In this tutorial I'm gonna' show you how to test the starter motor in a step-by-step manner. No expensive diagnostic tools needed!

All of the tests are explained in plain English so you can easily find out if the starter motor is bad or not.

NOTE: You'll notice that the photos I'm using are of the starter motor out of the vehicle; this is to make it easier to show you where to make your test connections. You don't need to remove the starter motor from your Ford to follow the test instructions in this tutorial.

Contents of this tutorial:

- Important Tips.

- Symptoms Of A Bad Starter Motor.

- Tools Needed To Test The Starter Motor.

- TEST 1: Applying 12 Volts To The S Terminal.

- TEST 2: Verifying The 12 Volt Start Signal.

- TEST 3: Testing The Starter Motor Relay's Activation Signal.

- TEST 4: Voltage Drop Testing The BAT (+) Cable.

- More Ford E150, E250, and E350 Tutorials.

APPLIES TO: This tutorial applies to the following vehicles with a 4.9L, 5.0L, or 5.8L engine:

- Ford E150: 1992, 1993, 1994, 1995, 1996.

- Ford E250: 1992, 1993, 1994, 1995, 1996.

- Ford E350: 1992, 1993, 1994, 1995, 1996.

STARTER MOTOR CIRCUIT WIRING DIAGRAMS: The following wiring diagrams may come in handy:

- Starter Motor Circuit Diagram (1992-1993 Ford E150, E250, E350).

- Starter Motor Circuit Diagram (1994-1995 Ford E150, E250, E350).

Important Tips

TIP 1: Before you start testing the starter motor, make sure that the battery is fully charged. This is super critical, otherwise you may end up getting the wrong test result.

TIP 2: The battery cable terminals and the battery posts should be clean and corrosion-free before starting the tests.

TIP 3: Read the entire article first so that you can familiarize yourself with the tests.

TIP 4: Use jack stands for safety.

You'll need to raise your Ford E-Series van to access the starter motor. Do not trust the jack alone to keep your vehicle up in the air while you're underneath it!

TIP 5: Take all necessary safety precautions, such as wearing safety glasses while working underneath the vehicle. Be alert and think safety all of the time.

Symptoms Of A Bad Starter Motor

For the most part, when the starter motor fails, the engine will not turn over when you turn the key to crank and start the engine.

In some cases, the starter motor fails intermittently, which means that it'll work fine most of the time, but it won't now and then.

Here's a list of the most common symptoms will see where the starter motor has failed:

- You turn the key to crank up and start the engine but nothing happens.

- You got someone to help your jump-start your Ford, but this didn't help get the engine to crank and start.

- You've bought a brand new battery (thinking that was the solution to the 'no-crank' condition) and this did not get your Ford to crank and start.

- Turn the key to start your Ford and all you hear is a small knock and nothing else.

Although the above list is not a complete list of symptoms, the theme that runs thru them and any other related symptom is that the engine will not turn over when you turn the key to start it.

NOTE: If the starter motor is actually cranking the engine over, then you're not dealing with a no-crank condition. It sounds like the engine does not start. The following tutorial will help you troubleshoot an engine no-start problem:

Tools Needed To Test The Starter Motor

You don't need expensive test equipment to test the starter motor on your E-Series van, but you do need a few things. These are:

- Jack.

- You'll need to raise your vehicle to gain access to the starter motor.

- Jack stands.

- Remote starter switch.

- If you'd like to see what a remote starter switch looks like, you can follow this link: Innova 3630 Remote Starter Switch (Amazon affiliate link).

- You can either buy this tool online or you can buy it at your local auto parts store (AutoZone or O'Reilly Auto Parts, etc.).

- Multimeter or a 12 Volt automotive test light.

- If you don't have a multimeter or need to upgrade yours, check out my recommendation here: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (Amazon affiliate link).

- A wire piercing probe.

- This tool is not an 'absolute must-have tool' but I can tell you from experience that it makes it a whole lot easier to probe the S terminal wire for the Start Signal.

- If you'd like to see what this tool looks like, you find out more about it here: Wire Piercing Probe Tool Review (Power Probe PWPPPPP01).

