TEST 3: Making Sure The VSS Sensor Is Getting Power

In this step, we're gonna confirm that the vehicle speed sensor is receiving the power (8 Volts) it needs to operate properly.

Without this 8V input, the sensor won't function —and that alone can trigger a Code 15 (the missing speed signal error code).

This voltage comes directly from the PCM and is delivered through the orange (ORG) wire on the sensor's 3-wire pigtail connector.

To test it, we'll disconnect the sensor and measure the voltage right at the 8V supply terminal inside the connector.

OK, let's check the power supply:

- 1

Switch the ignition to the ON position, but don't start the engine.

This powers up the PCM and energizes the 8V reference circuit. - 2

Disconnect the VSS sensor from its 3-wire harness connector.

- 3

Set your multimeter to measure DC Volts.

- 4

Touch the black multimeter lead to a clean, bare metal spot on the engine or chassis.

NOTE: Make sure the surface is free of rust, paint, or grime to ensure a good Ground connection. - 5

Use the red lead to probe the front of the female terminal that connects to the orange wire.

- 6

Your multimeter should show between 7.5 and 8 Volts.

Let's break down what that result tells us:

CASE 1: Voltage between 7.5 and 8 Volts is present. That's what we want —it means the VSS sensor is getting the power it needs from the PCM.

Next up, let's check if the sensor has a solid Ground connection. Head to: TEST 4: Making Sure The VSS Sensor Is Getting Ground.

CASE 2: No voltage at the orange wire. This usually points to an open in the 8V supply circuit between the PCM and the sensor connector.

In most cases, that means the ORG wire is damaged or broken (open) somewhere between the VSS sensor connector and the PCM connector.

Troubleshooting and fixing this type of issue goes beyond the scope of this tutorial, but it's your next step if voltage is missing.

TEST 4: Making Sure The VSS Sensor Is Getting Ground

In this final test, we're going to verify that the vehicle speed sensor is getting a proper Ground. Without it, the sensor can't generate the ON/OFF signal pulses the PCM depends on.

The Ground for the VSS is supplied directly by the PCM through the black with light blue stripe (BLK/LT BLU) wire at the 3-wire connector.

To check this safely, we'll use a multimeter to measure voltage between the Ground terminal and the 5V power terminal on the connector. If both are present, you've got a complete circuit.

IMPORTANT: This Ground is internal to the PCM. Do not connect this wire to 12V power under any circumstance —doing so will deep fry the PCM. The multimeter voltage check I'm outlining below is a completely safe and non-destructive way to check for Ground.

Let's get started:

- 1

Disconnect the vehicle speed sensor from its 3-wire connector.

- 2

Turn the ignition to the ON position —but don't start the engine.

This powers the PCM and activates the sensor circuits. - 3

Set your multimeter to the DC voltage setting.

- 4

Touch the red test lead into the connector terminal for the orange (ORG) wire —this is your 8V power supply line.

- 5

Touch the black test lead into the terminal for the black/light blue (BLK/LT BLU) wire —this is the sensor's Ground.

- 6

Your multimeter should report a voltage reading between 7.5 and 8 Volts between both terminals, confirming that the PCM is providing Ground.

Let's figure out what your test result means:

CASE 1: Voltage reads between 7.5 and 8 Volts. That's exactly what we want —it confirms the PCM is supplying a solid Ground through the BLK/LT BLU wire.

Next up, let's move to the final check: TEST 5: Inspecting The Plastic Speedometer Pinion Gear.

CASE 2: No voltage detected. This means the Ground circuit is open —most likely from a broken or damaged BLK/LT BLU wire somewhere between the sensor and the PCM.

Pinpointing and repairing this type of wiring fault goes beyond what I'm covering in this tutorial, but it's your next step if Ground is missing.

TEST 5: Inspecting The Plastic Speedometer Pinion Gear

Mounted beneath the Speedometer Drive Gear (SDG) Housing, the speedometer pinion gear is made of plastic and is prone to wear over time.

If this gear becomes worn, stripped, or damaged, it can cause the speedometer to stop working —and also trigger a Code 15.

In this final test, we'll remove both the VSS sensor and the SDG Housing from the transmission or transfer case to visually inspect the gear for damage or wear.

NOTE: The SDG Housing must be aligned correctly with the transmission or transfer case using index marks —one mark on the case, and one on the SDG Housing. The following tutorial is a must read:

Alright, here's what to do:

- 1

Spray down the VSS and SDG Housing area with brake cleaner to clean off any built-up dirt, oil, and road grime covering them.

NOTE: Always wear safety glasses and make sure you're working away from open flames or heat sources. - 2

Let the cleaned area dry out completely before moving to the next step.

