 5.9L V8 with a 46RE transmission, this usually points to a wiring fault or failed solenoid —not always a bad transmission.

In this step-by-step tutorial, I'll walk you through how to test the solenoid, its wiring, and PCM control —without removing the transmission pan.

With just a multimeter and a bit of patience, you'll get to the bottom of the problem confidently and safely.

NOTE: Throughout this tutorial, I'm gonna be using the terms 3-4 shift solenoid and overdrive solenoid interchangeably —they refer to the exact same solenoid.

Contents of this tutorial:

- What Does DTC P0753 Mean?

- Symptoms Of A Bad 3-4 Shift Solenoid.

- What Does The 3-4 Shift Solenoid Do?

- Common Reasons Why Code P0753 Gets Triggered.

- TEST BASICS: Use Ohms Mode, Not Continuity.

- TEST 1: Checking Resistance Of The 3-4 Shift Solenoid (No Pan Removal Required).

- TEST 2: Making Sure The 3-4 Shift Solenoid Is Getting Power.

- TEST 3: Checking The 3-4 Shift Solenoid Control Circuit For A Short To Ground.

- TEST 4: Checking For Shorts Between Solenoid Control Circuits.

- Common Problems With The 8-Wire Transmission Connector.

- What If The PCM Is Bad?

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 1500 Pickup 5.2L V8: 1996, 1997, 1998, 1999, 2000, 2001.

- Dodge Ram 2500 Pickup 5.2L V8: 1996, 1997, 1998.

- Dodge Ram 1500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

- Dodge Ram 2500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002.

- Dodge Ram 3500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

What Does DTC P0753 Mean?

Diagnostic trouble code (DTC) P0753: Transmission 3-4 Shift Solenoid / Transmission Relay Circuits is an OBD-II trouble code indicating an electrical problem with overdrive solenoid circuit.

In a nutshell, this is usually caused by one of the following:

- An open or short in the 3-4 shift solenoid's wiring.

- A loss of power to the solenoid.

- A failed overdrive solenoid.

In the next section —Common Reasons Why Code P0753 Gets Triggered— I'll break down exactly why the overdrive solenoid tends to fail.

Symptoms Of A Bad 3-4 Shift Solenoid

Common symptoms of P0753 you're gonna see on your V8 Dodge Ram pickup include:

- Check Engine Light: The CEL will turn on and store the P0753 code.

- Limp Mode: The transmission may default to 3rd gear, skipping 1st and never shifting into overdrive.

- This causes sluggish takeoff, high RPMs at highway speeds, and a loss of fuel economy.

- No Overdrive: The transmission won't shift into 4th gear, keeping the engine in a lower gear range even at cruising speed.

- Hard or erratic shifting: Shifts may be rough, delayed, or unpredictable —especially when moving into 1st or 4th gear. If the circuit is intermittent, symptoms may come and go.

- Reduced acceleration: Starting in 3rd gear severely limits torque and power off the line, making the truck feel bogged down or unresponsive.

What Does The 3-4 Shift Solenoid Do?

The 3-4 shift solenoid (overdrive solenoid) is an electronic valve inside the transmission that controls fluid pressure to the overdrive clutch pack, allowing the transmission to shift into 4th gear.

In the 46RE transmission, this solenoid is typically part of a combined TCC/OD solenoid assembly mounted on the valve body.

By default (when de-energized), the solenoid vents pressure from the overdrive circuit, keeping the transmission in 3rd gear. When the PCM wants overdrive, it Grounds the solenoid's control wire —energizing the solenoid, closing the vent, and building pressure to apply the overdrive clutch.

In short: the solenoid acts like a small electric valve, controlled by the PCM, that engages or disengages 4th gear by managing fluid flow to the OD clutch.

If the solenoid fails, or if it's not getting the proper command signal, the transmission will stay in 3rd and skip overdrive entirely —especially noticeable at highway speeds.

