In this tutorial, I'm going to explain the four tests you can perform on your 1995-2003 3.8L V6 Ford Windstar to find out if you've got a blown head gasket.

Two of these tests require no tools at all and can be done in under five minutes. The other two are a compression test (you'll need a compression tester) and a combustion-leak test using a block tester.

Every test is explained step by step so you can quickly and easily confirm or rule out a blown head gasket on your 3.8L V6 Ford Windstar.

Contents of this tutorial:

- Symptoms Of A Blown Head Gasket.

- TEST 1: Oil The Color Of 'Coffee With Too Much Creamer'.

- TEST 2: Exhaust Gases Shooting Out Of An Open Radiator.

- TEST 3: Doing A Compression Test.

- TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

- Frequently Asked Questions.

- More 3.8L V6 Ford Windstar Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Windstar: 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

3.0L/3.8L V6 TAURUS, SABLE, AND RANGER: The blown head gasket test tutorials for the Ford Taurus, Mercury Sable and Ford Ranger can be found here:

- How To Test For A Blown Head Gasket (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1990-1995 3.8L V6 Ford Taurus, Mercury Sable).

- How To Test For A Blown Head Gasket (1991-2008 3.0L V6 Ford Ranger) (at: easyautodiagnostics.com).

Symptoms Of A Blown Head Gasket

The most common cause of a blown head gasket is engine overheating, usually because:

- The fan motors stopped working.

- All the coolant leaked out and the engine was driven in that condition.

- The thermostat went bad, got stuck closed, and prevented coolant circulation.

The most common symptoms of a blown head gasket are:

- Your minivan overheats, and you already know it's not the fan(s) or thermostat.

- White smoke comes out of the tailpipe and smells like cooked antifreeze.

- Your minivan's engine won't start, even though:

- You've verified it's not an ignition issue —you've got spark on all plug wires.

- You know it's not a fuel issue —the fuel pump is delivering fuel to the injectors.

- The engine oil looks thick and has a tan or off-white color (it's mixed with coolant).

TEST 1: Oil The Color Of 'Coffee With Too Much Creamer'

About 90% of the time when one or both head gaskets fail on your 3.8L V6 Ford Windstar, coolant ends up entering the crankcase and mixing with the engine oil.

The result is that the oil turns into something that looks like coffee with way too much creamer.

Luckily, it's easy to check for this —all you've got to do is look at the oil on the engine's dipstick. Alright, I'll stop yakking and we'll get this show on the road.

Here's what you need to do.

- 1

Open the hood.

- 2

Pull out the engine's oil dipstick.

- 3

Check the color of the oil.

- 4

You'll see one of two things:

1.) The engine oil will be a creamy tan/off white color and as thick as syrup.

2.) The engine oil will be a normal color and viscosity.

Now, let's find out what each of the two results mean:

CASE 1: The color of the oil is a tan/off white color. This is not good and proves beyond a shadow of a doubt that the head gasket is blown on your 3.8L V6 Ford Windstar.

Why does the oil look like this? Mainly because the engine overheated and:

- The overheating caused one or both cylinder heads to warp, which in turn burned the head gasket(s).

- Since the head gasket's job is to keep everything sealed and separated (oil, coolant, compression, exhaust gases, etc.), once it blows, all that stuff starts mixing.

- So when coolant mixes with engine oil —as the engine runs or cranks— the result is an off-white or tan-colored mess.

CASE 2: The color of the engine oil is normal. So far so good, but you're not out of the woods yet.

You'll need to do the other two tests to further confirm a bad head gasket or exonerate the head gasket. Go to: TEST 2: Exhaust Gases Shooting Out Of An Open Radiator.

TEST 2: Exhaust Gases Shooting Out Of An Open Radiator

The second most common test to check for a blown head gasket is to see if compression, combustion, or exhaust gases are escaping into the cooling system. This test is simple —it involves removing the radiator cap from the radiator.

NOTE:

