Testing the ignition coil pack on your 1997-2000 4.2L V6 E150 or E250 isn't difficult at all. In this tutorial I'll explain the entire process step-by-step.

I've packed this tutorial with as much information as possible so that you can easily find out if the ignition coil pack is doing its job or has failed.

Contents of this tutorial:

- Symptoms Of A Bad Ignition Coil Pack.

- What Tools Do I Need To Test The Ignition Coil?

- Circuit Descriptions Of The Ford Coil Pack Connector.

- Basic Operating Theory Of The Ford Coil Pack.

- Precautions, Do's And Don'ts.

- TEST 1: Testing For Spark At The Spark Plug Wire.

- TEST 2: Testing For Spark At The Ignition Coil Pack.

- TEST 3: Testing For Spark At The Ignition Coil Pack.

- TEST 4: Testing The Power (12 Volts) Circuit.

- TEST 5: Activation Signal For Cylinders 1 And 5.

- TEST 6: Activation Signal For Cylinders 2 And 6.

- TEST 7: Activation Signal For Cylinders 3 And 4.

- TEST 8: Checking The IC Activation Signals.

- Other Things That Can Cause A Misfire.

APPLIES TO: This tutorial applies to the following vehicles:

- 4.2L Ford E150: 1997, 1998, 1999, 2000

- 4.2L Ford E250: 1997, 1998, 1999, 2000

WIRING DIAGRAM: The following diagram may come in handy:

NOTE: The 2001-2003 4.2L V6 E150 and E250 vans use a different style of ignition coil pack. You can find that tutorial here:

F-Series Pickups: You can find the ignition coil pack tests for the 1997-2000 4.2L V6 Ford F150/F250 pickups here:

- How To Test The Ignition Coils (1997-2000 4.2L V6 Ford F150, F250 Light Duty) (at: easyautodiagnostics.com)

Symptoms Of A Bad Ignition Coil Pack

When the ignition coil pack or the spark plug wires are bad, your 4.2L V6 Ford E-Series van will display one or more of the following symptoms:

- Misfire Codes: You'll see one or more of the following codes:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder 1 Misfire.

- P0302: Cylinder 2 Misfire.

- P0303: Cylinder 3 Misfire.

- P0304: Cylinder 4 Misfire.

- P0305: Cylinder 5 Misfire.

- P0306: Cylinder 6 Misfire.

- Engine Performance Issues: You may see one or more of the following:

- The engine idles rough and wants to stall.

- When you accelerate the van, it has no power.

- Bad Gas Mileage: Since the engine isn't running all six cylinders, it has to work harder, thus consuming more fuel.

- Engine No-Start: The engine will crank but not start (if more than 3 ignition coil towers are not creating spark).

- Rotten egg smell: You'll notice a rotten egg smell coming out of the tailpipe from the unburned fuel overloading the catalytic converter.

What Tools Do I Need To Test The Ignition Coil?

To successfully use this information to diagnose and troubleshoot the ignition coil pack, you'll need a few specific tools. Don't worry, none of this stuff is expensive, here's the list:

- A multimeter.

- A 12 Volt automotive test light.