Common Reasons Why Code P0753 Gets Triggered

In a nutshell, DTC P0753 is almost always caused by one of the following: a failed solenoid, bad wiring, power supply loss, or PCM driver failure.

Here's a more detailed breakdown of these issues:

- Defective 3-4 shift solenoid: The solenoid wears out and its internal winding suffers either an open or short circuit problem.

- Wiring harness fault (open or shorted circuit): The overdrive solenoid control wire between the PCM and solenoid can break (open), short to Ground or power, or corrode at connectors.

- Any of these electrical faults will interrupt proper solenoid operation and cause the PCM to set a P0753 DTC.

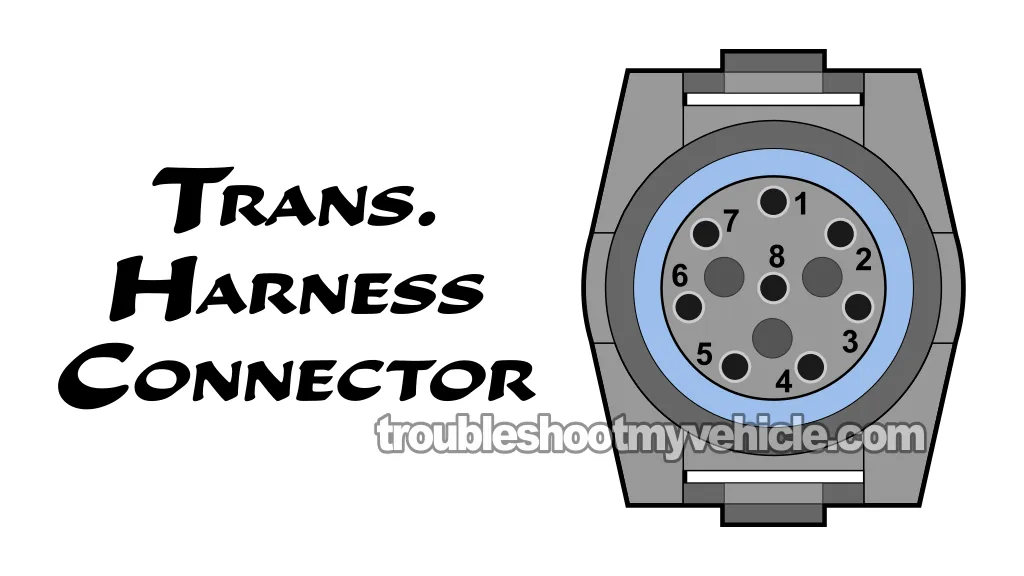

- 8-Pin transmission connector issues: The 8-pin connector that plugs into the transmission case is a common failure point.

- Wires connected to the terminals inside the connector often break off (from their terminals) due to vibration, heat, or age —causing open-circuit or intermittent connection issues.

- This connector fails so frequently that replacement pigtails are widely available at auto parts stores and online.

- Take a look at: Common Problems With The 8-Wire Transmission Connector.

- Transmission power relay or blown fuse: The solenoids get 12V power through the Transmission Relay in the Power Distribution Center.

- If the Transmission Relay or its fuse fails —or loses power due to an unrelated short in the engine wiring harness— P0753 and a few other codes can be triggered together.

- In fact, Chrysler's diagnostic steps tie a related code P1765 to this scenario – P1765 indicates a problem in the trans 12V supply circuit, and if it appears alongside P0753, it means the PCM isn't seeing power to the solenoid.

- Short to Ground or short to voltage: If the solenoid control wire rubs through and touches metal (Ground) or another power wire (12V), the PCM will see the wrong voltage and flag a P0753 DTC.

- Faulty PCM: Rare, but possible. If the PCM's internal driver for the 3-4 solenoid fails, it won't be able to control the solenoid correctly, triggering the code. This is typically only suspected after all other possibilities are ruled out.

