The throttle position sensor is probably one of the easiest components to test on your 1996 through 1999 3.8L V6 Ford Windstar.

This is basically due to the fact that you don't need any expensive diagnostic equipment to do it (a simple multimeter will do).

In this tutorial, I'll explain, in a step-by-step manner, how to test the TPS to find out if it's defective or not.

NOTE: If you need to test the 1995 3.8L V6 Ford Windstar TPS, see this tutorial: How To Test The TPS (1994-1995 3.8L Taurus).

Contents of this tutorial:

- Symptoms Of A Defective TPS.

- Throttle Position Sensor Circuit Descriptions.

- Where To Buy The TPS And Save.

- TEST 1: Testing The TP Signal With A Multimeter.

- TEST 2: Making Sure The TPS Is Getting 5 Volts (VREF).

- TEST 3: Making Sure The TPS Is Getting Ground (SIG RTN).

- TPS Trouble Code Won't Go Away.

- More Ford 3.8L V6 Ford Windstar Tutorials.

ES ![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor TPS (1996-1999 3.8L Windstar) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor TPS (1996-1999 3.8L Windstar) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Windstar: 1996, 1997, 1998, 1999.

3.0L/3.8L TAURUS, SABLE, AND RANGER: The TPS sensor tests for the Ford Taurus, Mercury Sable and Ford Ranger can be found here:

- How To Test The TPS With A Multimeter (1996-2007 3.0L V6 Ford Taurus, Mercury Sable).

- Lorum.

- How To Test The TPS With A Multimeter (1995-1998 3.0L V6 Ford Ranger) (at: easyautodiagnostics.com).

Symptoms Of A Defective TPS

As you're probably already aware, the throttle plate (in the throttle body), is component that regulates the amount of air that enters your Ford Windstar's 3.8L engine.

To be a bit more specific: when you step on or off the accelerator pedal, the throttle plate opens or closes, this then has the effect of accelerating or decelerating the engine.

It's the job of the throttle position sensor (TPS) to inform your Ford Windstar's fuel injection computer the throttle plate angle. Since this TP sensor plays such an important part in the fuel injection system, when this bad boy fails, engine performance suffers. And when this happens, you'll see one or more of the following symptoms:

- The check engine light (CEL) lit by one or more of the following trouble codes stored in the computer's memory.

- P0121: Throttle Position (TP) Sensor Range Performance.

- P0122: Throttle Position (TP) Sensor Low Input.

- P0123: Throttle Position (TP) Sensor High Input.

- Bad gas mileage.

- Lack of power when you accelerate the vehicle down the road.

- The engine hesitates when you accelerate the engine under load.

