Interpreting Your Compression Test Results

The very first thing you'll notice (and kinda' comes as a shock) is that none of the compression readings are exactly the same! This is normal up to a certain point.

It's when they vary by a whole lot (more than 15%) that this becomes an issue. And so, in this section we'll interpret the numbers you wrote down, from testing the compression of each cylinder.

So in this section, I'm going to explain how you can find out if that low engine compression value is causing a problem or not.

OK, you can do this one of two ways: You can calculate this 15% difference with pen and paper or you can use my low compression calculator. You can find the low compression calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that the vehicle I'm working on produced the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 175 PSI |

| #6 | 170 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: ‘Wet’ Engine Compression Test.

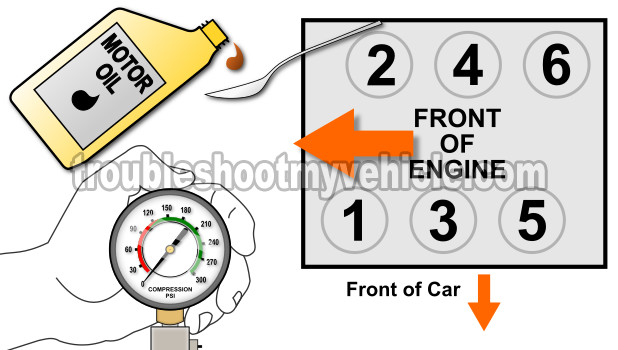

TEST 2: Wet Compression Test

To find out if the low cylinder compression is due to worn out cylinder head valves or worn out piston rings, the next step is to do a ‘Wet’ compression test. Knowing if the problem is in the cylinder head valves or in the piston rings will help you decide what you need to replace (and how much it's gonna' cost) before you do any tear down.

To be a bit more specific, this test will tell you if you only need to have the cylinder heads worked on or if you only need to have the block worked on. Both of these options are not the ideal since just repairing one and not the other is not a good idea. Why?

Because by repairing only one, but not the other, you're only delaying the inevitable by about six months, which is: you're gonna' have to replace or repair the entire engine anyway.

OK, getting back to the test at hand, what you're gonna' do is add about 2 tablespoons of oil to the cylinder (that recorded no or low compression in the previous test) and then check its compression once again.

What will happen is that if the low compression values is due to worn piston rings, the compression value will go up from the previous one you got doing the Dry compression value.

If the compression value does not go up (from the previous one), then you'll know that the problem lies in the cylinder head valves.

OK, to get this pot of water boiling, this is what you need to do:

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the ‘Dry’ compression test.

The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder.

Do not use any type of tool to tightened the compression tester. Hand tight is fine. - 3

When all is set up, have your helper crank the engine.

- 4

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before).

2.) The compression value will stay the same.

Let's take a look at your test results:

CASE 1: The compression value shot up. This tells you that the piston compression rings are worn out and thus the problem is in the bottom end.

The reason why the compression value shot up, with the engine oil added, is because the oil is aiding the piston rings to create a near perfect seal.

Since the oil is not letting the compression escape by the rings, this results in your compression gauge reading a higher value than with the ‘dry’ compression test.

CASE 2: The compression value stayed the same. This confirms that the problem is in the cylinder head valves.

The reason why the compression reading did not shoot up, is because the engine oil can not help the intake or exhaust valve seal the compressed air. Therefore, the compression value will stay the same.

Why An Engine Compression Test?

It doesn't happen very often, that one or more (but not all) engine cylinders wear out at an accelerated rate than the others but it does happen enough that you should be aware that a compression test should be an integral part of your misfire code diagnostic strategy.

So many things can cause a misfire condition or misfire codes (if the vehicle is OBD II equipped: P0300, P0301, P0302, P303, P0304, P0305, P0306) to set that you could think they are nearly impossible to troubleshoot. Well, the good news is that every possible cause can be tested to see if indeed it is the one causing the problem! And you'll find most of those testing articles here at troubleshootmyvehicle.com.

More 3.8L GM V6 Tutorials

What if you tested the engine compression on your 3.8L Chevy or Pontiac, or Buick, or Oldsmobile and the compression test indicates the engine is healthy? Well, the following articles will help you to track down the misfire condition on the other systems or components that can cause misfires:

- GM 3.8L Fuel Injector Noid Light Test.

- How To Test The Fuel Injectors (GM 3.8L).

- How To Diagnose Misfire Codes P0300-P0306 (GM 3.8L).

- GM 3.8L Ignition System Tests (this info is found at easyautodiagnostics.com).

Reader's Real Life Case Studies And Solutions

In this section is input and feedback from all of the folks who have had a similar issue with their vehicle and found a solution. If you're one of them, I want to thank you for sharing your experience with all of us!

If you want to share your repair and/or diagnostic experience, you can use the contact form below.

Real Life Case Study 1

Vehicle: 2000 Buick Park Ave. (Base) 3.8L V-6, 172,000 miles

Trouble Codes: P0303 and P0304

Complaint: LOW COMPRESSION ON #3 AND #4 “I lost a water pump going up a 6% grade incline at high speed and wasn't watching the temp. gauge. I used some Duraseal to overcome some coolant leak problems, but still had a 70 lb. compression reading on #3 and #4 and was throwing P0303 and P0304 codes. Even after I solved the coolant leaks, which I don't know if those were from the head gasket or the intake manifold, I was still getting those codes. Another compression test gave the same results, and when we added a spoonful of oil (for a wet compression test) it only came up ten pounds, to about 80 psi. At that point, I figure that it may be a valve problem, a burnt seat or a bent valve, etc.”

Test Notes: The DuraSeal headgasket treatment I used (without any sodium silicate in it's formula) did seal the head gasket problem, but made no difference on the compression values, obviously). I wanted to believe that I could solve the problem without tearing into the heads, but the reality is that even if the intake manifold gasket were bad, or if the plastic intake manifold were warped (as the local Buick Dealer Tech suggested), that would not change the compression problem. The initial compression test indicated a problem and I wanted to believe a head gasket problem was the source of that loss of compression. But even after doing the chemical fix which worked I still had loss of compression. With the wet test showing little improvement, the inescapable conclusion was that the valves were compromised. I didn't do the leak down test to confirm if it was the intake valves or the exhaust valves. All I knew is that the valves were bad. ”

“At that point I looked at the cost of paying someone to tear it all down, then magnaflux the heads and fix the bad valves and put it all back together: not a small amount. The problem is that even once you do that, if you do that, you then have a strong upper engine working on a 170,000 lower engine. The prospect is that then as many times it has been seen that later the lower end is blown out and you have to start all over again to do a ring job. Tilt!”

Repair: REPLACED ENGINE “I called the S V******* area salvage yards to find a low mileage used engine in the L*** area. The salvage yard gave me a price of $1,500 to buy the engine AND install it. He used my existing plastic intake manifold, not the metal one on the 'new' engine, and got it to work.”

Advice: “That is the key thing I learned. IF YOU ARE LOSING COOLANT OVER TIME, CHECK THE WEEP HOLE ON YOUR WATER PUMP FIRST. That is the first place to look. If I had done that and replaced the water pump when it was telling me it was about to go, I would have avoided all the time and cost of the repairs I incurred. But now I am even better off, in a way, with a low mileage engine to go with my already rebuilt tranny. ”

Courtesy of: Dave Cramer

Notes: You can read Dave's entire post here: Dave's Post.

If this info saved the day, buy me a beer!