NOTE: P0753 is not triggered by mechanical issues like low fluid or valve body sticking. However, dirty fluid can overheat and damage the solenoid over time, so checking fluid condition is always a smart step.

In short, P0753 is almost always caused by one of the following: a failed solenoid, bad wiring, power supply loss, or PCM driver failure.

TEST BASICS: Use Ohms Mode, Not Continuity

When you're checking for shorts between wires or a wire shorted to Ground, always use the Ohms (Ω) setting on your multimeter —not the Continuity setting.

Continuity mode just tells you that there's some between two points, but it won't show you how strong that connection is. It might beep even if there's 30 or 40 Ohms of resistance —which could lead you to a false conclusion.

To get accurate results, especially when hunting for near-zero resistance (like a hard short), you need to see the actual resistance value. In Ohms mode:

- A true short will show 0.1 to 0.5 Ohms.

- Anything above that —especially 5 Ohms or more— may indicate corrosion, damaged wiring, or a different problem entirely.

So for precise diagnostics, stick with Ohms mode when testing for shorts.

TEST 1: Checking Resistance Of The 3-4 Shift Solenoid (No Pan Removal Required)

Before we do any type of check (like checking power or wiring issues), we need to confirm the 3-4 shift solenoid itself isn't open or shorted internally —and that its wiring is intact.

The cool thing is that we can do exactly that, without removing the transmission pan!

We'll measure resistance through the entire solenoid circuit, end to end, using access points in the Power Distribution Box and at the PCM.

To be a bit more specific, we'll test across these two points:

