Testing the pre catalytic converter oxygen sensors on your Ford 3.0L or 3.8L V6 OBD II equipped car, mini-van, or pick up is not that hard.

I'm gonna' show you how to test them so that if you do need to replace one of both, you'll know that you're really replacing a bad part.

Your 3.0L, 3.8L Ford vehicle comes equipped with several oxygen sensors, this article concentrates on testing the ones that are located before the catalytic converter (O2S11 and O2S21).

Contents of this tutorial:

Important Suggestions And Tips

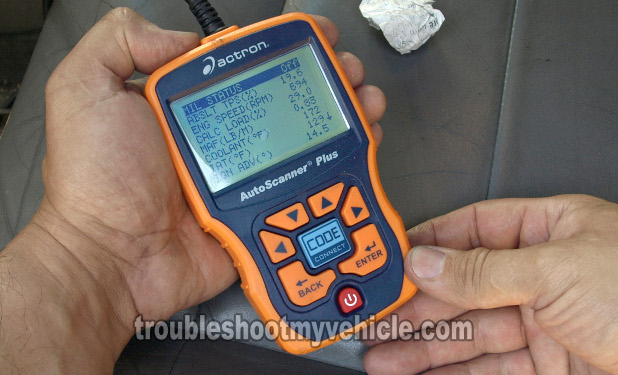

TIP 1: The fastest and easiest way to test the oxygen sensors on your Ford vehicle is with a scan tool that has Live Data capability. You don't need an expensive $2K to $5K (US) Scan Tool to do it. I have written this article so that you can accomplish the O2 sensor tests with a generic scan tool (Don't have a scan tool? Need a scan tool? Check out my recommendation: Actron CP9580 Scan Tool).

TIP 2: You don't have to remove the O2 sensors from your vehicle to test them. The procedure I'm gonna' show you here is an on-car test of the oxygen sensors, no need to remove them.

Oxygen Sensor Basics

I'm gonna' give you a very, very brief explanation of how the O2 sensors work on your Ford 3.0L, 3.8L vehicle. In this short explanation, I'll explain the basics of what you and I need to know to test them and nothing more. If you need a more in-depth technical explanation, you can Google it.

In a nutshell, the job of the pre catalytic converter oxygen sensors is to help the PCM fine tune the amount of fuel it injects into the engine. If too much is injected (known as a Rich condition), the O2 sensors will let it know and the PCM will make the necessary adjustments to inject less. If it doesn't inject enough (known as a Lean condition), they'll make it aware of it and the PCM will inject more.

Here are some more specifics:

- 1

If the PCM is injecting too much fuel into the engine, the oxygen sensor produces a voltage above 0.500 Volts. This voltage can go as high as 0.900 to 1.0 Volt.

With this type of voltage, the PCM considers that the air/fuel mixture as too Rich and starts to inject less. - 2

As the PCM starts to inject less fuel, it may go too far and not inject enough. Here again the O2 sensor saves the day by reporting a voltage that can go as low as 0.050 to 0.100 Volts.

Voltages in this range let the PCM know that the air/fuel mixture is too Lean and starts to inject more. - 3

This process of injecting more or less fuel, by the PCM, goes on the entire time the engine is running (and if the O2 sensor is working correctly).

- 4

The really cool thing is that you can observe these changes using a scan tool in its Live Data mode, and this is how I'm gonna' show you how to test them.

- 5

A correctly working O2 sensor will produce a voltage that will switch between a Lean and Rich condition several times every few seconds. So, if the voltage output of the O2 sensor stays fixed (when testing it), the O2 sensor has failed.