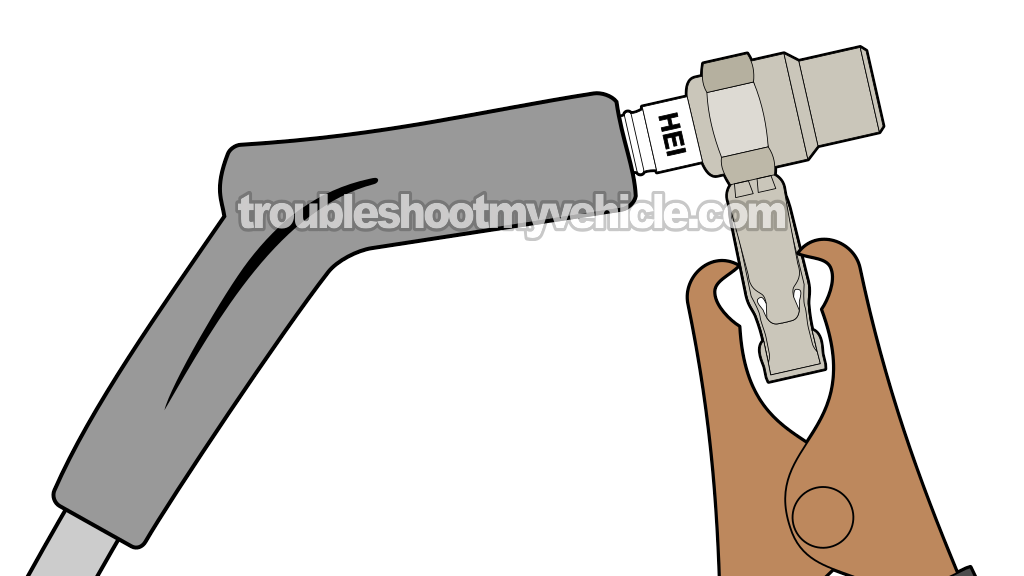

- An HEI spark tester

- This tool is a must have (don't have an HEI spark tester? Need to buy one? You can buy it here: OTC 6589 Electronic Ignition Spark Tester).

- Battery jump start cables.

- Someone to help you crank the engine.

To troubleshoot and diagnose a bad coil pack on your Ford van, an HEI spark tester is a must have tool. Using the wrong tool or method will have you chasing a wrong diagnostic test conclusion and effectively wasting your time and money.

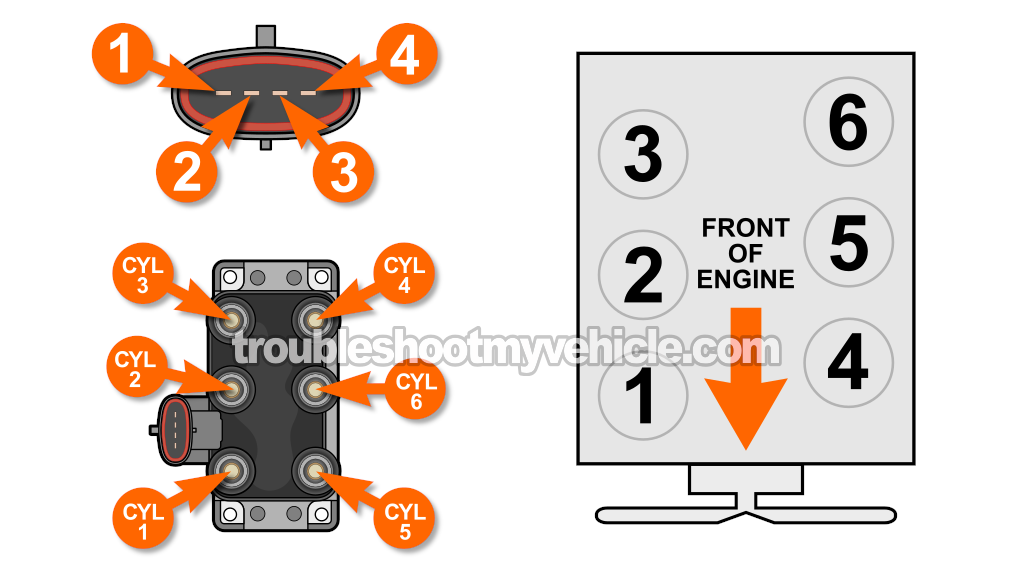

Circuit Descriptions Of The Ford Coil Pack Connector

The ignition coil pack connector has 4 wires coming out of it. These are the circuit descriptions for the 1997-1999 4.2L V6 E150 and E250:

| Terminal | Wire | Description |

|---|---|---|

| 1 | Red with light green stripe (RED/LT GRN) | 12 Volts (in START/RUN) |

| 2 | Dark blue with light green stripe (DK BLU/LT GRN) | IC Activation Signal Cylinders 1 & 5 |

| 3 | Pink with white stripe (PNK/WHT) | IC Activation Signal Cylinders 2 & 6 |

| 4 | Red with light blue stripe (RED/LT BLU) | IC Activation Signal Cylinders 3 & 4 |

Basic Operating Theory Of The Ford Coil Pack

Your Ford van's fuel injection computer is the one that controls the activation of the ignition coil. In a nutshell, here's what happens when you turn the key to crank and start the engine:

- The engine starts to crank, inducing the crankshaft position (CKP) sensor to start producing its CKP signal.

- The CKP signal, upon being received by the PCM along with other necessary sensor information, starts to do its little song and dance and sends three different ignition coil activation signals (thru' separate wires) to the ignition coil pack.

- The coil pack is made up of three separate ignition coils. Each ignition coil within the coil pack has two towers that feed spark to two cylinders at the same time.

- The ignition coil activation signal is the computer switching the Primary Current (12 Volts), flowing thru' each ignition coil within the coil pack, ON and OFF by interrupting their Ground path. It's this signal that makes the ignition coils fire spark.