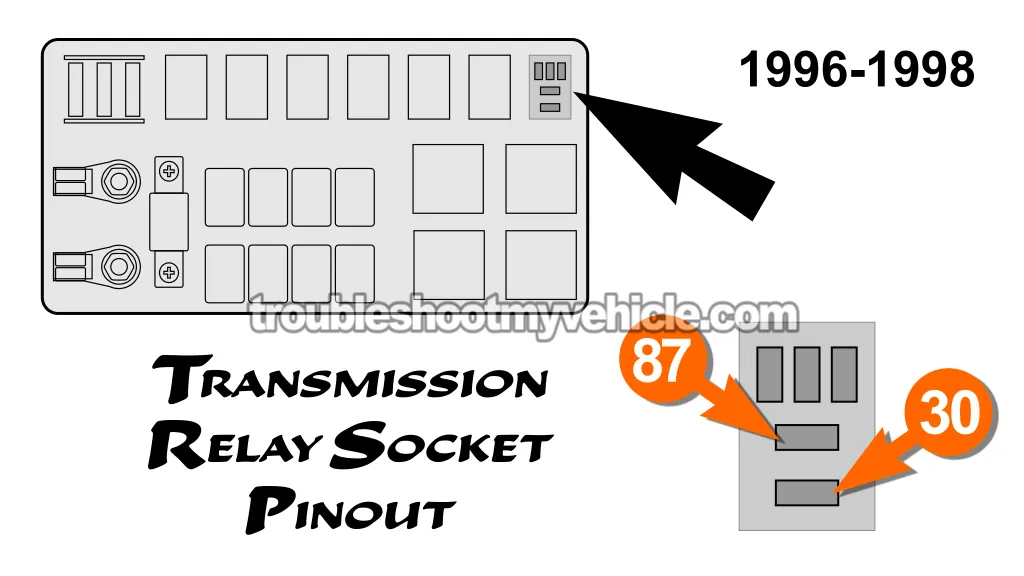

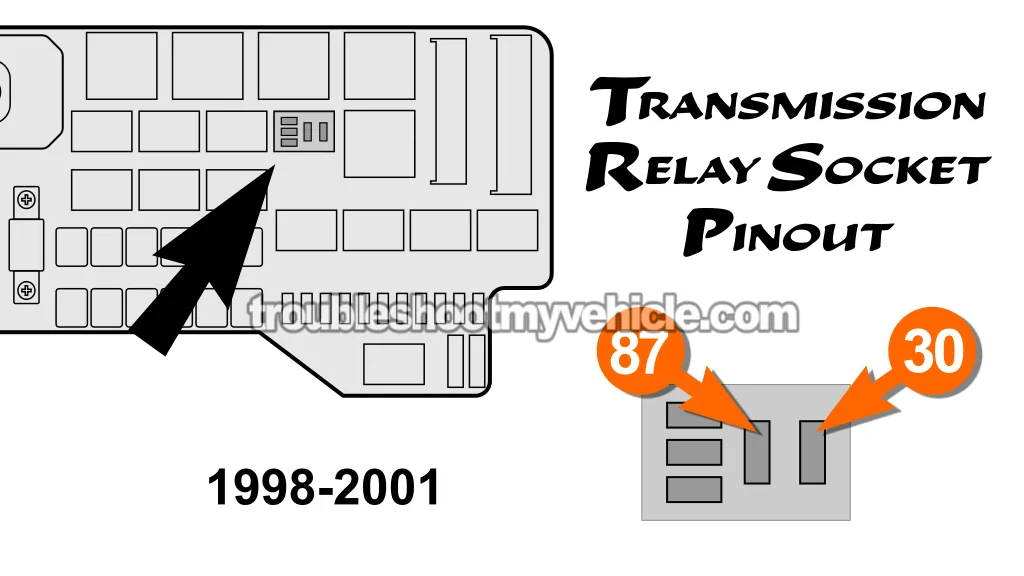

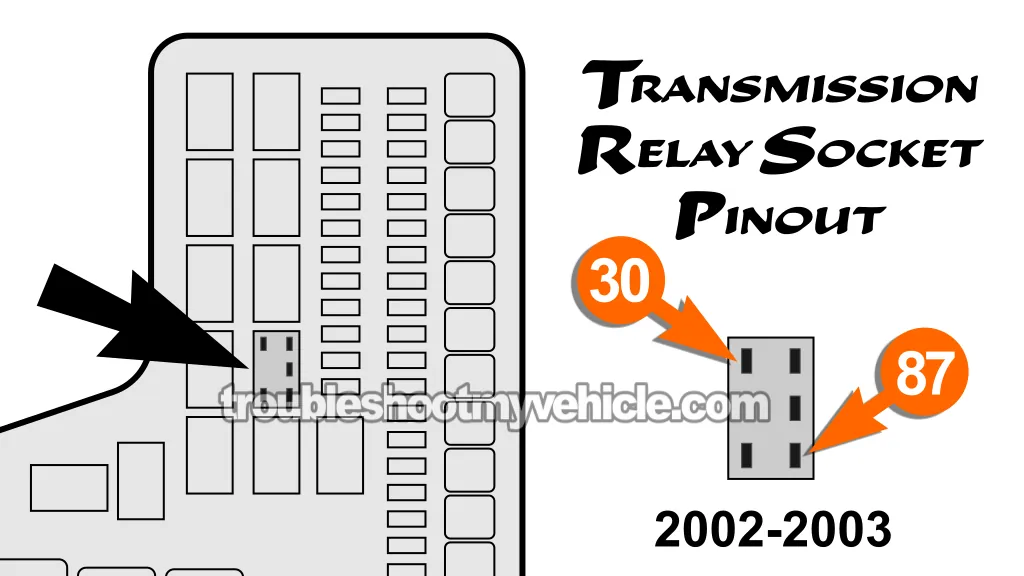

- Transmission Power Relay cavity terminal 87 in the Power Distribution Center.

