The 2005-2008 3.0L V6 Ford Escape and Mercury Mariner use a returnless fuel system. In this setup, the Fuel Pump Driver Module (FPDM) acts as the middle man between the fuel pump relay and the fuel pump and this module is known to fail quite a bit.

The good news is that testing it isn't difficult, and you can do it without taking the vehicle to the shop. In this tutorial, I'll show you the way I test the FPDM module so you can figure out if it's good or bad.

The FPDM module test is critical any time you've checked fuel pressure and the gauge shows 0 PSI, since zero pressure can be caused by either a bad FPDM module or a bad fuel pump. The FPDM test I'm gonna show you'll help you tell which one is the culprit.

Here's what we're going to check, step by step:

- Make sure the FPDM module is getting power (VPWR) and Ground (PWR GND).

- Check the Fuel Pump Control (FPC) signal.

- Check the Fuel Pump Monitor (FPM) signal.

- Confirm the FPDM module is actually activating the fuel pump.

Let's get started.

Contents of this tutorial:

- Fuel Pump Driver Module Basic Checks.

- Tools Needed To Check The FPDM.

- TEST 1: Checking The FPDM PWR (12 Volts) Circuit.

- TEST 2: Checking The PWR GND (Chassis Ground) Circuit.

- TEST 3: Checking Fuel Pump Activation.

- TEST 4: Checking The Fuel Pump Control (FPC) Signal.

- TEST 5: Checking The Fuel Pump Monitor (FPM) signal.

- Sealing The Wire Punctures After Testing.

- More Fuel Pump Troubleshooting Help.

- More 3.0L V6 Ford Escape Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Ford Escape: 2005, 2006, 2007, 2008.

- 3.0L V6 Mercury Mariner: 2005, 2006, 2007, 2008.

- 3.0L V6 Mazda Tribute: 2005, 2006.

MORE FUEL PUMP DIAGNOSTIC RESOURCES: You can find fuel pump circuit wiring diagrams, related fuel pump tests, and the inertia switch tests in this section:

FPDM OPERATING THEORY: This guide explains how the FPDM works, a must read to wrap your head around how this returnless system works:

Fuel Pump Driver Module Basic Checks

When the fuel pump driver module (FPDM) fails, it usually shows up in one of two ways:

- Either the engine won't start at all because the fuel pump isn't delivering fuel,

- Or the engine will start but run poorly because the module can't properly control the fuel pump and supply the right amount of fuel to keep it running.

Before we jump into testing the FPDM module itself, there are two important checks we need to do first:

CHECK 1 → Scan for Trouble Codes:

Hook up a scan tool that can read Ford's enhanced (manufacturer-specific) codes. What you're looking for are codes that point to problems in the fuel pump control system. The most common ones are:

- P1233: Fuel Pump Driver Module Offline Or Disabled (No communication from PCM).

- P1235: Fuel Pump Control Out Of Range (PCM can't regulate it properly).

- P1237: Fuel Pump Secondary Circuit Fault (often internal to the FPDM module).

If any of these codes show up, that's your first sign the FPDM module isn't working like it should and it's time to test it further.

NOTE: A P0191 (Fuel Rail Pressure Sensor Performance) trouble code can also point to the FPDM module not doing its job, even though the code makes it look like the FRP sensor is at fault.

If you don't see any codes, don't stop here —not every failure sets a code. Move on to CHECK 2.

CHECK 2 → Fuel Pressure Test:

Once you've scanned for FPDM codes, the next step is to check fuel pressure with a gauge. This tells you exactly what the pump is producing, instead of relying only on the FRP sensor reading on the scan tool.

It's a step a lot of people skip, but it's important. Knowing the real fuel pressure lets you separate a FRP sensor issue from a weak or dead fuel pump.

If you haven't run a fuel pressure test yet, here's the tutorial that shows you how:

IMPORTANT: Even though this tutorial focuses on an engine no-start caused by a bad FPDM or fuel pump, the same checks —especially the voltage drop test in TEST 2— can also help diagnose performance issues in the FPDM module circuits.