Throttle Position Sensor Circuit Descriptions

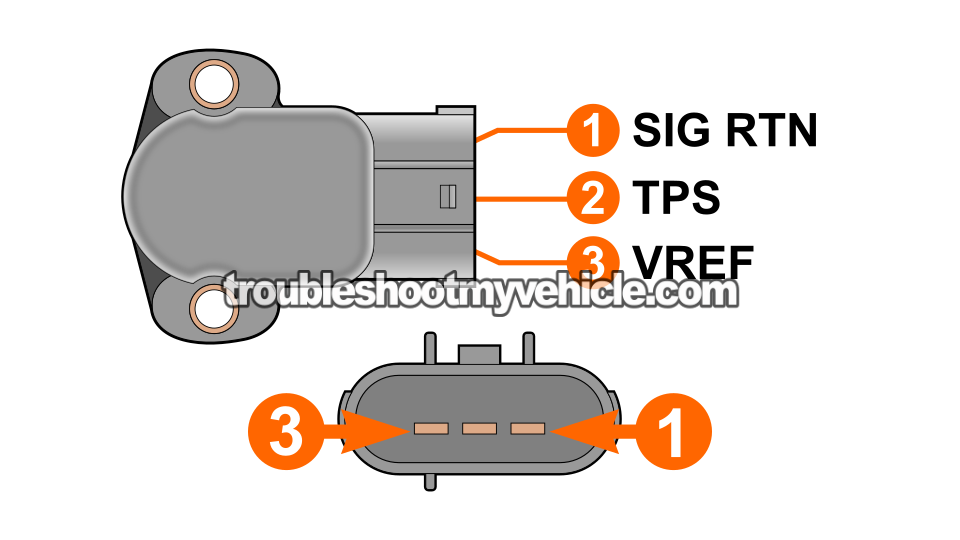

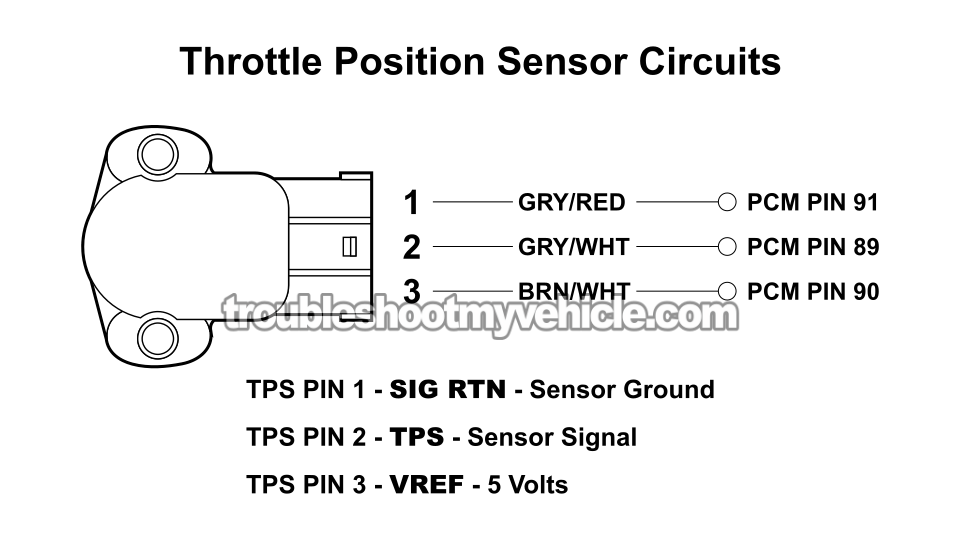

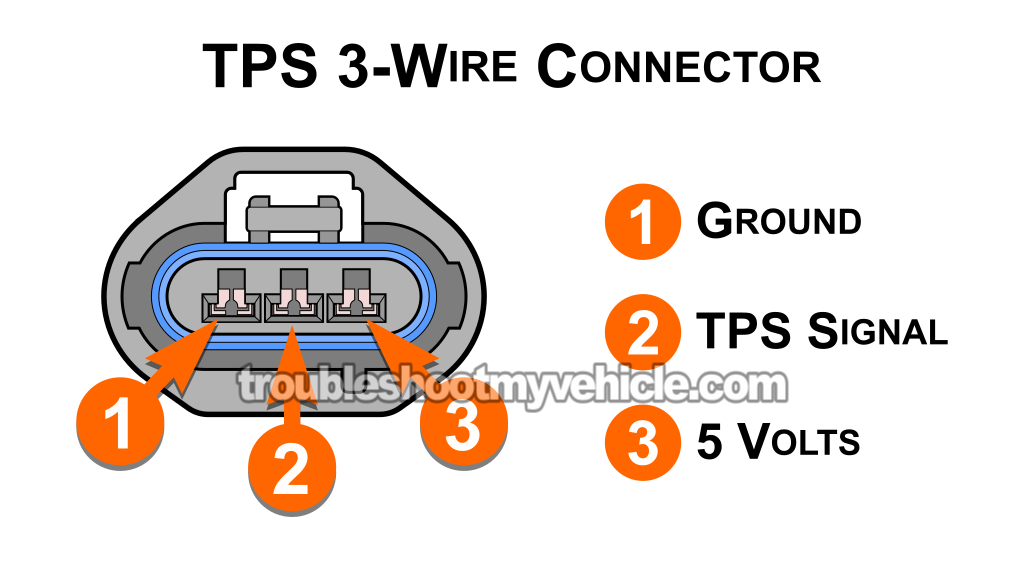

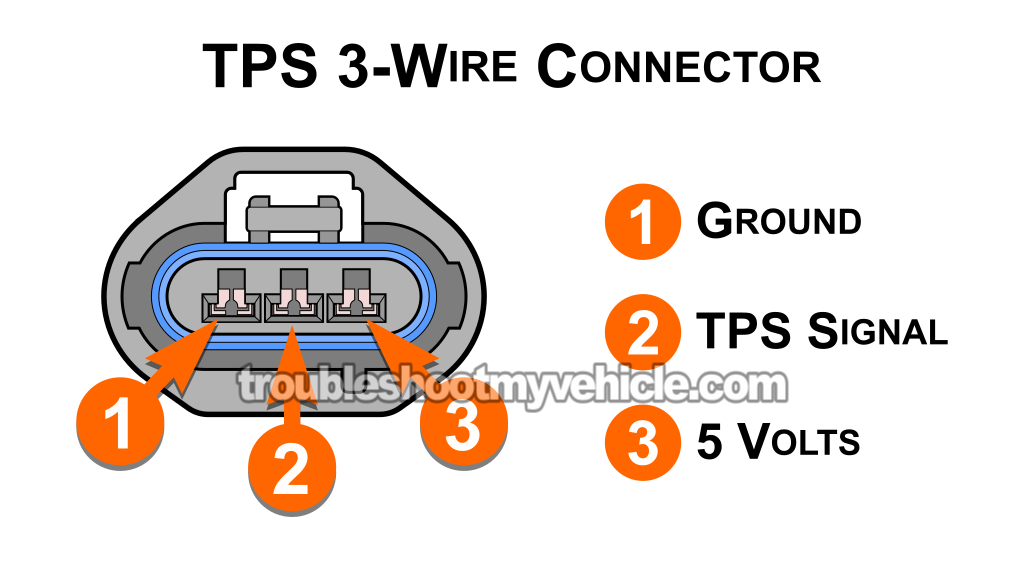

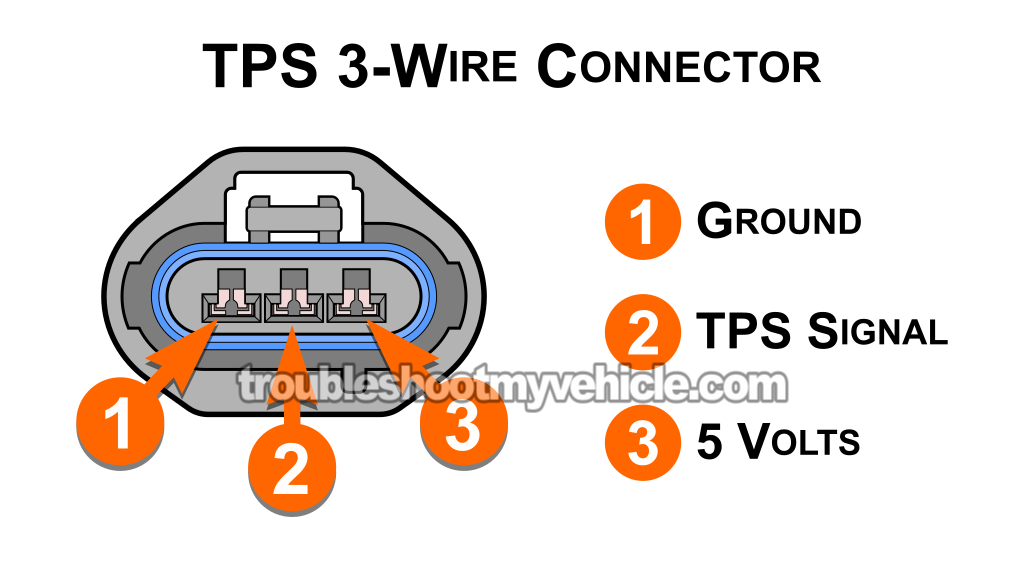

The throttle position sensor (TPS) on your 1996-1999 3.8L V6 Ford Windstar has 3 wires coming out of its electrical connector. Here is a brief description of each:

| Pin | Wire | Description |

|---|---|---|

| 1 | Gray with red stripe (GRY/RED) | Ground |

| 2 | Gray with white stripe (GRY/WHT) | TP Signal |

| 3 | Brown with white stripe (BRN/WHT) | 5 Volts |

Where To Buy The TPS And Save

The following links will help to comparison shop for the 1996-1999 3.8L V6 Ford Windstar TPS:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above TPS is the correct one for your Ford Windstar? No worries, once you get to the site, they'll ask you for your vehicle's specific information and check that that fits. If it doesn't, they'll find you the right one.

TEST 1: Testing The TP Signal With A Multimeter

In this section, we're gonna' connect a multimeter to the grey with white stripe (GRY/WHT) wire of the TP sensor electrical connector.

This will allow us to read the voltage signal that the TPS produces while we manually open and close the throttle plate.

If the TP sensor is defective (or if there's a problem in its wiring), you'll generally see that the TP signal voltage will stay stuck at a certain value regardless of the throttle plate angle.