- 3

Mark the current alignment using an oil-based marker —one mark on the SDG Housing, and one on the transmission or transfer case.

This reference will make reinstalling the assembly much easier and more accurate. - 4

Remove the bolt and retaining clamp that secure the SDG Housing, then gently pull the unit out of the transmission or transfer case.

- 5

Inspect the plastic speedometer pinion gear for damage.

Check closely for chipped, worn-down, or missing teeth —especially rounded edges or cracks.

NOTE: The gear's tooth count is usually stamped right on the plastic surface.

Let's see what your result is telling us:

CASE 1: The pinion gear is in good condition. That's exactly what you want to see.

If you've confirmed all of the following, then the sensor itself is bad and needs replacement:

- TEST 1: No speed reading appears on your scan tool during the road test.

- TEST 2: No ON/OFF voltage signal at the WHT/ORG wire.

- TEST 3: The 8V supply to the sensor is present.

- TEST 4: A solid Ground connection is confirmed.

- TEST 5: The plastic pinion gear is intact and undamaged.

Don't skip this important section before installing a new sensor:

CASE 2: The pinion gear is damaged or stripped. If the teeth are worn or missing, you've found your problem. Replacing the gear will resolve the signal loss and clear the trouble code.

Be sure to install a replacement gear with the exact same number of teeth as the one you removed. Using the wrong tooth count will throw off your speedometer reading.

After replacing the gear, reinstall the SDG Housing and VSS sensor. Align them using your original marks —or follow the indexing procedure here:

A More Controlled Method for Spinning the Wheels During the VSS Signal Test

If you've ever tried rotating the rear wheels while the truck is idling in Drive with the back end raised on jack stands, you know how tough it is to get them spinning slow enough to catch the voltage pulses from the vehicle speed sensor.

I've been in that exact situation —and trust me, trying to catch those ON/OFF transitions on a multimeter can be frustrating when the wheels are spinning too fast.

Here's a method I've used that gives you better control:

- Turn the ignition key to the ON position —but don't start the engine.

- This powers the VSS and the circuit, so you're ready to test.

- Position your multimeter so you can clearly see it from behind the vehicle, after you've tapped into the sensor's signal wire.

- With your helper turning one rear wheel and you turning the other —both in the same direction— you'll ensure the driveshaft actually rotates.

- Just turning one wheel may not be enough to move the driveshaft —both need to spin to engage the internal transmission output shaft.

Just to clarify: the sensor isn't directly activated by the driveshaft. But if the driveshaft is turning, you know the output shaft inside the transmission is turning —and that's what rotates the plastic pinion gear inside the SDG Housing, which the VSS sensor reads.

This hands-on method takes a little teamwork, but it gives you precise control of rotation speed —which really helps when you're chasing down a stubborn Code 15 and need to verify the sensor's output.

I've used this trick more than once, and I hope it helps you cut through the hassle.

PCM Receives VSS Signal —But the Speedometer Stays At Zero

If you've used an OBD-I scan tool with "live data" functionality to confirm the VSS sensor is outputting a speed signal, but your speedometer needle stays at zero, then the VSS sensor is working —since the PCM is getting the signal.

It looks like the speedometer itself is the problem and it's what is preventing you from seeing your speed as you drive around town in your pickup.

Here's what you need to know: The VSS sends its signal through the white with orange stripe (WHT/ORG) wire. Internally, that wire splits into two paths —one goes to pin 47 of the PCM 60 pin connector, and the other goes straight to the instrument cluster to drive the speedometer.

So, if the scan tool confirms vehicle speed is being read correctly through the VEHICLE SPEED PID, but the speedometer needle doesn't move, the most likely issue is a failure inside the instrument cluster —specifically the speedometer circuit.

To confirm, you can remove the instrument cluster and back-probe the WHT/ORG wire at the connector. Then, slowly spin the rear wheels by hand. If your multimeter picks up pulsing voltage on that wire, the sensor and wiring are fine —and the speedometer itself is the problem.