Tools Needed To Check The FPDM

The key tool you'll need for this job is a multimeter that can read duty cycle %. That's because the PCM controls the FPDM module with a duty cycle % signal, called the FPC signal.

To test the FPDM module, you'll need to measure that FPC command and compare it against the specs in the manual. The module also sends a duty cycle % signal back to the PCM as feedback, so both sides of the circuit depend on it.

Just to be clear, this is not the same as a multimeter that only measures Hertz (Hz). You need one that specifically reads duty cycle %. If you've already got one, you're ready. If not, here's the one I use and recommend:

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

You'll also need a few more things:

- A wire piercing probe.

- These wire piercing probes are the ideal back probe for the FPDM module tests: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

- Battery jump start cable: We'll use a jump start cable to extend the reach of the multimeter test lead to the battery negative (-) post in TEST 2.

TEST 1: Checking The FPDM PWR (12 Volts) Circuit

Our first step in diagnosing the Fuel Pump Driver Module (FPDM) is to make sure it's getting power.

This power comes from the fuel pump fuse, passes through the fuel pump inertia switch, and then reaches the FPDM module. It's only available with the key in the RUN or START position.

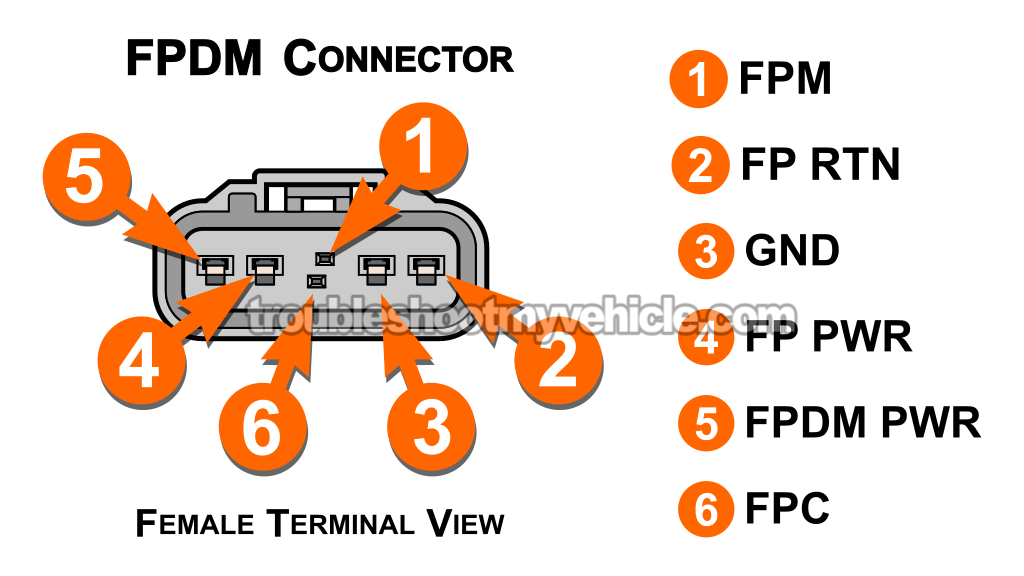

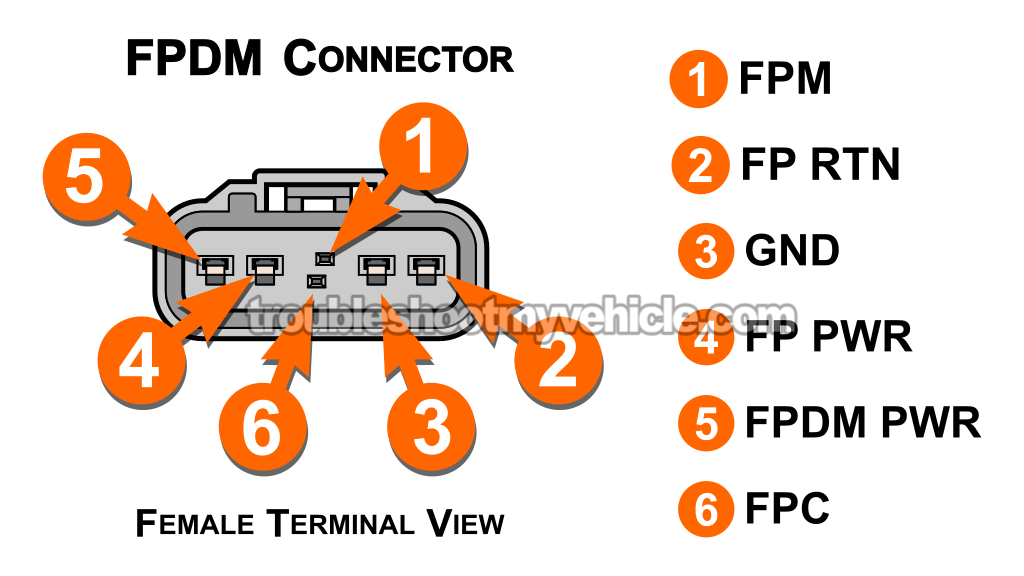

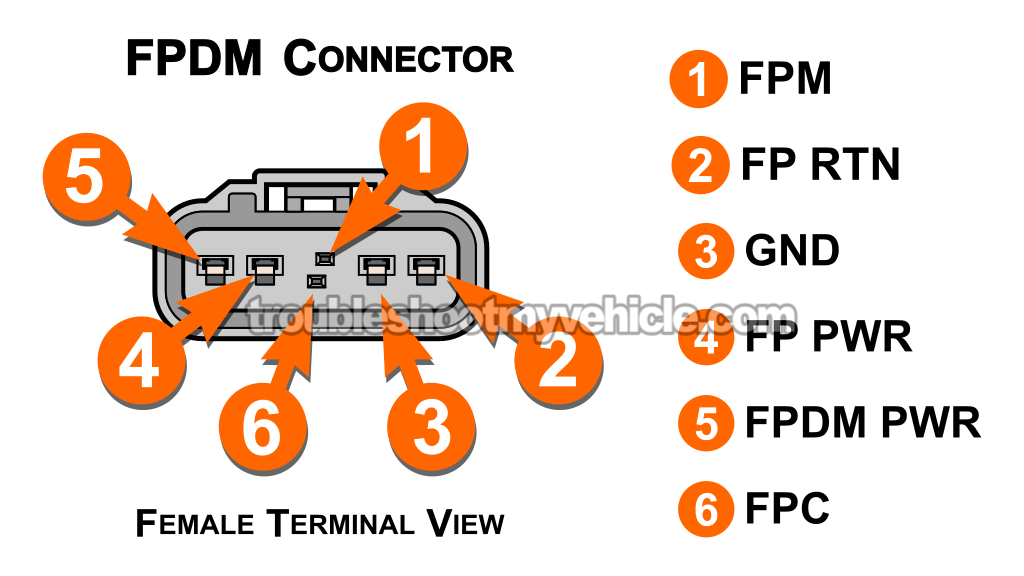

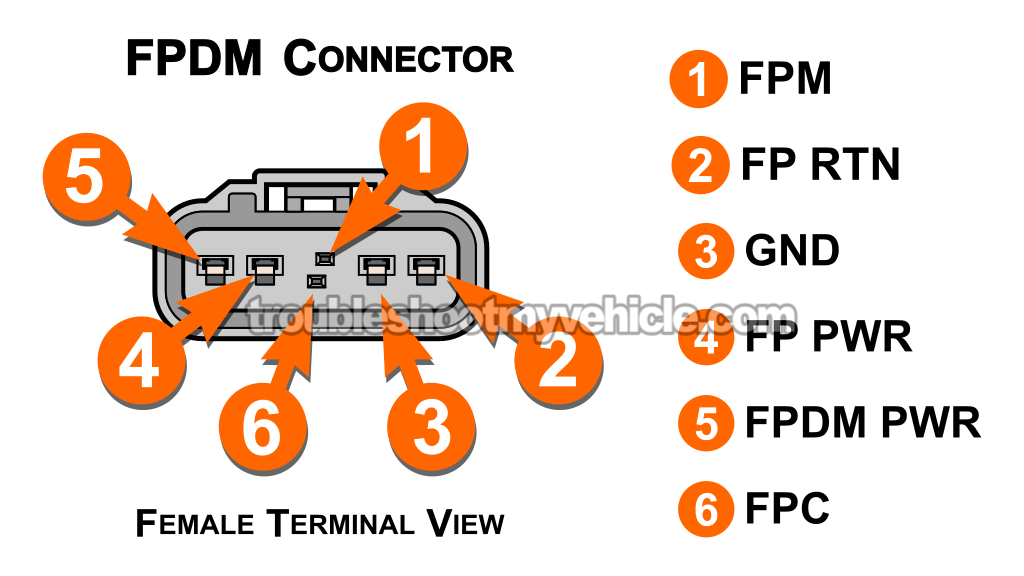

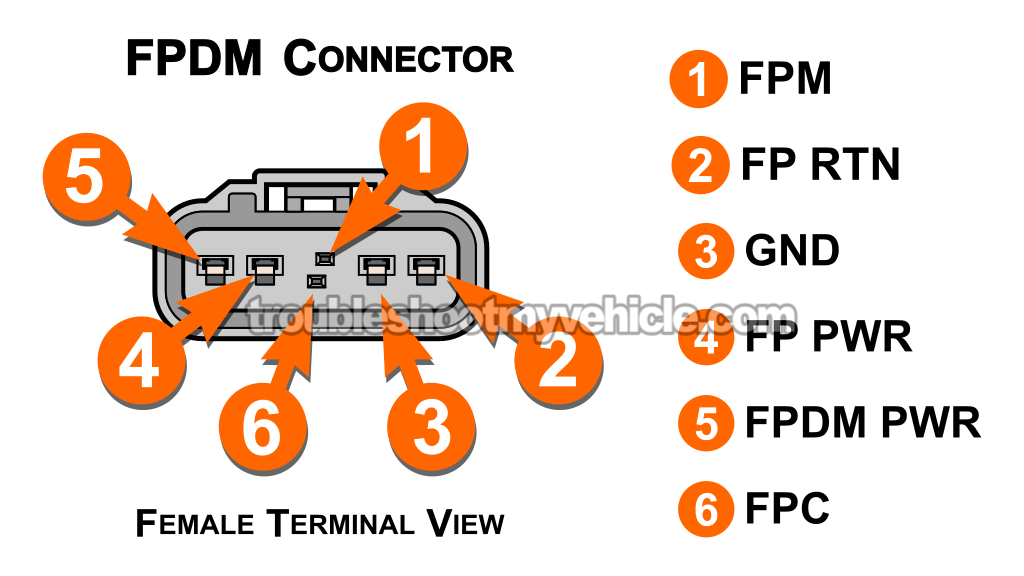

More specifically, you should find this voltage at female terminal 5 of the FPDM module's 6-wire connector.

The wire at terminal 5 of the connector will depend on the specific year of your Ford Escape (Mercury Mariner):

- 2005-2007: Pink with black stripe (PNK/BLK) wire.

- 2008: Violet with white stripe (VIO/WHT) wire.

OK, let's get started.

- 1

Disconnect the FPDM module from its 6-wire connector.

- 2

Turn the key to the RUN position (engine off) to get power flowing through the inertia switch circuit.

- 3

Set your multimeter to Volts DC mode.

- 4

Connect the black multimeter test lead to a clean, rust-free, and paint-free metal spot on the chassis.

To get the most reliable Ground, I use a battery jump-start cable to connect my multimeter test lead to the battery negative (-) post. - 5

Gently probe female terminal 5 of the connector.

Confirm that the PNK/BLK (2005-2007) or VIO/WHT (2008) wire actually connects to terminal 5. - 6

You should see close to battery voltage —between 10 and 12 Volts.