- A helper.

As you can see, you don't need anything expensive. OK, let's get started with the first starter motor test.

TEST 1: Applying 12 Volts To The S Terminal

The first thing that we're gonna' do is apply 12 Volts to the starter motor solenoid's S terminal to see if the starter motor will crank the engine.

If the starter motor cranks the engine, then you can conclude that the starter motor itself is OK.

A remote starter switch will come in super handy when applying 12 Volts to the starter motor solenoid's S terminal.

Also, I use a wire piercing probe to pierce the S terminal wire and then connect my remote starter switch to it and proceed from there; I suggest you do the same. You can see what this tool looks like here: Wire Piercing Probe Tool Review (Power Probe PWPPPPP01).

IMPORTANT: Remove the key from the ignition switch for this test.

OK, this is what you'll need to do:

- 1

Raise your E-Series van and place on it jack stands. Remember, the only way to gain access to the starter motor is from underneath the vehicle.

- 2

Disconnect the battery negative (-) terminal.

You'll reconnect it back in one of the following steps, for now, it's a safety precaution as you set up the test. - 3

Attach a remote starter switch to the S terminal of the starter motor solenoid.

This is easier said than done, so take your time and make sure the connection is on the S terminal of the starter motor solenoid.

Also, in case you're wondering, you can leave the starter motor solenoid's S terminal wire connected to the engine's wiring harness connector or not, the test will work either way. - 4

Reconnect the battery negative (-) cable to the battery negative (-) post.

- 5

Now, apply 12 Volts to the S terminal wire of the starter motor starter solenoid with your remote starter switch.

- 6

You'll get one of two results:

1.) The starter will activate and will turn over the engine.

2.) The starter motor won't do a thing.

Let's take a look at what your test results mean:

CASE 1: The starter motor cranked the engine. This is the correct and expected test result.

With this test result we can usually conclude that the starter motor is not receiving a 'Start' signal if the starter motor does not crank the engine when you turn the key to start it.

The next step is to verify if the 'Start' signal is missing. Go to: TEST 2: Verifying The 12 Volt Start Signal.

CASE 2: The starter motor DID NOT crank the engine. Double check your connections and repeat the test.

If the starter motor still does not crank the engine, then this usually means that the starter motor is bad and needs to be replaced.

Before you run out to buy it, you need to make sure that the battery (+) cable does not have a voltage drop issue. Go to: TEST 4: Voltage Drop Testing The BAT (+) Cable.

TEST 2: Verifying The 12 Volt Start Signal

When you turn the key to crank the engine, the starter motor solenoid receives a 12 Volt 'Start' signal from the starter motor relay.

