In this tutorial, you'll learn how to check the fuel pump's amperage draw by measuring its internal resistance on your 2005-2008 3.0L V6 Ford Escape or Mercury Mariner.

Why should you care about the fuel pump's amperage draw? Because if it's pulling too much current —even though it might still be running— it's only a matter of time before the fuel pump driver module (FPDM) ends up failing.

By doing this quick and easy test, you'll catch a worn-out, high-current draw fuel pump before it has the chance to wipe out the FPDM module —or ruin the brand-new module you're about to bolt in.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Ford Escape: 2005, 2006, 2007, 2008.

- 3.0L V6 Mercury Mariner: 2005, 2006, 2007, 2008.

- 3.0L V6 Mazda Tribute: 2005, 2006.

MORE FUEL PUMP DIAGNOSTIC RESOURCES: You can find links to the fuel pump pressure test, the FPDM module tests, and the inertia switch tests in this section:

Why Check Fuel Pump Amperage Draw?

One thing that doesn't always get talked about with Ford's returnless fuel system —the one using a fuel pump driver module (FPDM)— is that, just like any other PWM setup controlling the Ground side of a motor (whether it's the fuel pump here or the electric radiator fans in other systems), these modules are extremely sensitive to how much current the component is pulling.

And by sensitive, I mean if the fuel pump is drawing more amps than it should, the FPDM is gonna end up burning out. It's not a maybe —it's just a matter of when.

Even when the fuel pump is still running and showing pressure on the gauge, if it's pulling higher-than-normal current, it's basically acting like a ticking time bomb for the FPDM —and in some cases, it may have already taken the module out.

Here's a more detailed explanation of this issue:

- When the electric motor is new (whether it's a fuel pump or any other component) —and everything inside it is healthy— the current draw is staying low and steady.

- As time goes on, the bushings, bearings, and even the brushes inside the motor begin to wear out. That extra friction adds resistance, and the motor has to pull more current just to keep itself spinning.

- Eventually the motor gives up completely and stops running. But in plenty of cases, it keeps turning while pulling more current than the fuse on its circuit was ever rated for.

- On a regular non-PWM setup, that extra current draw just pops the fuse —and that's the end of it.

- But on a PWM-controlled setup like the one in your Ford Escape or Mercury Mariner, the fuel pump circuit isn't being protected by a fuse in the same way. So when the fuel pump starts drawing too many amps, the FPDM ends up overheating inside and literally deep-fries itself.

- If you ask me, this is hands down the biggest design flaw in the whole system.

I've seen it more than once: the FPDM module is bypassed to check the fuel pump, the pump runs, and the engine fires up. So the FPDM gets called bad and swapped out. Problem solved, right? Not so fast.

The truth is the fuel pump was still running and making pressure, but it was pulling way too much current. The new FPDM module doesn't stand a chance —it's cooked within a day or two. That kind of misdiagnosis happens a lot more often than you'd think.

That's why I always stress checking the pump's internal resistance. You can do it easily with a multimeter, then use Ohm's Law to figure out how much current that pump is actually drawing.

If the math shows the pump is pulling 15 Amps or more, you've found your problem. And better yet, you just saved yourself from burning up another FPDM module down the road.

Checking The Fuel Pump's Internal Resistance

Alright, let's get started with checking the fuel pump's internal resistance and calculating how much current it's really drawing:

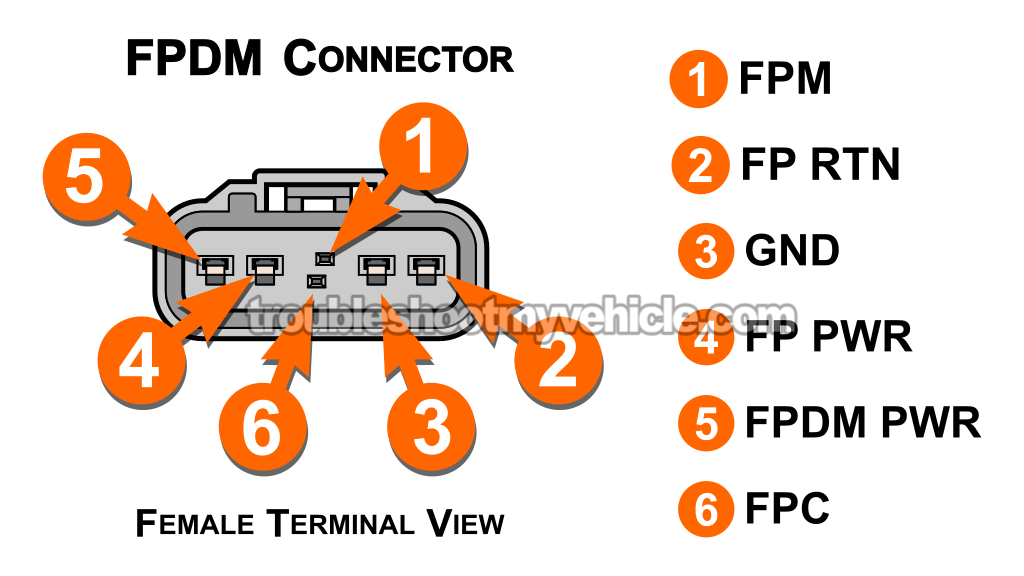

- Begin by disconnecting the fuel pump driver module (FPDM) from its 6-wire connector so you can get direct access to the pump's circuit.

- Set your multimeter to the Ohms (resistance) mode.

- With your red multimeter test lead, gently probe terminal 4 of the FPDM connector.

- Terminal 4 is the wire that connects straight to the positive (+) side of the fuel pump.

- With your black multimeter test lead, make contact with terminal 2 of the FPDM connector.

- Terminal 2 is the wire that connects directly to the negative (–) side of the fuel pump.

- Take a look at the resistance value your meter is displaying and make a note of it. This number is what you'll be using for the amperage calculation.

- Now apply Ohm's Law to figure out the pump's current draw:

- Divide the system's supply voltage (use 12.5 Volts as your base) by the resistance reading you just recorded. The result is the pump's amperage draw.

- For example, if the pump's resistance is showing 0.4 Ohms, the math looks like this: 12.5 ÷ 0.4 = 31.25. That means the pump is drawing 31.25 Amps.

- Compare your result to the spec: the fuel pump's current draw should not be exceeding 15 Amps. Anything higher is telling you the pump is worn out and is on its way to cooking the FPDM.

More Fuel Pump Troubleshooting Help

FUEL PUMP PRESSURE TESTS:

FUEL PUMP INERTIA SWITCH TESTS:

FUEL PUMP DRIVER MODULE (FPDM) TESTS:

- FPDM Basic Operating Theory (2005-2008 3.0L Ford Escape, Mercury Mariner).

- Fuel Pump Driver Module Tests (2005-2008 3.0L V6 Ford Escape, Mercury Mariner).

More 3.0L V6 Ford Escape Diagnostic Tutorials

You can find a complete list of 3.0L V6 Ford Escape, Mercury Mariner, and Mazda Tribute diagnostic tutorials in this index:

Here's a sample of the diagnostic tutorials you'll find in the index:

- How To Test The MAF Sensor (2001-2007 Ford 3.0L V6 Ford Escape).

- How To Test Engine Compression (2001-2012 3.0L V6 Ford Escape).

- How To Test For A Blown Head Gasket (2001-2012 3.0L V6 Ford Escape).

- How To Test The Fuel Pump (2001-2004 3.0L Ford Escape).

If this info saved the day, buy me a beer!