- Each ignition coil (that make up the coil pack) gets its own activation signal from the fuel injection computer.

- As each individual ignition coil, within the ignition coil pack, gets its activation signal, it fires spark to two 'paired cylinders' at the exact same time (in what's known as the Waste Spark method).

- Cylinders 1 and 5 get spark simultaneously from coil 1.

- Cylinders 2 and 6 get spark simultaneously from coil 3.

- Cylinders 3 and 4 get spark simultaneously from coil 2.

You don't need to memorize any of this, but the one thing you do need to keep in mind is that two cylinders get spark at exact same time. You're gonna see the phrases 'paired cylinders' and 'non-paired cylinders' quite a bit in this tutorial.

Knowing what 'paired cylinder' means will help you successfully diagnose the ignition coil pack (not to mention it'll help you make sense of the tests in this tutorial).

These are the paired cylinders:

- Cylinders 1 and 5.

- Cylinders 2 and 6.

- Cylinders 3 and 4.

Precautions, Do's And Don'ts

Most of the testing that you'll be doing is with the engine cranking, so take all necessary safety precautions to keep your fingers, hands and entire self safe. Here are a few other tips and suggestions:

- Do not use a regular spark plug instead of a spark tester to test for spark.

- Do not remove the spark plug wire from the spark plug or the ignition coil while the engine is cranking to test for spark.

- Start your diagnostic from TEST 1, do not skip around from test to test unless instructed to do so by the TEST you are currently on.

- Once again, use the recommended/indicated tools for all of your tests.

TEST 1: Testing For Spark At The Spark Plug Wire

I'm gonna ask you to test all six spark plug wires for spark. To do this, you'll need to disconnect each wire from the spark plug and connect it to a spark tester. The thing is that pulling the spark plug wire off of the spark plug without a spark plug puller can damage them.

What usually happens is that when you pull on the wire (to disconnect it from the spark plug) without a spark plug puller, its metal terminal usually stays stuck to the spark plug. If this happens, you'll either need to reattach the terminal to the wire (which is not hard but it's a pain) or replace the wire set.

I'm not asking you to buy a tool here, just letting you know this is a very common issue with these spark plug wires and the best way to avoid this hassle is to use a spark plug wire puller tool.

Also, it's critical that you use a spark tester -any spark tester will do. The one I own and use is the HEI spark tester because this bad boy is accurate and I don't need to adjust it or interpret the color of the spark. You can see it and buy it here: OTC 6589 Electronic Ignition Spark Tester (at: amazon.com)

These are the test steps:

- 1

Remove the spark plug wire (high tension cable) from the spark plug.

- 2

Attach your spark tester to high tension wire.

- 3

Connect the spark tester to the battery negative (-) terminal with a battery jump start cable.

- 4

Have your helper crank the vehicle as you stand at a safe distance from the engine.

The engine may or may not start, either way be careful. - 5

As the vehicle cranks or starts, observe the spark tester.

- 6

You're gonna get one of two results: spark or NO spark.

- 7

Now repeat this test on the other spark plug wires.

IMPORTANT: Read the following options carefully to interpret your NO SPARK result or results. Remember that some cylinders get spark from the same ignition coil within the coil pack (since the coil pack is made up of 3 individual ignition coils that have two towers each). So if you get a NO SPARK result from two spark plug wires, you need to verify if they're from paired cylinders or from unpaired cylinders.

CASE 1: You got spark from all six spark plug wires. This tells you that the ignition coil pack and spark plug wires are OK. The cause of your misfire condition is not due to a bad ignition coil pack. Go to: Other Things That Can Cause A Misfire to see further tips and suggestions.

CASE 2: You got NO spark from only one spark plug wire. The next step is to check for spark directly on the coil pack tower that feeds that spark plug wire with spark. Go to: TEST 2: Testing For Spark At The Ignition Coil Pack.

CASE 3: You got NO spark from two spark plug wires that connect to spark plugs for paired cylinders 1 & 5, or 2 & 6, or 3 & 4. The next step is check for spark directly on both towers (one at a time of course).

For this test go to: TEST 3: Testing For Spark At The Ignition Coil Pack.

CASE 4: You got NO spark from two spark plug wires that DO NOT connect to paired cylinders. The next step is to test each coil pack tower directly for spark one at a time.

For this test go to: TEST 2: Testing For Spark At The Ignition Coil Pack.

CASE 5: You got NO spark from none of the spark plug wires. This usually indicates that power is missing from the power circuit or that the crankshaft position sensor is bad.

To find out, go to: TEST 4: Testing The Power (12 Volts) Circuit.