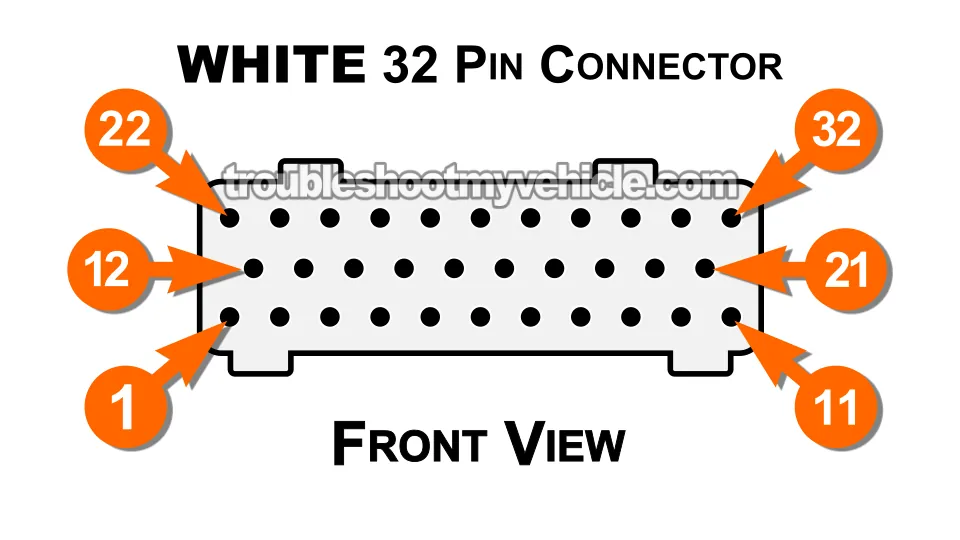

- PCM pin 21 of the WHITE connector (1996-2003 Dodge Ram pickups w/ the 46RE automatic transmission).

IMPORTANT: It's critical that you do not use standard multimeter probes to test between the Transmission Relay socket and pin 21 of the WHITE PCM connector —they're too thick and can damage the terminals in the relay socket or PCM connector. To avoid a costly headache, please review the proper probing techniques I've outlined in the following two tutorials:

- How To Safely Probe The PCM Connector -Without Damaging It (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Safely Probe A Relay Socket Without Damaging The Terminal.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Alright, let's get started:

- 1

Disconnect the battery negative (-) cable from its post.

- 2

Remove the Transmission Power Relay from the Power Distribution Center (underhood fuse/relay box).

- 3

Disconnect all three PCM connectors.

- 4

Locate female terminal 87 of the Transmission Relay socket on the Power Distribution Center.

Female terminal 87 connects and feeds the output power of the relay to the 3-4 shift solenoid. - 5

Set your multimeter to Ohms mode (Ω).

- 6

Connect one multimeter lead to terminal 87 in the relay socket.

You can use a small probe or back-probing wire lead. - 7

Connect the other multimeter lead to pin 21 of the WHITE PCM connector.

NOTE: The PCM has three connectors: BLACK, WHITE, and GREY. Make sure you're testing at terminal 21 on the WHITE connector. - 8

Observe the resistance reading on the multimeter. A good 3-4 shift solenoid circuit should show between 26 and 40 Ohms.

- 9

Have a helper gently wiggle the transmission connector and the wires coming out of it.

NOTE: Be sure to wiggle not just the connector itself, but also the wires running from it—as far as possible into the harness. Wiggle any visible or accessible sections of the wiring harness as well. This is a critical part of the test and should not be skipped, as it'll reveal hidden intermittent faults that only show up under vehicle vibration or movement. - 10

The resistance reading should remain steady during the wiggle test.

If the Ohms reading flickers or glitches out, there's a wiring or connector issue causing intermittent contact.

Let's interpret your test result:

CASE 1: Resistance reading is between 26 and 40 Ohms and remains steady during wiggle test. The solenoid and its wiring are in good condition.

Move on to: TEST 2: Making Sure The 3-4 Shift Solenoid Is Getting Power.