Let's interpret that test result:

CASE 1: Terminal 5 has 10 to 12 Volts. That confirms the fuel pump fuse is good, the inertia switch hasn't tripped, and power is reaching the FPDM module.

Alright, now that we know the VPWR feed is OK, let's move on to: TEST 2: Checking The PWR GND (Chassis Ground) Circuit.

CASE 2: You don't find battery voltage at terminal 5. That means the module isn't getting the power it needs, so it won't run the fuel pump.

The cause could be a bad fuel pump fuse, a tripped or failed inertia switch, or a wiring problem between the switch and the FPDM module. The next step is to track the circuit back and fix whatever's keeping power from getting through.

TEST 2: Checking The PWR GND (Chassis Ground) Circuit

Our next step is to make sure that terminal 3 is providing a chassis Ground, which is going to be present at all times —no matter what position the key is in (OFF, RUN, or START).

Now, to make sure that there's a solid connection to chassis Ground, we're going to do a multimeter voltage drop test on this circuit. This means we're going to check the Ground in action —not just do a simple continuity test in Ohms mode.

Here's some important context to help you diagnose this circuit: The black (BLK) wire that connects to terminal 3 Grounds to the vehicle's chassis.

Over time, the wire's connection point (on your vehicle's chassis) will build up corrosion from exposure to the elements —and it's even worse if you live where road salt is used (to de-ice the roads in winter). Once corrosion sets in, it adds resistance into the FPDM module's Ground path back to the battery.

That extra resistance is what causes a voltage drop. When that happens, the FPDM module may not get a clean/solid Ground under load, and that can lead to all sorts of strange issues.

That's why we're not going to rely on a simple continuity check of this circuit in Ohms mode. It doesn't show what's happening in real-world conditions. Instead, we'll run a proper voltage drop test so we can confirm the FPDM has a solid, low-resistance Ground when it's actually working.

IMPORTANT: Your Escape or Mariner's FPDM module must be connected to its connector to check the Ground wire's voltage drop.

Here's how to do it:

- 1

Reconnect the FPDM module to its 6-wire connector.

- 2

Set your multimeter to Volts DC mode.

- 3

Connect the red multimeter test lead to the PWR GND wire using a wire piercing probe.

The PWR GND (chassis Ground) wire is the BLK wire of the connector.

NOTE: Pierce the wire as far away as possible from the connector. - 4

Connect the black multimeter lead directly to the battery negative (-) post.

IMPORTANT: This connection has to be done at the battery negative (-) post. I use a battery jump start cable to extend the reach of the multimeter test lead. - 5

Have a helper turn the key to the RUN position and crank the engine. You want the FPDM module to be active and current to be flowing through the Ground circuit.

- 6

Your multimeter should show a voltage reading as close as possible to 0 Volts DC.

Any voltage reading at 5 or more Volts is considered a big problem.

Let's break down what the test result means:

CASE 1: Multimeter reads under 1 Volt. This confirms the FPDM module's PWR GND wire has a clean and solid path to the battery negative (-) post with almost no resistance.

The next step is to check if the module is actually turning on the fuel pump. Go to: TEST 3: Checking Fuel Pump Activation.

CASE 2: Multimeter reads 5 Volts or more. That means there's too much resistance in the Ground path. This kind of voltage drop can cause engine no-starts, low fuel pressure, stalling, or intermittent engine no-starts.

The cause of this voltage drop is usually corrosion or a loose Ground connection between the FPDM module, the chassis, or the battery negative (-) cable/post. Your next steps are to:

- Locate the BLK wire's chassis connection point and clean it (with sandpaper).

- Check and clean the battery negative (-) terminal and post.

- Check and clean the battery negative (-) cable where it connects to the chassis and/or engine.

Once you've cleaned the problem area and restored a solid connection, the voltage drop should fall back under 1 Volt and the FPDM module will be able to power the fuel pump correctly.

TEST 3: Checking Fuel Pump Activation

Up to this point, you've confirmed the FPDM module has both power and Ground. For this next test, we're going to see if the module is actually sending voltage and Ground to the fuel pump.

