STARTER TEST 2: Voltage Drop Testing The Battery Cable

One of the things I've seen a lot, that will keep your Quad 4 equipped Pontiac (or Chevy, Olds, Buick) from cranking and starting, is hidden corrosion on the battery positive (+) terminal. As you may already know, this is the cable that provides the starter motor will the juice it needs to crank your Honda car or mini-van.

If this cable is unable to deliver all of the battery's available power, the starter motor won't be able to crank the engine.

This is where the voltage drop test saves the day since it will give you a ‘YES this circuit is OK’ or a ‘NO, this circuit has a problem’ type test result.

Alright, let's get started:

- 1

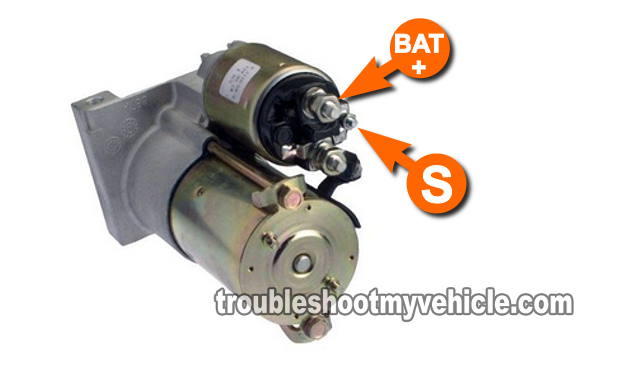

With your multimeter still in Volts DC mode, probe the stud on the starter motor, that has the big cable attached to it with a nut (see the photo in the image viewer), with the red multimeter test lead. Do not probe the cable's round terminal, probe the stud itself.

- 2

With the black multimeter test lead, probe a clean spot right in the center of the battery positive cable bolt. Do not probe the battery positive (+) terminal, but the center of the bolt that attaches the battery positive (+) terminal to the battery.

- 3

When you're ready, have your helper crank your car while you observe the multimeter.

Although the starter motor won't crank the engine, a voltage drop test of this cable (circuit) requires that you turn the key and crank the engine. - 4

Once again, you'll get one of two results on your multimeter:

1.) The multimeter will register a 0 Voltage which indicates no voltage drop.

2.) The multimeter will register a Voltage, usually 5 Volts or more and this test results means that there is a voltage drop in the circuit and this is not good.

OK, now that the testing part is done, let's take a look at what your results mean:

CASE 1: Your multimeter indicated NO voltage drop (which is 0.5 Volts or less). This confirms that the battery positive cable is corrosion free and supplying all of the available battery power to the starter motor.

With this test result you can replace the starter motor with confidence. Now, in case you're reading this article because you've already replaced the starter motor and that did not solve your 'no-crank' condition, I recommend doing the following tests:

1.) Turn the engine manually (using a 1/2 ratchet and the appropriate socket). This will verify that the engine is not mechanically locked up. After all, it could've thrown a rod and this is what is keeping the engine from cranking. Or the A/C compressor could be locked up too (I have seen this a lot!) and this will also make you think it's a bad starter motor.

2.) Bench test the starter motor. You could have received a defective starter motor right out of the box! Bench testing a starter motor is easy and you can find the step-by-step instructions here: How To Bench Test A Starter Motor (Step By Step) (at: easyautodiagnostics.com).

CASE 2: Your multimeter registered 5 Volts or more. This result confirms that a voltage drop indeed exists in this circuit. In non-technical terms, this means that corrosion is keeping the cable from delivering all of the battery's available power. This corrosion almost always shows up on the terminal ends of the cable.

To solve this issue all you have to do is clean both ends of the battery positive cable. By both ends, I mean the end that connects to the battery positive post and the end that attaches to the starter motor solenoid. In case you're wondering how to clean the end that attaches to the starter motor solenoid, you can use sand paper to sand both sides of the round terminal.

Once you're done and have reconnected both ends of the cable, re-test or simply crank up the car. More than likely it'll now crank and start.

Related Test Articles

You can find more 2.4L GM test articles here: GM 2.4L Index Of Articles.

If this info saved the day, buy me a beer!