STARTER TEST 2: Applying 12 V To The S Terminal

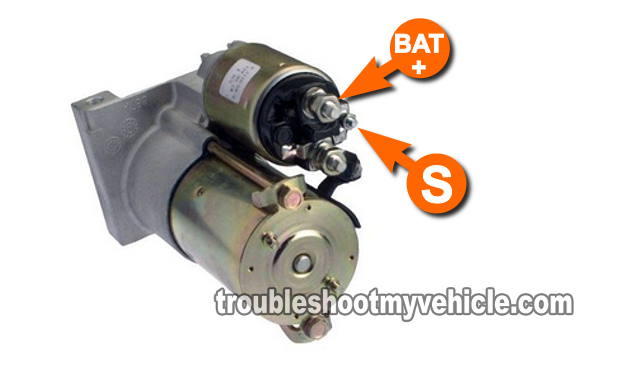

The next step, in troubleshooting the starter motor, is to apply 12 Volts directly to the S terminal of the starter motor solenoid (with a jumper wire connected to the battery positive (+) terminal).

You can also use a remote starter switch. If you need to see what one looks like, you can see it here: Actron CP7853 Remote Starter Switch For 6V And 12V Automotive Starting Systems.

This is a very simple test, but you do have to take one very important precaution:

IMPORTANT: Remove the key from the ignition switch before starting this test. This will prevent the engine from starting, in case the starter motor is OK.

OK, this is what you'll need to do:

- 1

Disconnect the wire that attaches to the S terminal of the starter motor solenoid.

- 2

Using a jumper wire that's long enough, or a remote start switch, apply 12 Volts to the S terminal of the starter motor solenoid.

- 3

As you apply these 12 Volts (to the S terminal of the starter solenoid), you'll get one of two results:

1.) The starter will activate and will turn over the engine.

2.) The starter motor won't do a thing.

Let's take a look at what your test results mean:

CASE 1: The starter motor cranked the engine. This means that the starter motor is good and that you have an electrical issue keeping the starter motor from cranking the engine.

Also, since the starter motor did come alive and cranked the engine, this result lets you know beyond a shadow of a doubt that the starter motor is good and that you need to look at the ignition switch, or neutral safety switch or Fusible Link as the cause of the no-start condition on your car or mini-van.

CASE 2: The starter motor DID NOT crank the engine. This usually means that your starter motor is bad and needs to be rebuilt or replaced.

I suggest one more test and this is to test the battery cable (that attaches to the starter motor solenoid) for corrosion. This can be accomplished very easily with a voltage drop test. Go to: STARTER TEST 3: Voltage Drop Testing the battery Circuit.

STARTER TEST 3: Voltage Drop Testing The Battery Circuit

So far in your testing, you have verified that the battery is fully charged and in STARTER TEST 1 you confirmed that the starter motor is being supplied with the crank signal (when your helper turned the key to crank the car).

The next step is to make sure that the battery positive (+) cable that attaches to the starter motor's solenoid is supplying full battery voltage and Amperage to the starter motor.

If the starter motor isn't getting full battery current, usually due to hidden corrosion somewhere on the cable, the starter motor won't be able to crank the engine.

We can easily verify this by doing a simple voltage drop test.

These are the test steps:

- 1

Place your multimeter in Volts DC mode.

- 2

Attach the red multimeter test lead to the center of the bolt that attaches the positive (+) battery cable to the battery.

NOTE: The spot on this bolt, which the multimeter test lead will be touching, has to be clean and rust-free.

You may need two helpers for this test step, since someone will have to hold the red multimeter test lead onto the battery positive (+) terminal bolt and someone else inside the vehicle (to crank it when everything is set up). - 3

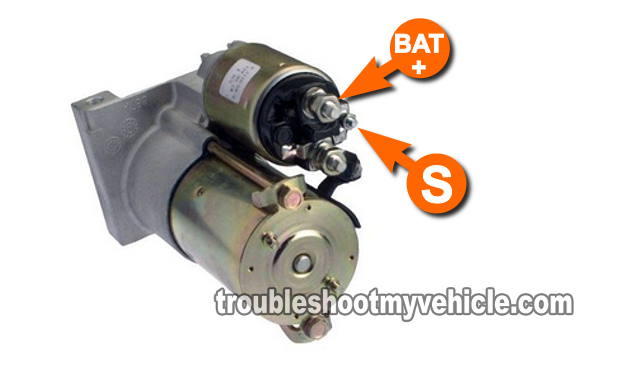

Now, at the starter motor solenoid, place the black multimeter test lead on the stud that connects to the positive (+) battery cable.

The orange arrow labeled BAT+ in the photo above points to this stud. Maintain the black multimeter test lead in this position throughout the next step. - 4

When everything is ready, have your helper crank the engine while you observe the multimeter.

Although the starter motor won't crank the engine, your helper has to turn the ignition switch to START the engine for the voltage drop test to work. - 5

If everything is OK (no voltage drop), the multimeter will register 0.5 Volts or less (0.5 V is really 0 Volts).

If there's a voltage drop problem in this wire, your multimeter will register some voltage, usually 5 Volts or above.

OK, now that the testing part is done, let's take a look at what your results mean:

CASE 1: Your multimeter indicated NO voltage drop (which is 0.5 Volts or less). This result indicates that the starter motor is receiving all of the battery voltage and amperage it needs to crank the vehicle.

This result also confirms that the starter motor is bad and needs to be replaced if you have:

- Confirmed that the ignition switch and the neutral safety switch are good and that the starter is getting the crank signal (STARTER TEST 1).

- Confirmed that the starter motor did not crank the engine when you applied 12 Volts to the S terminal of the starter motor solenoid (STARTER TEST 2).

- Confirmed that the starter is getting all of the power it would need to crank the engine (this test section).

Now, before you remove the starter motor, do two more things.

1.) Turn the engine manually (using a 1/2 ratchet and the appropriate socket). This will verify that the engine is not mechanically locked up.

2.) Bench test the starter motor. You can find the step-by-step instructions here: How To Bench Test A Starter Motor (Step By Step) (at: easyautodiagnostics.com).

CASE 2: Your multimeter registered 5 Volts or more. This result tells you that a voltage drop does exist and this voltage drop is not a good thing to have in this circuit.

The solution is to simply disconnect the positive (+) battery cable from the battery and thoroughly clean it. Also, the end of this very same cable, that's attached to the starter motor solenoid, should be disconnected, inspected and cleaned.

Cleaning the end that attaches to the starter motor solenoid should be done with a small piece of sand paper. Once both ends of the battery positive cable are clean, reconnect everything and try cranking the car. If the voltage drop was the cause of the no-crank condition, your vehicle will now crank and start.

Related Test Articles

I have written quite a few articles on the GM 3.8L equipped cars to help you solve the most common types of problems with specific troubleshooting tests. You can find the ones I've written for this site, by checking out the following index of articles: GM 3.8L Index Of Articles.

Here's a sample of the tutorials you'll find:

- How To Do An Engine Compression Test (GM 3.8L).

- How To Test A Blown Head Gasket (GM 3.8L).

- How To Diagnose Misfire Codes P0300-P0306 (GM 3.8L).

- How To Test The Ignition Coil Packs (at: easyautodiagnostics.com).

- How To Test The Ignition Control Module (at: easyautodiagnostics.com).

- How To Test The MAF Sensor (at: easyautodiagnostics.com).

If this info saved the day, buy me a beer!