How To Read The 3X 18X CKP Images

If you've read any of my ‘how to’ tutorials, you'll notice that I avoid using wiring diagrams.

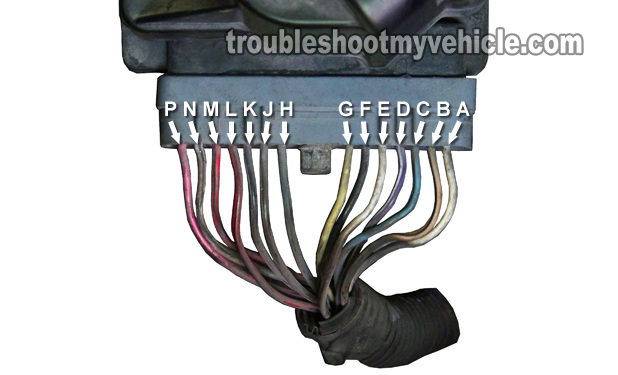

Where possible, I use the a real photo of the connector and this article is no exception.

In trying to keep things as simple and to the point, the photos used in this article only highlight the circuits (wires) that you'll be testing, to find out if the 3X 18X CKP sensor is good or bad.

If you're having trouble making sense of the letters M, N, H and G, this section will help you to ‘make heads or tails out of’ it.

- 1

On the connector, of the ignition control module (ICM), on your 3.8L GM equipped vehicle, you can see that GM has molded the letters M thru' A.

- 2

GM, as most of the electronics industry, has omitted the letters i and o. This is normal and done intentionally.

- 3

As your looking down at the ignition control module (and its connector) the letter P circuit starts on your left and the letters regress to the letter A from there.

OK, let's get this show on the road and start testing. The crankshaft position sensor test starts in the next subheading.

CKP TEST 1: 3X Sync Signal

The 3X, 18X CKP sensor is located behind the crankshaft pulley but we're not gonna test it there.

The way this test is designed, you'll be testing the crankshaft position sensor at the ignition control module's connector. This will be the easiest and fastest way to get to the signals going to and coming from the sensor.

CAUTION: Since you'll test the sensor while the engine is being cranked (by hand, that is). You'll need to jack up the car or mini-van, and so it goes without saying (but I'm gonna' say it anyway): Be careful, think safety all of the time, take all precautions, and use a jack stand to hold the car up in the air. Do not trust the jack!

IMPORTANT: The CKP sensor and the ignition control module must remain connected to their connector during the test to read the 3X Sync signal.

These are the steps:

PART 1:

- 1

Raise the front of the vehicle and lower it on jack stands. You need to have the car or mini-van up in the air to comfortably hand turn the engine.

- 2

Remove the front passenger-side wheel. If the wheel spins as you're trying to break the lug nuts loose, have someone sit inside the vehicle and step on the brake pedal. This will keep the wheel from moving and facilitate the removal of the lug nuts.

- 3

Remove the plastic water splash shield that protects the crankshaft pulley and serpentine belt from water.

- 4

Disable the fuel system by disconnecting all 6 fuel injectors. This important! By disabling all 6 fuel injectors, you'll keep the vehicle from possibly starting as you perform the test.

- 5

Locate the ignition control module's connector and disconnect it from the ignition control module (ICM). Once disconnected, remove enough of the plastic wire loom protector and black electrical tape that shields the wires of the ICM connector.

This is where you'll be testing for the 3X-18X CKP sensor signals.

IMPORTANT: Once you've removed enough of this tape, reconnect the connector to the ignition control module (ICM).

PART 2:

- 6

Place the multimeter in Volts DC mode.

- 7

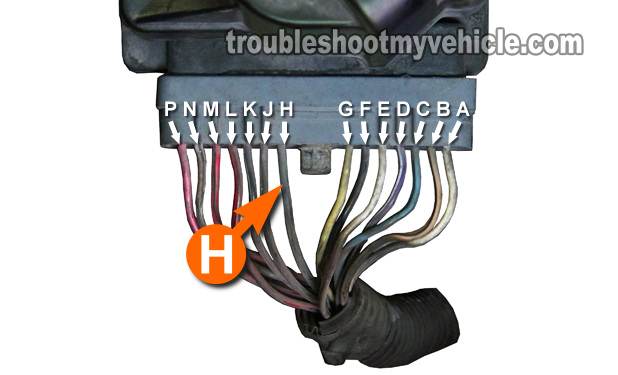

Connect the red multimeter test lead (and an appropriate tool) to the wire labeled with the letter H in the image above.

You can use a back probe or a wire-piercing probe. To see what a what this tool looks like, click here: Wire Piercing Probe. - 8

Connect the black multimeter test lead to the battery negative (-) terminal.

- 9

Turn the crankshaft pulley by hand in a clock-wise direction while you observe your multimeter's display.

Do not use the starter motor to crank the engine, since this test will not work if you use the starter motor. You can use a 1/2 inch ratchet, an extension and the appropriate socket, on the crankshaft pulley to turn it. - 10

The multimeter to display an ON/OFF voltage as you manually turn the engine.

ON is when the multimeter registers 5 to 6 Volts and OFF is when the multimeter registers 0 Volts.

OK, let's find out what your multimeter test results mean, choose from one of the following CASES:

CASE 1: The multimeter registered the ON/OFF 5 to 6 Volts DC as you manually turned the engine. This result indicates that the CKP sensor is creating a good 3X Sync signal and that this signal is reaching the ignition control module.

The next step is to verify the 18X CKP signal, for this test, go to: CKP TEST 2: 18X Signal.

CASE 2: The multimeter DID NOT register the ON/OFF 5 to 6 Volts DC as you manually turned the engine. This result indicates that the 3X-18X CKP sensor is not creating the 3X Sync signal and that it's probably bad.

Most folks would stop here and replace the crankshaft position sensor and around 95% of the time this solves the problem.

But, I recommend that you do a couple more tests, to be able to really condemn it. The other things you need to check are that the CKP sensor is generating the 18X signal, getting both power and Ground, go to: CKP TEST 2: 18X Signal.