TEST 1: Fuel Trim Check

The very first thing you need to do and the most important, after pulling the diagnostic trouble code, is to see if there truly does exist a chronic lean condition.

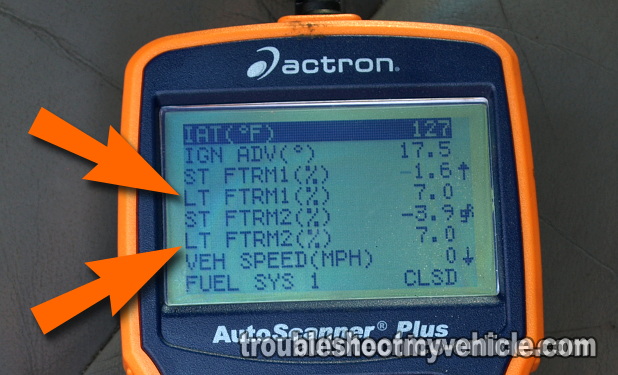

And this can easily be done by checking the Long Term Fuel Trim values (for bank 1 and bank 2) with your scan tool in Live Data mode (Don't have a scan tool? Need a scan tool? Check out my recommendation: Actron CP9580 Scan Tool).

In case you're wondering what the heck Long Term Fuel Trim is., this is the computer's way of letting you know if it's adding or removing fuel by injecting more or injecting less gasoline. A negative number tells you that it's injecting less. A positive number tells you it's adding fuel.

Since the trouble codes indicate a lean condition (P0171 and P0174) on both banks of cylinders, both Long Term Fuel Trim 1 and 2 should be in their maximum positive number range as the PCM adds fuel to compensate for the perceived vacuum leak or failing sensor (whichever it may be).

This is what you need to do:

- 1

Connect your scan tool to the diagnostic connector and turn the key on.

Once the scan tool activates, go to Live Data mode and scroll down to the PIDs labeled LT FTRM1 and LT FTRM2. - 2

Start the engine and let it warm up to about 190° F (88° C).

Letting the engine warm up to this temperature, before continuing to the next step, will ensure the accuracy of your test results.

You can check the coolant temperature with your scan tool by scrolling to the PID labeled: Coolant. - 3

Note the LT FTRM1 and LTFTRM2 values, once the engine has reached the indicated coolant temperature.

The normal values should be moving between a positive and a negative value. The range should be between 10% and -10% (negative 10%).

If there is a lean condition present (either because a vacuum leak is present or due to something else), the LT FTRM values will be above 10% and will not come down to a negative value. They will usually hover around 20%.

Let's take a look at your test results:

CASE 1: The LT FTRM1 and LT FTRM2 values moved between 10% and -10%. This tells you that the lean condition is intermittent.

An intermittent lean condition can be hard to solve since the problem is not present all of the time. Take a look at the section: I've Done All Of The Tests And I Still Have Codes P0171, P0174 for some suggestions.

CASE 2: The LT FTRM1 and LT FTRM2 values were above 10% and/or near 20% and did not come down to a negative value. This result confirms that your vehicle is suffering thru' a bonafide lean condition and needs further testing. Go to: TEST 2: Inducing a Rich Condition.

TEST 2: Inducing A Rich Condition

OK, after confirming that you do have a bonafide lean condition, you can start doing some specific tests to find out where this Lean condition exists, if it exists.

Now to find out if the lean condition is being caused by a real vacuum leak or by the oxygen sensor, the next step is to check the performance of the oxygen sensor or sensors. This can be very easily done and I'll go into some detail about it.

The best way to check the oxygen sensors (the pre catalytic converter oxygen sensors) is to create a rich condition while observing your scan tool (in Live Data mode) to see if the oxygen sensor numbers go up to 800 millivolts (0.800) to 1 Volt.

This is what you need to do:

- 1

With your scan tool still connected to the diagnostic connector and the engine running, scroll down to the oxygen sensor PIDs.

These PIDs will be labeled O2S11 and O2S21. - 2

Make sure the coolant temperature, as recorded on your scan tool, is still above 190° F (88° C).

- 3

While you observe the oxygen sensor values, have a helper spray a little bit of carburetor cleaner into the intake manifold via a small vacuum hose with the engine running.

I want to emphasize spraying carb cleaner spray into a small vacuum hose. You can not disconnect the intake air duct hose (while the engine is running) from the throttle body to spray carb cleaner into the throttle while the engine is running. - 4

If the oxygen sensors are working normally, as soon as the carburetor spray hits the inside of the intake manifold (via the vacuum hose), your scan tool should read 0.900 Volts for both O2S11 and O2S21.

You can repeat step 3 several times, if you need to make sure of your test result.

Alright, let's interpret your results.

Let's interpret your test results:

CASE 1: Now, if when you sprayed carb cleaner down a small vacuum hose with the engine Running (and as you eye-balled the scan tool) and the O2S11 and O2S21 values shot up and stayed at 0.8 mV to 1 V, then you now know that both oxygen sensors are OK and not the cause of the P0171, P0174 lean codes. The next step is to check for vacuum leaks.

CASE 2: If either one of two oxygen sensor values did not shoot up as the carb spray was being sprayed, then that O2 sensor is bad and needs to be replaced. This is the one causing the diagnostic trouble code.

As soon as you replace the bad O2 sensor, you can see if it solved the DTC by checking the fuel Trims again. If the problem was solved, they will be oscillating between a positive and negative number constantly.