Testing testing the throttle position sensor (TPS) on your 2.4L Honda Accord isn't difficult at all. And you don't need any expensive diagnostic equipment to do it!

In this tutorial, I'm gonna explain how to test it with a multimeter. With your test results, you'll be able to quickly find out if the TPS is functioning correctly or if it's bad.

All of the test steps are explained in a step-by-step manner so that you can quickly diagnose the throttle position sensor on your Honda Accord.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Honda Accord: 2003, 2004, 2005.

Symptoms Of A Bad Throttle Position Sensor

The throttle position sensor is a critical component of the engine management system. So when it fails, you'll definitely notice that something is wrong.

You'll see one of the following OBD II TPS diagnostic trouble codes illuminating the check engine light:

- P0122: Throttle Position Sensor Circuit Low Input.

- P0123: Throttle Position Sensor Circuit High Input.

- P1121: Throttle Position Sensor Signal Lower Than Expected.

- P1122: Throttle Position Sensor Signal Higher Than Expected.

You're also going to see one or more of the following symptoms:

- Engine hesitates when you step on the accelerator pedal.

- Lack of power when accelerating the vehicle.

- Bad gas mileage.

- Engine idle either too high or too low.

- Rough engine idle.

- The engine may start and immediately stall.

- The engine cranks but does not start.