Now to be a bit more specific, what you should see when the throttle plate is closed is around 0.4 - 0.7 Volts DC.

When the throttle plate is at its wide open position, you should see a voltage reading of about 4.4 to 4.7 Volts DC.

NOTE: To be able to perform the TP signal voltage test, the TPS has to remain connected to its electrical connector. For this reason you'll need to use a back probe or a wire piercing probe to access the signal inside the wire. This is the one I use and recommend: Goupchn 4mm Banana to Banana Plug Test Leads Kit (Amazon affiliate link).

These are the test steps:

- 1

Place your multimeter in Volts DC mode and connect the red test lead to the GRY/WHT wire of the TP sensor harness connector.

The GRY/WHT wire connects to the TPS terminal identified with the #2 in the illustration above. - 2

Ground the black multimeter test lead directly on the battery negative (-) post.

- 3

Turn the key on but don't crank or start the engine. This will power up the TPS.

- 4

Manually rotate the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 5

The multimeter should show an increasing voltage as you (or your helper) open up the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 6

The multimeter should show a decreasing voltage as you begin to close the throttle.

- 7

Using a screwdriver's handle, gently tap the TP sensor as you open and close the throttle and observer the multimeter.

The purpose (of tapping the TP sensor with the screwdriver's handle) is to see if the TP sensor shows gap's in the voltage signal. Why? Because a good TP sensor will show a continuous increasing or decreasing voltage signal even while getting tapped by the screw-driver's handle.

Let's take a look at your test results:

CASE 1: The TP signal voltage increased/decreased as you opened/closed the throttle plate. This is the correct test result and lets you know that the TPS is working correctly. The TPS itself is not the cause behind the problem on your 3.8L Ford Windstar.

CASE 2: The TP signal voltage had blanks or skips as you opened/closed the throttle plate. This test result lets you know that the throttle position sensor is defective.

CASE 3: The TPS voltage signal stayed stuck at one value when you opened/closed the throttle plate. This test result generally tells you that the TP sensor is defective.

To make sure that it is defective, the next step is to make sure the TPS has power and Ground. For this test go to: TEST 2: Making Sure The TPS Is Getting 5 Volts (VREF).

TEST 2: Making Sure The TPS Is Getting 5 Volts (VREF)

Up to this point, you've confirmed that your Windstar's TPS signal voltage stays stuck at one value whenever you open or close the throttle plate.

There's a good chance the sensor isn't getting power from the PCM. So in this section, we're going to make sure the brown with white stripe (BRN/WHT) wire —which connects to terminal 3 of the TPS connector— is delivering the 5-Volt VREF signal the sensor needs to function.

To check for the presence of this VREF voltage at terminal 3, we'll do a simple voltage test with our multimeter at that terminal.

If the 5-Volt VREF is present at terminal 3, we'll move on to check that terminal 3 has Ground in TEST 3.

Let's get going:

- 1

Disconnect the TP sensor from its 3-wire connector.

- 2

Set your multimeter to Volts DC mode.

- 3

Connect the black multimeter test lead to the battery negative (-) post.

- 4

Turn the key to the RUN position but don't crank or start the engine.

- 5

Gently probe female terminal 3 with the red multimeter test lead.

NOTE: Confirm that terminal 3 actually connects to the BRN/WHT wire. - 6

The multimeter should register 4.5 to 5 Volts DC.

Alright, let's find out what it all means:

CASE 1: Terminal 3 has 5 Volts present. So far, so good —this is the correct and expected test result.

Now that you've confirmed Terminal 3 has 5 Volts of VREF power, your next step is to make sure terminal 3 is supplying Ground to the sensor. For this test, head over to: TEST 3: Making Sure The TPS Is Getting Ground (SIG RTN).

CASE 2: Terminal 3 DOES NOT have 5 Volts present. Without this 5-Volt VREF signal, the TP sensor isn't going to function.

Double-check your test connections and retest. If you still don't see 5 Volts, you can rule out the TP sensor itself as defective or as the cause of the TPS diagnostic trouble code.

Your next step is to figure out why this VREF voltage is missing from the circuit and restore it. Once the voltage is restored, the TPS sensor will function again and the code will clear.

TEST 3: Making Sure The TPS Is Getting Ground (SIG RTN)

Up to this point, your previous two TPS tests have confirmed the following:

- The TPS signal voltage is stuck at one value, regardless of throttle plate movement (TEST 1).