Here's some important background info that'll help understand the test we're about to perform:

- The power the FPDM module supplies the fuel pump is a constant 12 Volts.

- The Ground it supplies the fuel pump isn't a constant Ground since the FPDM module pulses it ON and OFF. In other words, it's a pulse width modulated Ground.

Now, when you're cranking the engine, the FPDM module provides an almost solid Ground (close to 100% duty cycle), so the fuel pump runs at full output and produces its maximum fuel pressure.

We can easily confirm that the FPDM module is providing power and Ground by tapping into the wire that comes out of terminal 4 and terminal 2 with a multimeter, and that's what we'll do in this test section.

Depending on the year of your particular Ford Escape or Mercury Mariner, the wires that connect to Terminal 2 and 4 are:

- Terminal 4: Fuel pump power feed (FP PWR).

- 2005-2007: White (WHT) wire.

- 2008: Yellow with gray stripe (YEL/GRY) wire.

- Terminal 2: Fuel pump Ground feed (FP GND).

- 2005-2007: Red (RED) wire.

- 2008: White with brown stripe (WHT/BRN) wire.

IMPORTANT: The FPDM module must stay connected to its 6-wire connector when checking fuel pump activation. This means you'll need to use a wire-piercing probe to connect your multimeter test leads to the FP PWR and FP GND wires. Be sure to check this section: Sealing The Wire Punctures After Testing.

Here are the test steps:

- 1

Remove some of the plastic wire loom protector and/or the black electrical tape that shields/protects the 6 wires of the FPDM module connector.

- 2

Connect the red multimeter test lead to the FP PWR wire with a wire-piercing probe.

The FP PWR wire connects to terminal 4 and will be either a WHT (2005-2007) or YEL/GRY (2008) wire.

NOTE: Pierce the wire as far away as possible from the connector. - 3

Connect the black multimeter test lead to the FP RTN wire using a wire-piercing probe.

The FP RTN wire connects to terminal 2 and will be either a RED (2005-2007) or WHT/BRN (2008) wire.

NOTE: Pierce the wire as far away as possible from the connector. - 4

Have someone crank the engine while you watch the voltage reading on your multimeter.

- 5

You should see a voltage of 9 to 12 Volts if the FPDM module is activating the fuel pump.

Let's interpret your test result:

CASE 1: Your multimeter shows 9 to 12 Volts. That's the result we want. It confirms:

- The PCM is sending the Fuel Pump Control (FPC) signal to the FPDM module.

- The module is powering the FP PWR circuit and sending voltage to the pump.

- The module is completing the FP GND circuit internally.

- The module is working as it should under load.

If you still see 0 PSI on the fuel pressure gauge after confirming both power and Ground, then the pump itself is bad. It isn't building pressure and needs to be replaced.

CASE 2: Your multimeter shows 0 Volts while cranking. That means the FPDM module isn't powering the pump.

Recheck your connections and repeat the test. If the result is still the same, the next step is to see if the PCM is commanding the FPDM module to turn the pump on. Go to: TEST 4: Checking the Fuel Pump Control (FPC) Signal.

TEST 4: Checking The Fuel Pump Control (FPC) Signal

So far, your FPDM module tests have confirmed that it's getting power (TEST 1), it has a solid chassis Ground connection (TEST 2), and that it isn't activating the fuel pump (TEST 3).

Now, we need to see if the FPDM module is getting its Fuel Pump Control (FPC) signal from the PCM. This is the signal that tells it to activate the fuel pump.

The FPC signal is a pulse width modulated signal that we can measure with a multimeter that has duty cycle (%) functionality.

I want to point out that the FPC duty cycle (%) signal tells the FPDM module how much pressure the PCM wants from the fuel pump. Here's how it works:

- A low duty cycle (closer to 5%) means the PCM is requesting lower fuel pressure.

- A higher duty cycle (closer to 50%) means the PCM wants more fuel pressure.

