If you're trying to nail down a hard to diagnose misfire condition or misfire codes and need to know how to do and interpret an engine compression test, you've come to the right article.

This tutorial will walk you thru' the engine compression tests as it pertains to troubleshooting a misfire condition that is lighting up the check engine light (and storing any of the misfire codes: P0300, P0301, P0302, P0303, P0304, P0305, P0306).

You'll also be able to find out if a compression problem is causing an engine no-start problem.

Contents of this tutorial:

ES ![]() You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (GM 3.1L, 3.4L) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (GM 3.1L, 3.4L) (at: autotecnico-online.com).

Tools You'll Need:

- Compression Gauge Tester

- Engine Oil

- A Helper

- Pen and Paper

Symptoms Of Low Or No Compression

Generally, when an engine compression issue rears it head in your vehicle's engine, it'll usually cause one of two major issues:

- Low Compression In Some But Not All Cylinders: This means that certain cylinders in the engine are not generating the proper amount of compression. This can happen due to various reasons such as worn piston rings, leaking valves, or a blown head gasket.

- Zero PSI Compression In Some Or All Cylinders: This indicates a severe issue where either some or all cylinders are failing to generate any compression at all. This could be caused by catastrophic failures like a cracked engine block, severely damaged piston rings, or a complete valve failure.

Regardless of whether the compression issue is low or zero, you'll notice several symptoms that affect the engine's performance and drivability:

- Hard Starting Or No Start: This happens because the engine struggles to generate enough compression to ignite the fuel-air mixture for combustion.

- Poor Engine Performance: Due to incomplete combustion or loss of power from cylinders with low or no compression.

- Misfiring: When cylinders don't produce enough compression, it can lead to misfires as the fuel-air mixture doesn't ignite properly.

- Reduced Power And Performance: Lack of proper compression means the engine won't be able to deliver the expected power output.

- Excessive Oil Consumption: If the piston rings are worn or damaged, oil can leak into the combustion chamber, leading to increased oil consumption.

- Audible Engine Noise: Issues like valve leaks or worn piston rings can cause abnormal noises such as ticking or knocking from the engine.

In OBD II equipped vehicles (1996+), you might see specific trouble codes related to these issues:

- P0301: Random Cylinder Misfire.

- P0302: Cylinder Number 2 Misfire.

- P0303: Cylinder Number 3 Misfire.

- P0304: Cylinder Number 4 Misfire.

- P0305: Cylinder Number 5 Misfire.

- P0306: Cylinder Number 6 Misfire.

Why An Engine Compression Test?

An engine compression test is one of the most important tests to perform when trying to solve a hard to diagnose misfire condition (or a rough idle condition).

If only one cylinder has below average compression (compared to the other 5 cylinders), that cylinder will not contribute to engine power and you're gonna' feel it.

Also, no matter what you replace, the misfire condition or misfire codes (P0300, P0301, P0302, P303, P0304, P0305, P0306) will not go away! Unfortunately, the engine compression test is one of the most overlooked misfire troubleshooting tests.

Now, testing the compression of each cylinder is usually done after verifying that each cylinder is getting spark. At the end of this article, you'll find another test article (GM 3.1L and 3.4L specific test article) that'll help you to further test a misfire condition.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make these recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Dry Engine Compression Test

Testing the engine compression of the 3 cylinders that face the firewall of your 3.1L or 3.4L GM car or mini-van (Chevrolet, Buick, Oldsmobile, or Pontiac) can be quite a challenge, since removing those spark plugs is not the easiest thing in the world.

In most cases the alternator has to be removed to gain access to them. If you've never removed these spark plugs from your vehicle, I recommend buying a repair manual to brush up on the steps to do it.

NOTE: If possible, the engine should be slightly warmed up for this test, yet it can not be hot (technically: normal operating temperature) So, if the engine is completely cold, start her up and let it idle for no more than 10 minutes. If the engine has been running for a long period of time, let her cool down for about 1 hour.

OK, here's the test:

- 1

Disable the fuel and ignition system. It's important that no fuel is being injected and that no spark is being fired when doing this test.

You can easily kill these two birds with one stone by disconnecting all three of the ignition control module electrical connectors. - 2

Remove all of the six spark plugs.

Be careful and don't drop any of the spark plugs. Dropping them could cause their Ceramic Insulator to break and this will cause a misfire.

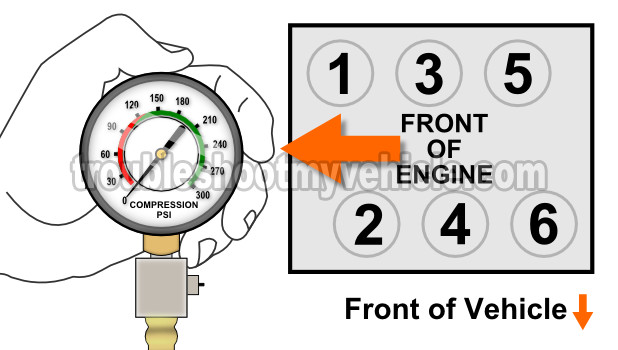

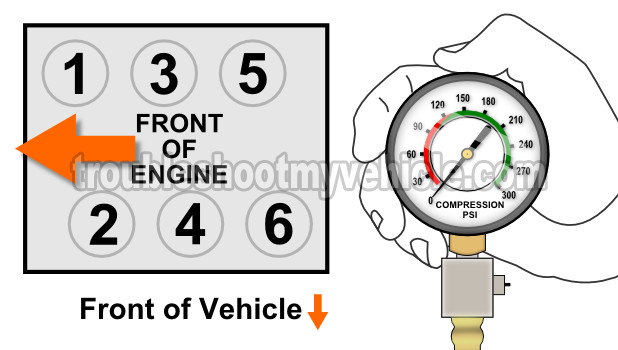

IMPORTANT: Before disconnecting the spark plug wires, to remove the spark plugs, tag each one to identify where it goes. This will help you to connect the right spark plug wire to the right spark plug once you're done with the test. - 3

Hand-thread the engine compression gauge into the spark plug hole that you've chosen to test first.