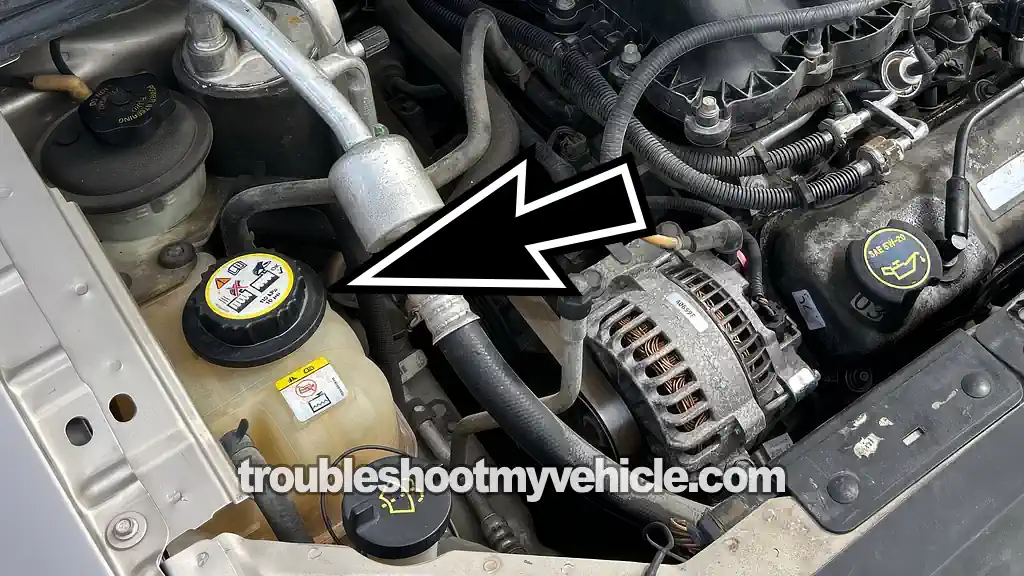

- On the 1995–1998 Ford Windstar, the radiator comes with a neck and cap (see image 1 of 1 above).

- On the 1999–2003 Windstar, however, the radiator does not have a cap —instead, it uses a coolant expansion tank located on the right side of the engine compartment (see image 2 of 2 in the image viewer above).

Once the cap is off, we'll crank the engine while watching the open radiator or expansion tank. If the coolant shoots out forcefully as the engine cranks, that's a clear sign a blown head gasket is allowing combustion gases or compression pressures to enter the engine's cooling system.

CAUTION: This test must be done with a completely cold engine. If your Windstar's engine has been running, let it cool down fully before removing the radiator or expansion tank cap —removing the cap on a hot system can cause severe burns from scalding hot coolant.

OK, let's get started:

- 1

Remove the radiator cap or expansion tank cap and check the coolant level.

If empty, add some water or coolant to bring the coolant level to its full mark/level. - 2

Now, get your helper to crank the engine, while you stand at a safe distance from the open radiator.

- 3

You'll see one of two results:

1.) The water or coolant inside the radiator or expansion tank will shoot up and out of the now open radiator.

2.) The coolant will not be disturbed. In other words, cranking the engine will have no effect on the level of the water or coolant in the radiator or expansion tank.

OK, now that the testing part is done, let's take a look at what your results mean:

CASE 1: The coolant bubbled out or shot out. This is bad news and this let's you know beyond a shadow of a doubt that the head gasket on your 3.8L Ford Windstar is blown. No further testing is required.

CASE 2: The coolant DID NOT bubble out NOR shoot out. This is the correct test result.

Your next test depends on what your Ford Windstar's engine is doing:

- If the engine starts and runs but has a cylinder misfire, your next step is to head over to: TEST 3: Doing A Compression Test.

- If the engine starts and runs but overheats within minutes for no apparent reason, your next step is to perform a: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

TEST 3: Doing A Compression Test

One of the most overlooked tests to determine if a head gasket is bad is the engine compression test.

Why? Because most folks will do the first two tests (TEST 1 and TEST 2), see no oil mixing with coolant, and no combustion gases shooting out of the radiator —and then assume everything's fine. The problem is, a lot of information out there never even mentions checking engine compression.

This test will tell you if the head gasket on your Ford Windstar has burned through between two cylinders (the photo at the beginning of this tutorial shows this type of failure).

When that happens, the compression and combustion from one cylinder leak into the other (and vice versa), and the compression readings will clearly show it.

NOTE: You can find a detailed explanation of how to perform and interpret the compression test on your 3.8L V6 Ford Windstar in this tutorial: How To Do And Interpret An Engine Compression Test (1995-2003 3.8L V6 Ford Windstar).

OK, here's what you need to do:

- 1

Remove the plastic wiper cowling to access the rear bank spark plugs.

- 2

Disable the ignition system by disconnecting the ignition coil pack from its electrical connector.

NOTE: It's important that spark is not created and delivered to the spark plug wires. - 3

Disable the fuel system. It's important that fuel not be injected into the engine.

You can do this by removing the fuel pump relay or the fuel pump fuse. - 4

Disconnect all spark plug wires (from their spark plugs) and then take out all of the spark plugs.

NOTE: Before you remove the spark plug wires, label them so that you'll be able to easily reconnect them to their proper original locations. - 5

Thread in the compression tester by hand, on the first spark plug hole you're gonna' start with.

Do not use any tools to tighten the compression tester. Hand tightening the compression tester is more than enough to get the proper results. - 6

Have a helper crank the engine. Your job is to observe the compression tester.

- 7

Once the gauge's needle stops climbing, have your assistant stop cranking the engine.