- At 50% duty cycle, the PCM is asking for maximum output —full fuel pump speed and full pressure.

Before we get started with the test, I want to point out one more thing: The multimeter that you need to use has to support duty cycle (%) mode. A lot of multimeters can read frequency in Hertz (Hz), but that's not going to help us here —it has to be one that can read duty cycle (%). If you don't have one, this is the one I use and don't hesitate to recommend. It reads duty cycle and doesn't cost an arm and a leg.

- Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

IMPORTANT: The FPDM module must stay plugged into its 6-wire connector during this test.

Here's how to do it:

- 1

Set your multimeter to duty cycle (%) mode.

- 2

Connect the black multimeter lead to a clean, rust-free Ground point.

My go-to method of doing this is using a battery jump-start cable, to connect the multimeter test lead directly to the battery negative (-) post. - 3

Connect the red multimeter test lead to the FPC signal wire using a wire-piercing probe.

2005-2007 → This is the LT BLU/ORG wire of the 6-wire connector.

2008 → It's the YEL/VIO wire of the connector.

NOTE: Pierce the wire as far away as possible from the connector. - 4

Have your helper crank the engine while you monitor the multimeter.

- 5

You should see a duty cycle reading around 50% during cranking (if the engine isn't starting).

NOTE: Ford considers any duty cycle between 5% and 50% as normal with the engine running. When cranking the engine to start it, the reading is usually around 50%.

Let's find out what it all means:

CASE 1: FPC signal is present (about 40%–50% duty cycle). This shows the PCM is sending the command for the FPDM module to turn the pump on. If the pump still isn't running, and you've already:

- Confirmed FPDM module is getting power (TEST 1),

- Confirmed it has a solid connection to chassis Ground (TEST 2), and...

- Confirmed it's not activating the fuel pump (TEST 3),

Then the FPDM module is toast, since it isn't responding to the FPC command. Replace the FPDM module. Before installing the new one, make sure to check the fuel pump's amperage draw (so you don't burn out the new module):

CASE 2: No FPC signal. Without the FPC signal, the FPDM module won't ever activate your Escape or Mariner's fuel pump.

This usually means the FPC circuit wire has an open-circuit problem between the PCM and the FPDM connector. The next step is to track down why the signal is missing and repair the circuit.

TEST 5: Checking The Fuel Pump Monitor (FPM) signal

NOTE: This test is optional. What we're doing here is checking the FPM (Fuel Pump Monitor) signal in case you ever need to confirm that the FPDM module is actually reporting back to the PCM.

When the FPDM module is working the way it should —meaning it's receiving VPWR power, PWR GND (chassis Ground), and the FPC command signal from the PCM— and it's actively trying to run the fuel pump, it will be sending a 50% duty cycle Fuel Pump Monitor (FPM) feedback signal back to the PCM.

It doesn't matter whether the pump itself is good or bad, but if the FPDM module is alive and talking, you'll still see it reporting a 50% feedback duty cycle FPM signal to the PCM.

Depending on your Escape or Mariner's year, the FPM signal wire is a:

- 2005–2007: Dark green with yellow stripe (DK GRN/YEL) wire.

- 2006–2010: Brown with white stripe (BRN/WHT) wire.

Alright, before we begin, I want to make you aware that the FPM signal has three possible duty cycle modes it reports back to the PCM. These are:

- 25% duty cycle: The FPDM isn't seeing a valid FPC command from the PCM.

- 50% duty cycle: Normal operation. The FPC command it received is valid, and everything looks right.

- 75% duty cycle: The FPDM is detecting a problem in the fuel pump circuit —like an open, a short, or an overcurrent condition.

So in this test, what we're really doing is confirming that the FPDM is sending some type of feedback signal back to the PCM. Whether it's 25%, 50%, or 75%, seeing any of these tells you the feedback line is alive and the module is communicating.

NOTE: To check the FPM duty cycle signal, the FPDM module must remain connected to its 6-wire connector.

Alright, let's get to it:

- 1

Set your multimeter to duty cycle (%) mode.

