This tutorial will show you how to test the continuity of the mass air flow (MAF) sensor circuits to see if they are shorted to each other.

Before testing the continuity of the MAF sensor circuits (wires), you need to first make sure that the MAF sensor itself is OK. The cool thing is that the MAF sensor can be easily tested with a simple multimeter.

If you haven't tested the MAF sensor, the following will explain the test in a step-by-step manner: How To Test The Ford MAF (4.2L, 4.6L, 5.4L) (at: easyautodiagnostics.com).

Contents of this tutorial:

- Important Safety Precautions.

- What Tools Do I Need To Test The Wires Between the MAF Sensor and PCM?

- Circuit Descriptions Of The MAF Sensor.

- TEST 1: Check The Basics First.

- TEST 2: Checking Continuity Of The MAF SIG Circuit.

- TEST 3: Checking Continuity Of The MAF RTN Circuit.

- TEST 4: Checking MAF SIG Circuit For Short to Power or Ground.

- TEST 5: Checking MAF RTN Circuit For Short to Power.

- More Ford 4.6L, 5.4L Diagnostic Tutorials.

Important Safety Precautions

TIP 1: Never probe the front of the PCM 104 pin connector.

Checking the continuity of the MAF sensor circuits, between the PCM connector and the MAF sensor connector, requires using a multimeter. But, you should never probe the front of the 104 pin PCM connector.

Probing the front of the PCM connector with the multimeter probe (or any other probe) can/will damage the round metal terminals (of the connector). If this happens, you're looking into a MAJOR nightmare since you'll have to replace the entire engine wiring harness.

TIP 2: The battery negative terminal needs to be disconnected before you unplug the PCM from its 104 pin connector.

This is important for two specific reasons: One, it'll avoid damaging the PCM due to a voltage spike. Two: It'll avoid damaging your multimeter by making sure the circuit you're testing doesn't have power.

TIP 3: Use the recomended tools to test the continuity between the PCM and the TPS.

If you don't have the tools (and here I'm talking about a Ford EEC-V breakout box), then I suggest taking your vehicle to a professional repair shop for the tests described in this tutorial.

Don't let the fact that you don't have the appropriate tools discourage you. My suggestion is to take a look at the tutorial and familiarize yourself with the test procedures. This will help you comunicate the issue (and what you want done) more effectively if you decide to take your Ford vehicle to a repair shop.

What Tools Do I Need To Test The Wires Between The MAF Sensor And PCM?

Before we start testing, you need to know that a special tool is needed to test the continuity of the wires between the mass air flow (MAF) sensor and the PCM 104 pin connector (it'll also let us check the live signals coming from and going to the PCM).

This tool is a breakout box. What does it do? It allows us to safely check the circuits that connect to the PCM without having to hack into the wires of the PCM connector.

As you can see in the photo in the image viewer, this tool resembles a ‘box’ that has two connectors. One connector connects to your Ford's PCM. The other connector connects to the PCM's engine wiring harness PCM connector. The ‘box’ part of the tool has 104 slots that can be probed with a multimeter test lead.

The breakout box is designed to help us avoid:

- Back probing (with a back-probe) the back of the PCM connector to test a specific circuit.

- Probing the front of the PCM connector (something that should NEVER be done since this will damage the terminal being probed).

- Using a wire-piercing probe on the wire of the PCM connector that's being tested.

Currently, there are two flavors of this breakout box: The OTC-3235 Ford EEC-V 104 Pin Breakout Box and the Ford Rotunda 014-00950

You may also be wondering if you can test the wires between the TPS and the PCM without a breakout box and the answer is yes. Because of the risk of damage to the PCM 104 pin connector and the availability of the breakout box for the Ford vehicles covered by this tutorial, this tutorial focuses on the use of the breakout box.

Here's a list of other tools you'll need (besides the 104 pin breakout box):

- Multimeter.

- Wiring diagram.

- PCM 104 pin connector pin-out chart.

Circuit Descriptions Of The MAF Sensor

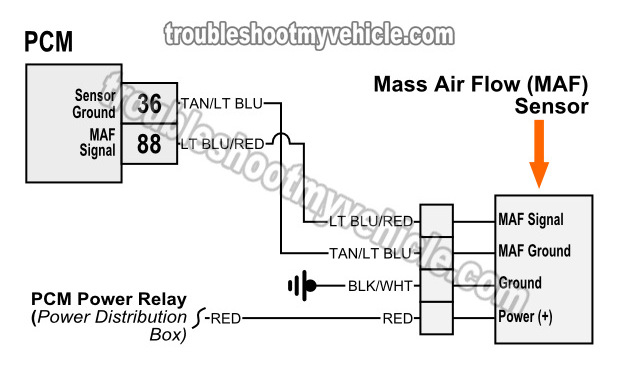

As you're already aware, the MAF sensor has 4 wires sticking out of its connector.

Each wire has a specific job to do and carries a specific signal to or from the MAF sensor.

Only 2 out of the 4 wires connect directly to the powertrain control module (PCM = fuel injection computer).

Since we're here to test the 2 wires that connect to the PCM, here's a brief description of each:

| MAF Sensor Circuit Descriptions | ||

|---|---|---|

| PCM Pin | Wire Color | Description |

| 36 | TAN/LT BLU | MAF SIG

|

| 88 | LT BLU/RED | MAF RTN

|

| 71, 97 | RED | VPWR

|

| 24, 51, 76, 77, 103 | BLK/WHT | PWR GND

|

The following simplified wiring-diagrams may also be of help:

- MAF Sensor Circuit Wiring Diagram (1997-1998 4.6L, 5.4L V8 Ford F150, F250 Light Duty) (at: easyautodiagnostics.com).

- MAF Sensor Circuit Wiring Diagram (1999 4.6L, 5.4L V8 Ford F150, F250 Light Duty) (at: easyautodiagnostics.com).

OK, if all of the above check out OK, then your next step is to make check the continuity of the MAF sensor's wires between the PCM connector and the MAF sensor's connector.