CASE 2: Resistance is out of spec (too high, too low, or infinite). This may indicate a faulty solenoid, open wire, shorted coil, or internal damage in the wiring harness.

Go to: TEST 3: Checking The 3-4 Shift Solenoid Control Circuit For A Short To Ground.

CASE 3: Resistance is in spec at first but flickers or drops during wiggle test. This suggests an intermittent connection.

The most likely causes are:

- A section of the wiring harness has chafed against a sharp metal surface, damaging or removing the insulation from several wires. This allows exposed copper strands to short to Ground or to each other.

- One or more female terminals inside the 8-wire transmission connector may have separated from their wires and make intermittent contact as the connector is moved or wiggled.

Inspect the wiring harness closely for signs of rubbing, cuts, or broken terminals, and repair any damage before moving on. See:

TEST 2: Making Sure The 3-4 Shift Solenoid Is Getting Power

The 3-4 shift solenoid gets 12 Volts from the Transmission Relay, located in the Power Distribution Center (underhood fuse/relay box).

The wire that delivers power to the overdrive solenoid is the red (RED) wire of the transmission's 8-pin harness connector.

This same RED wire delivers power to the Torque Converter Clutch (TCC) solenoid and the Variable Force (Pressure Control) Solenoid inside the transmission.

IMPORTANT: This test must be done with the engine and transmission completely cold to avoid burns. If you need to lift the vehicle, always use jack stands —never rely on the jack alone!

CAUTION: Before unplugging the 8-wire transmission case connector, it's a good idea to spray compressed air (if you have an air compressor) —and if needed, a small amount of brake cleaner— around the connector to remove dirt or debris that could fall into the terminals.

Brake cleaner is flammable, so only perform this cleaning step with the engine and transmission completely cold, and make sure there are no ignition sources nearby. Always allow the area to dry completely before continuing with electrical testing.

Alright, this is what needs to be done:

- 1

Reconnect the PCM to its 3 connectors.

- 2

Reconnect the battery negative (-) cable to its post.

- 3

Disconnect the 8-wire transmission electrical connector at the transmission case.

- 4

Connect the black multimeter test lead to chassis Ground.

My preferred method is to use a jumper wire to connect it directly to the battery negative (-) terminal. - 5

Set your multimeter to Volts DC mode.

- 6

Probe terminal 1 of the 8-wire connector with the red multimeter test lead.

Terminal 1 should correspond to the red (RED) wire of the 8-wire connector. - 7

Turn the key ON —engine OFF (KOEO) and check for battery voltage (10 to 12 Volts).

- 8

Now start the engine (KOER) and repeat the voltage check. Power should still be present with the engine running.

- 9

Turn off the engine and reconnect the 8-wire connector back to the transmission.

Let's interpret your test result:

CASE 1: You see 10-12 Volts with the key ON and with the engine running. This confirms the Transmission Power Relay is functioning and the 3-4 shift solenoid is receiving power.

You can conclude that, at this point, the overdrive solenoid is likely OK —since you've already confirmed its internal and circuit resistance is within 25 to 60 Ohms (TEST 1), and it's receiving proper power in this test.

If code P0753 keeps coming back, it may indicate an intermittent issue —often caused by a damaged wire in the engine wiring harness that only fails under certain driving conditions.

I recommend visually inspecting the wiring harness, starting at the 8-wire transmission case connector and tracing it up into the engine compartment. Look for any section rubbing against sharp edges, brackets, or bolts —anything that could chafe through the insulation and damage the wires inside.

CASE 2: You see no voltage in either condition. This indicates a power supply issue and without it, the overdrive, TCC and Pressure Control solenoids won't work.

Your next step is to check the Transmission Relay, its fuse, and the wiring between the relay and the transmission harness.

A quick way to rule out a bad relay is to swap it with a neighboring relay in the Power Distribution Center —such as the A/C or Horn relay, as long as it's the same type. Then take the vehicle for a short road test.

If the swap solves the issue, problem found.