- 2

Connect the black multimeter lead to a clean, rust-free Ground point.

I prefer using a battery jump-start cable, to connect the multimeter test lead directly to the battery negative (-) post. - 3

Connect the red multimeter test lead to the FPM signal wire using a wire-piercing probe.

2005-2007 → This is the DK GRN/YEL wire of the connector.

2008 → This is the BRN/WHT wire of the connector. - 4

Have your helper crank the engine while you monitor the multimeter.

- 5

You should see a duty cycle reading around 50% during cranking (assuming the engine isn't starting).

NOTE: You may see a reading of 25% or 75% instead —both are valid signals and indicate the FPDM is alive and communicating.

Let's see what your test result is telling us:

CASE 1: You're seeing a 50% duty cycle FPM signal. This is the FPDM's way of saying it's healthy and not detecting any problems in the system.

Here's how to further interpret this, depending on what your fuel pressure test result is:

- If you have 0 PSI fuel pressure and the engine isn't starting, then the pump itself is bad —especially if you have confirmed in TEST 3 that the FPDM module is sending both power and Ground to the fuel pump.

- If fuel pressure is within spec but the engine still isn't starting, then the fuel pump is not the culprit. Something else in the system is keeping the engine from firing up.

CASE 2: Seeing a 25% or 75% duty cycle FPM signal. This is the FPDM telling the PCM it sees a problem.

- 25% duty cycle: The FPDM is either not receiving the Fuel Pump Control (FPC) command signal from the PCM, receiving a signal that's outside the expected "pump ON" range (5%–50%), or not seeing the PCM's "OFF" command, which should be around 70%–80% duty cycle.

- 75% duty cycle: This points to an issue between the FPDM and the pump itself. Either the pump is failing, or there's an open or short in the power or Ground wiring going to it.

CASE 3: Not seeing any FPM signal at all. This usually means the FPDM isn't powering up. The most common cause is a tripped fuel pump inertia switch, which stops power from getting to the module.

If you're confirming that power is reaching the FPDM, the next thing to make sure it has a solid chassis Ground connection. Rust, corrosion, or a loose bolt at the Ground connection can keep the FPDM module from activating and responding.

If both power and Ground are checking out good and you're still not seeing any FPM signal, then the FPDM has failed internally and needs to be replaced.

Sealing The Wire Punctures After Testing

Some of the FPDM module tests require us to hook up our multimeter leads to the FPDM connector wires using a wire-piercing probe.

The probe will make and leave a tiny puncture in the insulation. Since these wires are located underneath the vehicle, they're exposed to the elements —water, dirt, road salt, you name it. That's why we need to seal those puncture holes in the insulation once all of our testing is done.

If the puncture holes are left open, moisture will get in, corrosion will set in, and eventually the wire can fail.

Here's what to do (after completing all of the tests):

- Wrap each puncture spot with black electrical tape.

- Place the wires back into their plastic protective loom.

- Once the wires are snug in the loom, wrap the loom itself with black electrical tape.

Doing this will protect the wiring from road spray, salt, and weather. Since the FPDM and its connector sit under the vehicle, this extra step will go a long way in preventing future problems.

More Fuel Pump Troubleshooting Help

FUEL PUMP PRESSURE TESTS:

FUEL PUMP AMPERAGE DRAW TESTS:

FUEL PUMP INERTIA SWITCH TESTS:

More 3.0L V6 Ford Escape Diagnostic Tutorials

You can find a complete list of 3.0L V6 Ford Escape, Mercury Mariner, and Mazda Tribute diagnostic tutorials in this index:

Here's a sample of the diagnostic tutorials you'll find in the index:

- How To Test The MAF Sensor (2001-2007 Ford 3.0L V6 Ford Escape).

- How To Test Engine Compression (2001-2012 3.0L V6 Ford Escape).

- How To Test For A Blown Head Gasket (2001-2012 3.0L V6 Ford Escape).

- How To Test The Fuel Pump (2001-2004 3.0L Ford Escape).

If this info saved the day, buy me a beer!