You can quickly and accurately test the alternator with a simple multimeter -no expensive diagnostic equipment is needed!

In this tutorial, you'll find the alternator test explained comprehensively and step-by-step.

Contents of this tutorial:

- Important Testing Tips.

- Symptoms Of A Bad Alternator.

- TEST 1: Checking Alternator Voltage Output With A Multimeter.

- TEST 2: Testing The Continuity Of The Alternator's Output Wire.

- TEST 3: Checking The Battery Voltage Sense Circuit Wire.

- TEST 4: Making Sure The ALT Fuse Is Not Blown.

- More 3.1L Buick Regal And Oldsmobile Cutlass Supreme Test Tutorials.

ES ![]() You can find this tutorial in Spanish here: Cómo Probar El Alternador (1989-1993 3.1L Buick Regal, Oldsmobile Cutlass Supreme) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Alternador (1989-1993 3.1L Buick Regal, Oldsmobile Cutlass Supreme) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 3.1L Buick Regal: 1989, 1990, 1991, 1992, 1993.

- 3.1L Oldsmobile Cutlass Supreme: 1989, 1990, 1991, 1992, 1993.

Important Testing Tips

TIP 1: The battery must be fully charged before starting TEST 1 of this tutorial.

TIP 2: You can use a digital multimeter or an analog multimeter.

TIP 3: Take all necessary safety precautions. Be alert and think safety all of the time since you'll be working around a running engine.

Symptoms Of A Bad Alternator

As you're already aware, the battery discharges every time you start the engine.

It's the alternator's job to recharge the battery once the engine starts.

The alternator also provides all the electrical current (amperage) and voltage the accessories need when the engine is running.

Sooner or later, the alternator will fail, and when it does, it simply stops charging the battery.

When the alternator fails, you'll see one or more of the following symptoms:

- The charge light (also known as the battery light) will be shining nice and bright on your vehicle's instrument cluster.

- Whenever you turn on the headlights (night driving), they glow very dim.

- The car won't crank. It will only crank and start if you jump start your vehicle.

- The only way the car cranks and starts is if you charge the battery.

TEST 1: Checking Alternator Voltage Output With A Multimeter

The first order of business will be to check the battery's voltage with the engine running.

If the alternator is charging the battery, you should see a battery voltage between 13.5 to 14.5 Volts DC.

If the alternator is not charging the battery, you'll see a battery voltage of 12.5 Volts, which will decrease the longer the engine stays running.

If the battery voltage is 12.5 Volts or less, the alternator is not charging the battery, and we'll move on to the next test.

Let's get started:

- 1

Start the engine and let it idle.

- 2

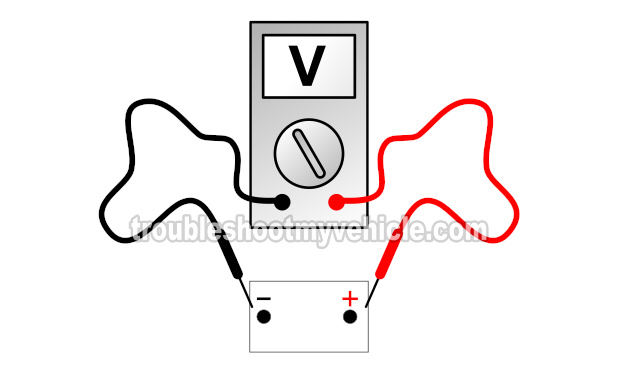

Place your multimeter in Volts DC mode.

- 3

Check the battery's voltage with your multimeter.

- 4

The multimeter should register 13.5 to 14.5 Volts.

If it doesn't, don't worry about this just yet, continue to the next step. - 5

Turn on every accessory possible while observing the multimeter. Like the headlights, the A/C or heater (high blower speed), the windshield wipers, the radio, the rear window defroster, etc.

As each accessory comes on, they'll place a load on the charging system (alternator). - 6

As each accessory comes on, your multimeter will do one of two things:

1.) The multimeter's voltage reading will decrease slightly and then stabilize around 13.5 to 14.5 Volts DC (when something comes on).

2.) The DC voltage reading will decrease to 10 Volts DC.

Let's analyze your multimeter test results:

CASE 1: The multimeter maintained a 13.5 to 14.5 Volts value thru' out the whole test. This test result confirms the alternator is functioning correctly.

Since the alternator is charging the battery, no further testing is required.

CASE 2: The multimeter DID NOT maintain a 13.5 to 14.5 Volts value. This test result confirms the alternator is not charging the battery.

The next step is to test the continuity of the wire connecting the alternator to the battery. For this test go to: TEST 2: Testing The Continuity Of The Alternator's Output Wire.

TEST 2: Testing The Continuity Of The Alternator's Output Wire

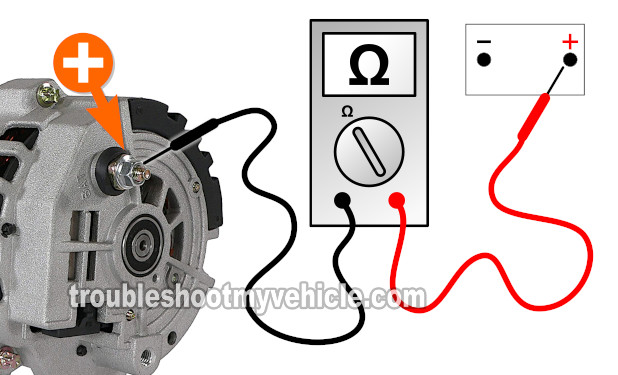

All the alternator's output is delivered to the battery by the cable connecting to the rear of the alternator.

If you look at the rear of your vehicle's alternator, you'll see a cable attached to a stud (with a nut).

I've labeled this stud with the orange arrow with the '+' symbol in the image above.

An inline fusible link protects the alternator's battery cable, and we'll check that it isn't blown by doing a simple multimeter continuity test (on the cable).

If the cable has continuity between the battery positive (+) post and the alternator, the inline fusible link is OK, and we'll move on to TEST 3.

NOTE: Do not disconnect the cable from the BAT stud. In the image above, the alternator is shown off of the vehicle to facilitate the multimeter test connections.

OK, let's get started:

- 1

Disconnect the battery negative (-) cable from the battery but leave the positive (+) cable connected to the positive (+) post.

IMPORTANT: Do not proceed to the next steps until you do this first. - 2

Set your multimeter to Ohms mode.

- 3

Connect the red multimeter test lead to the stud shown in the photo above.

The alternator's output wire connects to the stud the arrow points to (in the photo above). - 4

Connect the black multimeter test lead on the battery positive (+) terminal (at the battery).

The battery negative (-) wire must remain disconnected from the battery. - 5

Your multimeter will register one of two values:

1.) Continuity (usually an Ohms value of about 0.5 Ohms).

2.) No continuity (an infinite Ohms reading (OL)).

OK, let's interpret your test results:

CASE 1: Your multimeter registered continuity (usually 0.5 Ohms). This is the correct and expected test result and confirms the inline fusible link (protecting the alternator's output cable) is OK.

So far, it's looking like the alternator is bad. Let's move on to the next test: TEST 3: Checking The Battery Voltage Sense Circuit Wire.

CASE 2: Your multimeter DID NOT register continuity, it registered OL. This test result confirms the inline fusible link protecting this wire is blown.

Your next step is to replace the inline fusible link and retest.