- 8

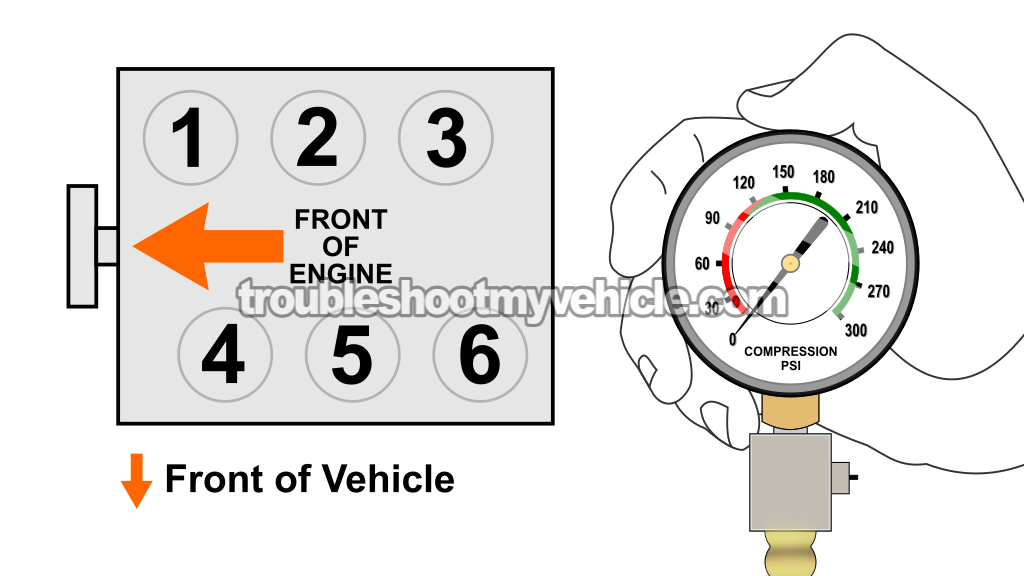

Write down the reading and what cylinder it belongs to (you can use the image in the image viewer to help you identify the cylinder) on a piece of paper.

- 9

Remove the compression tester and repeat the above steps in the remaining cylinders.

OK, let's take a look at what your results mean:

CASE 1: All cylinder compression readings where normal. These compression gauge readings confirm that the head gasket is OK and not burned at a point between two cylinders.

If the engine starts and you still suspect you've got a blown head gasket, your next step is to perform a block test. For this test, head over to: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

CASE 2: Two side by side cylinders had 0 PSI compression. This engine compression reading confirms that the head gasket is burned thru' at the point between those two cylinders. You'll need to replace both head gaskets.

TEST 4: Using A Chemical Block Tester (Combustion Leak Tester)

In some cases a head gasket has failed, but the first three tests are not able to confirm that it is.

In other words, even though one of the head gaskets has failed, the engine coolant isn't mixed with the engine oil, the coolant within the radiator isn't being shot out of the open coolant tank (while cranking the engine), and engine compression was OK. Yet the engine is overheating for no apparent reason at all.

In these hard to diagnose blown head gasket cases, the only way to find out if the head gasket is blown (or not) is to do a block test with a block tester.

You do have to buy (or borrow) the block tester, but this tool is worth every penny since it's a test that gives you a very accurate test result.

In a nutshell, this is how a block tester works:

- A blue liquid chemical, which is blue in color, is placed in the tester (see photo above).

- The tester assembly is then placed on the open radiator neck (you may have to drain some of the coolant in the radiator since this tool needs to 'gulp' some of the air inside the radiator).

- The engine is started.

- The rubber bellow is then squeezed to suck in the air up through the two fluid-filled chambers. As the air bubbles up through the fluid, it will cause a chemical reaction.

- If the blue chemical turns yellow (for gasoline engines), combustion gases are entering the radiator. This result confirms a head gasket failure, a cracked block, or a cracked cylinder head issue.

- If the blue chemical doesn't change color, you can conclude that you don't have a head gasket failure, a cracked block, or a cracked cylinder head issue.

Where can you get the chemical and block tester? At your local auto parts store or here:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Frequently Asked Questions

1.) Do I need to remove both cylinder head?

Yes, if you have confirmed that the engine has a head gasket failure, you have to remove and check both cylinder heads for cracks and warpage.

1.) How can I tell if the cylinder head is cracked?

The cylinder head has to be removed and visually inspected. If the crack is wide enough, you'll be able to easily see it.

Sometimes, a visual inspection proves inconclusive, this is why it's important to let a machine shop pressure test it for you.

2.) Do I need to resurface the cylinder head?

YES, you need to resurface both cylinder heads! You should never reinstall the cylinder head without first having an automotive machine shop resurface it. Especially if your Ford's engine overheated.

Now, of course, if you (or the machine shop) have checked it with a straight-edge and there's no warpage then, and only then is the cylinder head not resurfaced.

More 3.8L V6 Ford Windstar Diagnostic Tutorials

I've written quite a few diagnostic tutorials for the 3.8L V6 Ford Windstar, and you can find them all in this index:

Here's a sample of the tutorials you'll find for the Windstar in the index:

- How To Test The TPS (1996-1999 3.8L V6 Ford Windstar).

- How To Test The MAF Sensor (1996-1998 3.8L V6 Ford Windstar).

- How To Test The Fuel Pump (1995-1998 3.8L V6 Ford Windstar).

- How To Do And Interpret An Engine Compression Test (1995-2003 3.8L V6 Ford Windstar).

If this info saved the day, buy me a beer!