Throttle Position Sensor (TPS) Circuit Descriptions

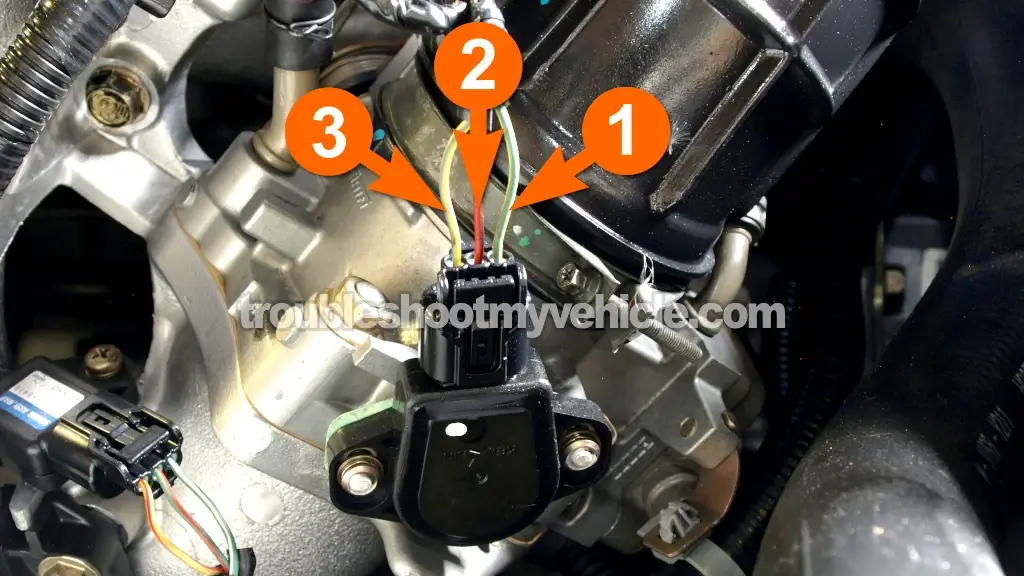

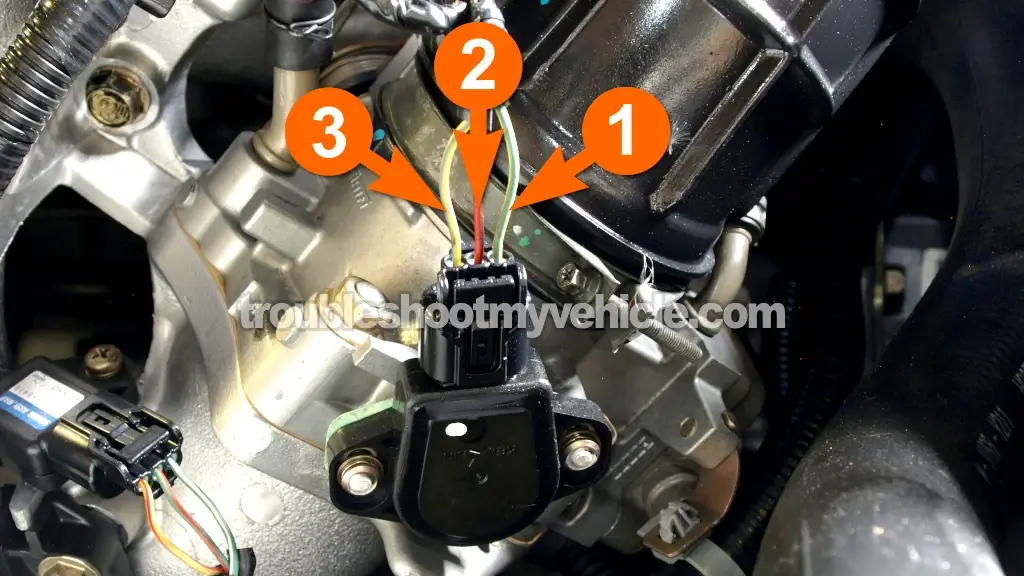

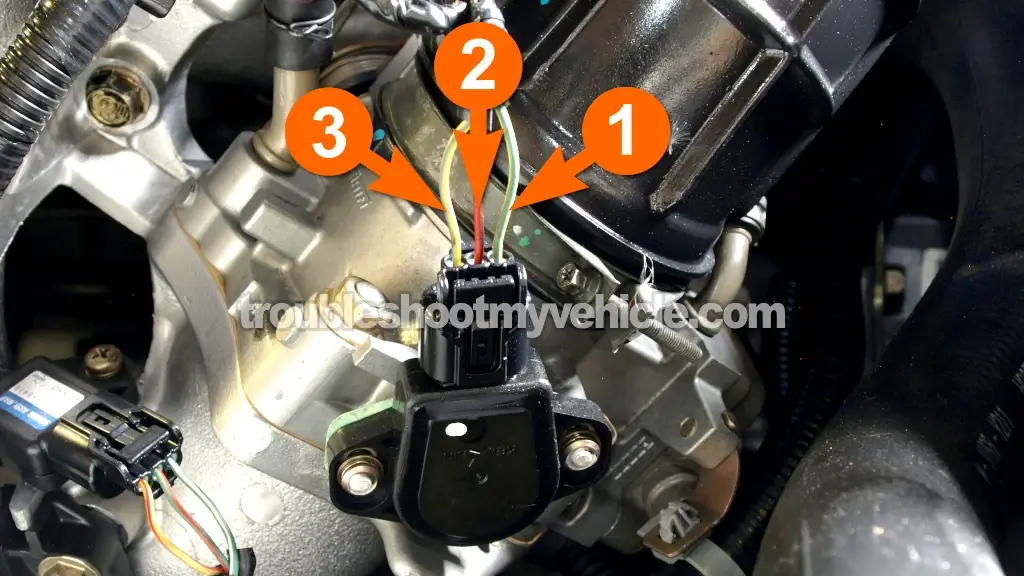

I'm sure you've already noticed that the throttle position sensor has three wires coming out of its pigtail connector.

Each wire has a specific role, and the table below gives a brief description of each:

| Terminal | Wire | Description |

|---|---|---|

| 1 | Green with yellow stripe (GRN/YEL) | Ground (from PCM) |

| 2 | Red with black stripe (RED/BLK) | TPS Signal |

| 3 | Yellow with blue stripe (YEL/BLU) | 5 Volts (from PCM) |

Where To Buy The TPS And Save

The following links will help you comparison shop for the throttle position sensor (of known professional automotive brands- NO knock-offs):

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Testing The TPS Voltage Signal

The very first thing that we're going to do to get our TPS diagnostic started, is to check the performance of the TP sensor.

This test involves connecting the multimeter to the TP sensor signal wire and checking to see if the signal increases/decreases as we open/close the throttle plate.

Right off the bat, this test will let us know if the throttle position sensor is functioning correctly or if it's having problems.

The wire that we're going to tap into to read the TP voltage signal is the one that I've labeled with the number 2 in the photo above. This wire is the red with black stripe (RED/BLK) wire of the connector.

IMPORTANT: The throttle position sensor must remain connected to its connector in order to access the signal in the wire. You'll need to use a back-probe on the connector or a wire-piercing probe on the wire. You can see what this tool looks like and where to buy it here: Wire Piercing Probe.

Let's get started:

- 1

Place your multimeter in Volts DC mode.

- 2

Connect the red multimeter test lead to the red with black stripe (RED/BLK) wire of the TP sensor harness connector.

I've labeled the RED/BLK wire with the number 2 in the photo above.

NOTE: The TPS must remain connected to its connector to test the TPS voltage signal. - 3

Connect the black multimeter test lead directly on the battery negative (-) post.

- 4

Turn the key on but don't crank or start the engine.

- 5

Manually rotate the throttle plate to its open position.

You'll get the best results by opening and closing the throttle plate directly on the throttle body instead of stepping on the accelerator pedal. - 6

The multimeter should show an increasing voltage as you (or your helper) open up the throttle plate.

- 7

Close the throttle plate as you observer the multimeter.

- 8

The multimeter should show a decreasing voltage as you begin to close the throttle plate.

- 9

Using a screwdriver's handle, gently tap the TP sensor as you open and close the throttle plate and observe the multimeter.

The purpose (of tapping the TP sensor with the screwdriver's handle) is to see if the TP sensor shows gaps in the voltage signal. Why? Because a good TP sensor will show a continuous increasing or decreasing voltage signal even while getting tapped by the screw-driver's handle.

Let's analyze your test results:

CASE 1: The TPS voltage signal increased/decreased as you opened/closed the throttle plate. This is the correct test result and it indicates that the throttle position sensor is good.

With this test result you can also conclude that the TPS sensor is getting both power (5 Volts) and Ground from the fuel injection computer.

CASE 2: The TPS voltage signal DID NOT increase/decrease as you opened and closed the throttle plate. This test result usually indicates that the TPS sensor is defective.

To make sure the TPS sensor is bad the next step is to check that the YEL/BLU wire is feeding the TPS with 5 Volts. For this test go to: TEST 2: Making Sure The TPS Is Receiving 5 Volts.

CASE 3: The multimeter DID NOT register any voltage. This test result usually indicates that the TPS sensor is defective.

To make sure the TPS sensor is bad the next step is to check that the YEL/BLU wire is feeding the TPS with 5 Volts. For this test go to: TEST 2: Making Sure The TPS Is Receiving 5 Volts.