- The BRN/WHT wire is delivering the 5-Volt VREF signal (TEST 2).

For our final diagnostic test, we're going to make sure the gray with red stripe (GRY/RED) wire —which connects to terminal 1 — is delivering the SIG RTN Ground from the PCM.

This Ground is only available to the sensor when the key is in the RUN or START position. For our purposes, we'll check it with the key in the RUN position but with the engine OFF.

NOTE: Be careful when testing this circuit, since this Ground is supplied internally by the PCM. If you accidentally connect battery voltage to this circuit, you'll deep fry your Windstar's PCM. The multimeter voltage test outlined below is a safe way to check for the presence of Ground in this circuit.

These are the test steps:

- 1

Disconnect the TP sensor from its 3-wire connector.

- 2

Set your multimeter to Volts DC mode.

- 3

Connect the red multimeter test lead to the battery positive (+) post.

- 4

Turn the key to the RUN position but don't crank or start the engine.

- 5

Gently probe female terminal 3 with the black multimeter test lead.

NOTE: Confirm that terminal 3 actually connects to the GRY/RED wire. - 6

The multimeter should register 4.5 to 5 Volts DC.

Let's interpret your test results:

CASE 1: Terminal 1 has SIG RTN Ground present. This is the correct and expected test result and it confirms the TP sensor is getting Ground from the PCM.

If you have confirmed the following, then you can conclude that your Ford Windstar's TP sensor is bad and needs to be replaced:

- The TP Sensor voltage signal is stuck in one value when you actuate the throttle plate (TEST 1).

- The TP Sensor is getting its 5V VREF voltage (TEST 2).

- In this test section, you've confirmed that the PCM is supplying the SIG RTN Ground at terminal 3.

CASE 2: Terminal 2 DOES NOT have SIG RTN Ground present. Without this Ground from the PCM, the TP sensor isn't going to function.

Double-check your test connections and retest. If you still don't see Ground present at terminal 1, you can rule out the TP sensor itself as defective or as the cause of the TPS diagnostic trouble code.

Your next step is to figure out why this SIG RTN Ground is missing from the circuit and restore it. Once this Ground is restored, the TPS sensor will function again and the code will clear.

TPS Trouble Code Won't Go Away

I've diagnosed cases where the fuel injection computer was accusing the TPS as defective yet the center was not.

What I found out, in these cases, was that there was some other mechanical or electrical issue fooling the computer into thinking the TPS was defective.

If this is happening in your case, the following suggestions may help you save some time and money:

- Check to see if the TP sensor's wiring harness connector is broken.

- Specifically, check the connector's locking tab. It's a very common problem for the locking tab to break and cause a false contact condition.

- Check that the throttle plate idle stop screw isn't misadjusted.

- What I've seen quite a bit, is that the idle stop screw has been adjusted to increase the engine's idle RPM to mask a rough idle condition. But doing this usually causes the computer to set a TPS trouble code.

- Check the continuity of the wires between the fuel injection and the throttle position sensor.

- The idea behind this test is to make sure that there isn't an open-circuit in the wiring between the TPS and the fuel injection computer.

- Check that the computer isn't defective. This can seem like quite a challenge but it's possible. This is how you can conclude that you have a defective fuel injection computer on your hands:

- Eliminate the throttle position sensor as defective first.

- Make sure that the wiring between the TPS and the computer has continuity. In other words there aren't any short-circuits or open-circuits in the wiring between these two.

- Confirm that the fuel injection computer's Ground wires are actually feeding it Ground. The best way to do this is to do a voltage drop test on each fuel injection computer's Ground wires.

- Confirm that the fuel injection computer has power in each of its power wires.

- After eliminating the TPS itself, after verifying the continuity of the TP sensors 3 wires (between its connector and the fuel injection computer), after verifying that the fuel injection has good Ground and power; then and only then can you conclude that there might be a problem with the computer internally.

More Ford 3.8L V6 Ford Windstar Tutorials

You can find a complete list of 3.8L V6 Ford Windstar tutorials in the following index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The MAF Sensor (1996-1998 3.8L V6 Ford Windstar).

- How To Test The Fuel Pump (1995-1998 3.8L V6 Ford Windstar).

- How To Test For A Blown Head Gasket (1995-2003 3.8L V6 Ford Windstar).

- How To Do And Interpret An Engine Compression Test (1995-2003 3.8L V6 Ford Windstar).

If this info saved the day, buy me a beer!