Do not use any type of tool to get it tight, hand tight is enough! - 4

Once everything is set, have your helper crank the car or mini-van.

- 5

Once the needle on the compression tester gauge stops climbing, have your helper stop cranking the engine.

It normally takes about 10 seconds or engine cranking to get to this point. When the needle stops moving, you have reached the maximum compression pressure of that cylinder. - 6

Record the reading on a piece of paper along with the cylinder the reading belongs to.

- 7

Repeat this exact same test on the remaining engine cylinders. The illustration above will help you to identify what cylinders you're testing.

Let's take a look at what your test results mean:

CASE 1: No compression in 2 or more cylinders. This test result tells you that the engine has serious internal problems.

The most common issues would be: Broken timing chain. Or a blown head gasket. Or the engine threw a rod. To test for a blown head gasket, see this tutorial: How To Test A Blown Head Gasket (GM 3.1L, 3.4L).

CASE 2: Low compression in one or more cylinders. To a certain point, it's normal for the compression to vary a little between cylinders (as the engine accumulates thousands of miles). But if these values vary too much, then you're gonna' have a bonafide misfire on your hands.

So, your next step is to do the math and find out if these compression values are within normal parameter or not. Go to: Interpreting Your Compression Test Results.

Interpreting Your Compression Test Results

Low compression readings, in one or more engine cylinders, are to be expected (especially in high mileage vehicles).

Under a certain threshold, low compression values do not cause any adverse effects on engine performance.

It's when the compression value or values differ more than 15 percent of the highest compression value that they'll cause a problem.

Why? Because if the low compression value varies by more than 15%, then this cylinder is going to misfire and can be considered 'dead'.

You can do this one of two ways: You can calculate this 15% difference with pen and paper or you can use my low compression calculator. You can find the low compression calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that vehicle produced the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 160 PSI |

| #6 | 165 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Compression Test.

TEST 2: Wet Compression Test

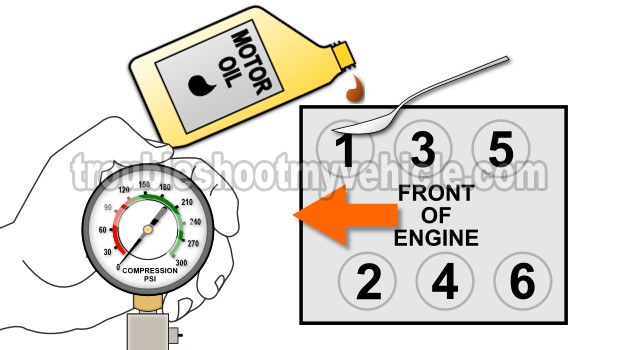

If your compression test confirmed that you've got one or several cylinders with low compression, the next step is to do a 'wet' compression test.

The 'wet' compression test will help you find out if the low cylinder compression is due to worn out cylinder head valves or worn out piston rings.

This is a very simple test that involves adding about 2 tablespoons of oil to the cylinder (that recorded no or low compression in the previous test) and then checking its compression once again.

What will happen is that if the low compression values is due to worn piston rings, the compression value will go up from the previous one you got doing the Dry compression value.

If the compression value does not go up (from the previous one), then you'll know that the problem lies in the cylinder head valves.

OK, to get this pot of water boiling, this is what you need to do:

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the 'Dry' compression test

The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder.

Do not use any type of tool to tightened the compression tester. Hand tight is fine. - 3

When all is set up, have your helper crank the engine.

- 4

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before).

2.) The compression value will stay the same.

Let's analyze your test results:

CASE 1: The compression value shot up. This tells you that the Piston Compression Rings are worn out and thus the problem is in the bottom end.

The reason why the compression value shot up, with the engine oil added, is because the oil is aiding the piston rings to create a near perfect seal.

Since the oil is not letting the compression escape by the rings, this results in your compression gauge reading a higher value than with the 'dry' compression test.

CASE 2: The compression value stayed the same. This confirms that the problem is in the cylinder head valves.

The reason why the compression reading did not shoot up, is because the engine oil can not help the intake or exhaust valve seal the compressed air. Therefore, the compression value will stay the same.

Related Test Articles

If the engine compression test, you just got done doing, indicates that all engine cylinders have healthy compression, and your 3.1L or 3.4L equipped GM (Chevrolet, Buick, Olds, Pontiac) car or mini-van is still misfiring, the following articles might help:

- How To Test The Ignition Coil Packs (GM 3.1L, 3.4L) This tutorial will help you to troubleshoot the ignition coil packs, spark plug wires, ICM, etc. (at: easyautodiagnostics.com).

- How To Do A Cylinder Balance Test (GM 3.1L, 3.4L).

- How To Troubleshoot Misfire Codes (GM 3.1L, 3.4L)

- How To Do A Fuel Injector Resistance Test (GM 3.1L, 3.4L)

If this info saved the day, buy me a beer!