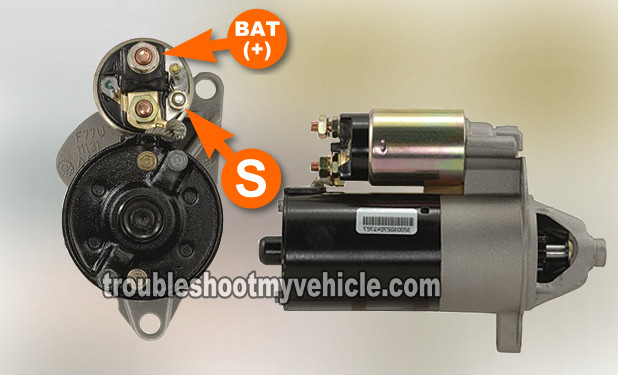

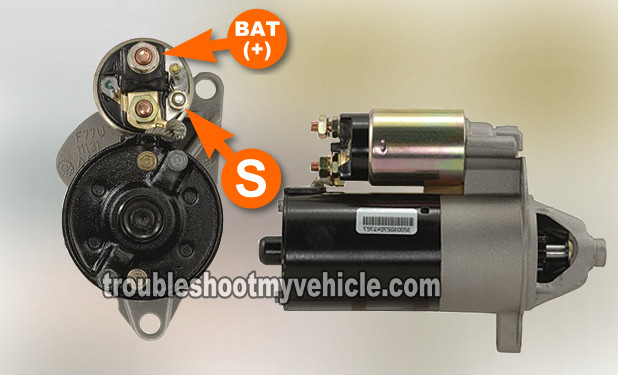

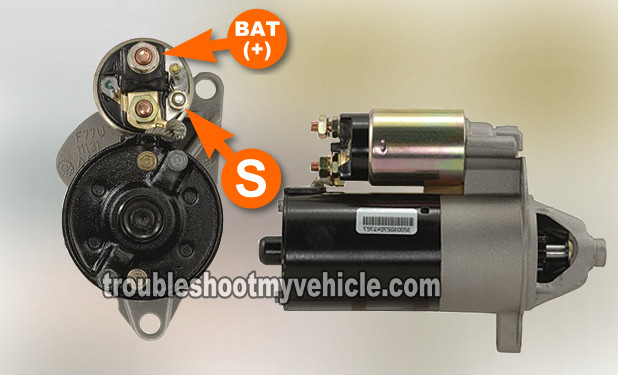

This 'Start' signal is delivered to the starter motor solenoid's S terminal. In the photo above, the S terminal is labeled with the letter S.

In this test section, we're gonna' confirm the delivery of this 12 Volts 'Start' signal to the starter motor solenoid's S terminal.

OK, let's get testing:

- 1

Set your multimeter to Volts DC mode.

- 2

Connect the red multimeter test lead to the wire that connects to the starter motor solenoid's S terminal using an appropriate tool.

Don't know which wire is the S terminal wire? This is the one that connects to the smaller of the three studs on the starter motor solenoid.

The S terminal wire (circuit) is the one that delivers the Start (Crank) signal from the starter motor relay. - 3

Ground the black multimeter test lead directly on the negative (-) battery terminal using a jump start cable.

You can also Ground it on the engine, if you can find a clean, unpainted and rust-free spot of metal. - 4

When everything is ready, have your helper turn the key to crank the engine.

- 5

Your multimeter should read one of two results:

1.) 10 to 12 Volts DC.

2.) 0 Volts DC.

OK, let's examine your test result:

CASE 1: Your multimeter DID NOT register 10 to 12 Volts. This test result tells you that the starter motor is not receiving an activation signal from the starter motor relay.

The next step is to make sure that the starter motor relay is getting its activation signal. Go to: TEST 3: Testing The Starter Motor Relay's Activation Signal.

CASE 2: Your multimeter registered 10 to 12 Volts. This is the correct and expected test result and it tells you that the starter motor is receiving an activation signal from the starter motor relay.

At this point, you have:

- Confirmed that directly applying 12 Volts to the starter motor solenoid's S terminal makes the starter crank the engine (TEST 1).

- Confirmed in this test section that the 'Start' signal is being delivered to the starter motor.

With these test results you can conclude that at this time the starter motor problem is not present. You'll need to wait till the starter motor does not crank the engine to continue troubleshooting the problem.

TEST 3: Testing The Starter Motor Relay's Activation Signal

The starter motor relay is the component that sends the 'Start' signal to the starter motor solenoid's S terminal.

For this to happen, the starter motor relay has to receive its own activation signal.

So in this section, we'll make sure that the starter motor relay receives this activation signal.

LOCATION: The location of the starter motor relay is in the right front corner of the engine compartment, near the battery.

These are the test steps:

- 1

Disconnect the red with light blue stripe (RED/LT BLU) wire from the starter motor relay.

The orange arrow in the photos above points to the RED/LT BLU wire. - 2

Place your multimeter in Volts DC mode.

- 3

Connect the black multimeter test lead to the battery negative (-) post.

- 4

Connect the red multimeter test lead to the RED/LT BLU wire you just disconnected from the starter motor relay.

- 5

Have your helper turn the key to start the engine.

- 6

Your multimeter should register 10 to 12 Volts DC.

Let's take a look at what your results mean:

CASE 1: The multimeter registered 10 to 12 Volts DC. This is the correct and expected test result and it lets you know that the starter motor relay is receiving an activation signal.