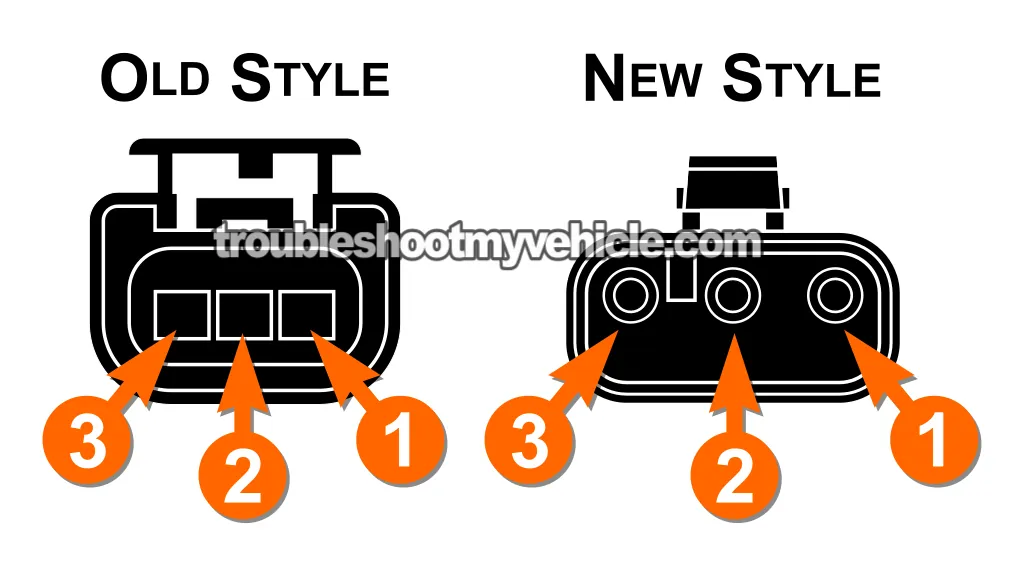

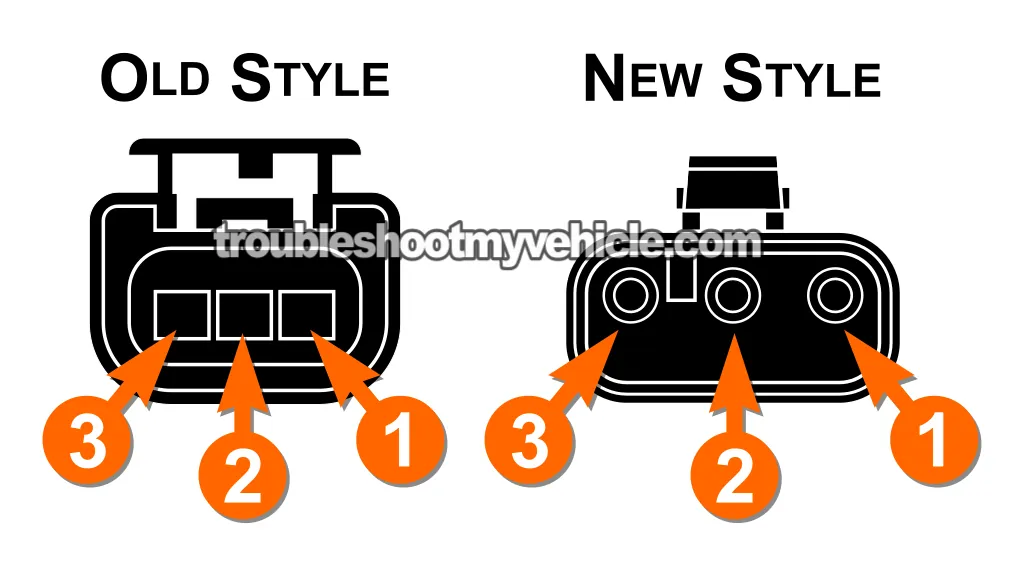

Updated VSS Sensor Connector And Why Soldering Is Critical

At this point, there's a strong chance your Dodge Ram pickup already has the newer-style vehicle speed sensor (VSS) and matching connector. These upgrades have been standard for quite a while, as the original style sensor and connector haven't been available for years.

In the very unlikely event your pickup still has the original setup, you should know that replacement VSS sensors are only sold in the updated design. They usually include a new connector pigtail that must be spliced into your engine's wiring harness.

The one very important thing to know and do is to not install the new pigtail with crimp-on (butt) connectors. While crimp-on connectors may seem convenient, they're prone to loosening over time from vibration, heat cycles, or corrosion. This makes them one of the most common causes of intermittent VSS signal issues that can drive you crazy.

The proper way to install the new connector is to solder the wires and protect the connection with high-quality heat-shrink tubing. This creates a strong, weather- and vibration-resistant repair that won't give you problems later on.

No doubt, soldering them does takes a little extra time, but trust me, it'll save you a lot of frustration down the road, especially since this sensor lives underneath the truck and is constantly exposed to moisture, dirt, and temperature swings.

More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials

I've written several more tutorials for the V8 Dodge Ram pickups that may be of interest to you that you can find in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Fuel Pump (1992-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test The MAP Sensor -P0107, P0108 (1997-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test Engine Compression (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- Troubleshooting A Blown Head Gasket (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

If this info saved the day, buy me a beer!