You can conclude that the starter motor relay is bad (and needs to be replaced) if you have:

- Confirmed that the starter motor does crank the engine when you directly apply 12 Volts to the starter motor solenoid's S terminal (TEST 1).

- Confirmed that the starter motor solenoid's S terminal wire IS NOT delivering a 12 V 'Start' signal (TEST 2).

CASE 2: The multimeter DID NOT register 10 to 12 Volts DC. This test result tells you that the starter motor relay is not receiving an activation signal. Without it, the starter motor relay won't send a 'Start' signal to the starter motor.

The most likely causes of this missing starter motor relay activation signal is:

- A misadjusted park/neutral safety switch.

- Fuse 7 of the interior fuse box is blown (1994-1996 only).

- A bad ignition switch.

Your next step is to test the park/neutral safety switch, check fuse 7 (1994-1996 only), and test the ignition switch.

TEST 4: Voltage Drop Testing The BAT (+) Cable

In this test section, we're gonna' find out if the starter motor is receiving the total amount of amperage it needs to crank the engine.

We'll accomplish this by doing a simple multimeter voltage drop test on the battery positive (+) cable.

Let's get going:

- 1

Place your multimeter in Volts DC mode.

- 2

Connect the red multimeter test lead on the center of the battery positive (+) post.

NOTE: The battery must remain connected to both its cables. - 3

Connect the black multimeter test lead to the stater motor solenoid's stud that connects to the battery positive (+) cable.

The orange arrow labeled with BAT (+) in the photo above points to this stud.

Maintain the black multimeter test lead in this position throughout the next step. - 4

When everything is ready, have your helper crank the engine.

Although the starter motor won't crank the engine, your helper has to turn the ignition switch to start the engine for the voltage drop test to work. - 5

While your helper is trying to crank the engine the multimeter should register 0.5 Volts or less (0.5 V is really 0 Volts).

If there's a problem in this circuit, your multimeter will register some voltage, usually 5 Volts or above.

OK, let's take a look at what your results mean:

CASE 1: Your multimeter indicated NO voltage drop (0.5 Volts or less). This is the correct and expected test result and it confirms that the starter motor is getting the full amount of voltage and amperage the battery can deliver.

You can conclude that the starter motor is bad and needs to be replaced if:

- The starter motor does not crank the engine when you applied 12 Volts to the starter motor solenoid's S terminal (TEST 1).

- The starter motor solenoid's S terminal is receiving 10 to 12 Volts (TEST 2).

- There's no voltage drop in the circuit (wires) that connect the starter motor solenoid BAT (+) terminal to the battery's positive (+) post.

Now before you remove the starter motor, do one more thing: Turn the engine manually (using a 1/2 ratchet and the appropriate socket). This will verify that the engine is not mechanically locked up.

CASE 2: Your multimeter registered 5 Volts or more. This result tells you that a voltage drop does exist and that it's keeping the full amount of amperage the battery can provide from reaching the starter motor.

The solution is to:

- Disconnect both battery cables from the battery and thoroughly clean their terminals.

- Disconnect the cables at the starter motor relay and clean their round terminals.

- Disconnect the cable that's attached to the starter motor solenoid's BAT (+) terminal and clean its round metal terminal.

Cleaning the cables' round terminals should be done with a small piece of sand paper. Once all cable terminals are clean, reconnect everything and try cranking the engine. If the voltage drop was the cause of the no-crank condition, the engine will now crank and start.

More Ford E150, E250, and E350 Tutorials

You can find a complete list of tutorials for the full-size Ford E-Series vans here:

Here's a small sample of the tutorials you'll find:

- Manifold Absolute Pressure MAP Sensor Test (Ford 4.9L, 5.0L, 5.8L).

- Ignition Coil Test -No Spark No Start Tests (Ford 4.9L, 5.0L, 5.8L).

- How To Troubleshoot A No Start (Ford 4.9L, 5.0L, 5.8L).

- Testing A Blown Head Gasket (Ford 4.9L, 5.0L, 5.8L).

- How To Test Engine Compression (4.9L, 5.0L, 5.8L).

If this info saved the day, buy me a beer!