When it comes to chasing down a tough-to-solve misfire or an engine that just won't start, a compression test is one of the most valuable tests you can run.

In this tutorial, I'll walk you through the steps of performing a compression test on the 1999–2007 4.7L V8 Jeep Grand Cherokee, and just as important, I'll show you how to make sense of the numbers you get.

Armed with these results, you'll know right away if low or uneven compression is the reason behind a cylinder misfire or an engine no-start condition.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 4.7L V8 Jeep Grand Cherokee: 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007.

Symptoms Of Engine Compression Problems

Engine compression issues usually show up in one of two ways:

- No-start condition: Low or 0 PSI compression in most or all cylinders keeps the engine from firing up at all.

- Misfire/rough idle: The engine will start and run, but one or more cylinders are weak, and that shows up as a misfire or rough idle.

If the engine starts and runs, a compression-related misfire will usually trigger one or more of the following cylinder misfire trouble codes:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

- P0307: Cylinder #7 Misfire.

- P0308: Cylinder #8 Misfire.

You may also notice other symptoms alongside the codes:

- Rough idle only at low RPM: At idle, the engine shakes. Once you rev it up, the problem smooths out because the low compression cylinder isn't as noticeable at higher RPM speeds.

- Poor fuel economy: Since one or more cylinders aren't pulling their weight, the engine burns more fuel to do the same work.

- Strong exhaust odor: Unburned fuel makes its way into the exhaust, producing a heavier smell out of the tailpipe.

Important Tips

Before you jump into the compression test on your 4.7L Grand Cherokee, keep these safety and setup tips in mind:

TIP 1: You'll be working close to a cranking engine, so stay alert and use the same caution you would with any moving parts.

TIP 2: If the engine was recently running, give it plenty of time to cool down before pulling the spark plugs. Removing them from a hot cylinder head can lead to burns or damaged threads.

TIP 3: When threading in the compression tester, snug it in by hand only. Avoid using pliers or a wrench—you don't want to strip or damage the spark plug threads.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make three recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Dry Engine Compression Test

Every cylinder in the 4.7L V8 needs three things to fire: spark, fuel, and air. If any of these are missing, that cylinder is going to misfire. But what often gets overlooked during diagnosis is the cylinder's own mechanical health. That's where a simple compression test comes in.

Here's how to do it step by step:

- 1

Disable the fuel system by pulling the ASD relay or by unplugging all 8 fuel injectors from their connectors.

- 2

Disable the ignition system. You don't want spark jumping while cranking.

On the 4.7L, you can do this by disconnecting the coil packs. - 3

Remove all 8 spark plugs.

Take your time and don't drop them. A cracked ceramic insulator will give you a new misfire that wasn't there before. - 4

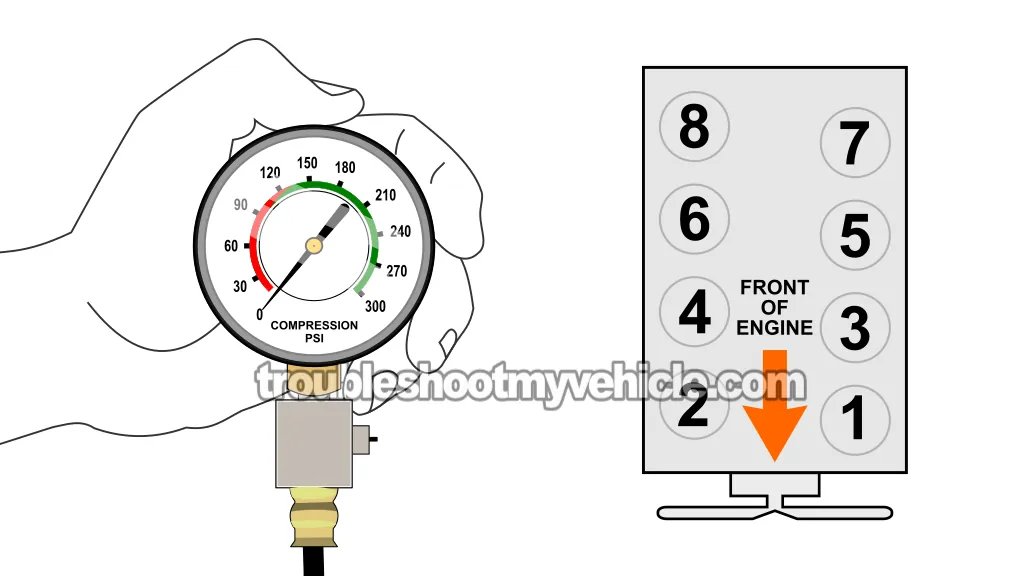

Thread the compression tester into the #1 spark plug hole (this is the front cylinder on the passenger side).

Hand tighten the tester only—no tools. - 5

Have a helper crank the engine (or use a remote starter switch) while you keep your eyes on the gauge.

- 6

When the needle stops climbing, stop cranking and note the reading.

- 7

Record the reading and cylinder number so you don't lose track.

- 8

Repeat the test on the remaining 7 cylinders.

Once you've got all 8 numbers written down, here's how to read them:

CASE 1: Two or more cylinders show little to no compression. This usually points to a major internal failure such as:

- Blown head gasket.

- Timing chain failure.

- Thrown connecting rod.

CASE 2: One or two cylinders show noticeably lower compression. Some variation is normal, but if the spread is too wide, the engine will misfire.

The next step is to run the numbers and see if the lowest reading is still within spec compared to the highest one. Head over to: Interpreting Your Compression Test Results.

Interpreting Your Compression Test Results

On a high-mileage 4.7L engine, it's completely normal to see that some cylinders produce lower compression readings than others.

If the difference between the lowest and highest readings is small, your Jeep's 4.7L V8 will usually keep running without any noticeable drivability issues.

But once that difference gets too large, the engine will start showing signs like a rough idle or a cylinder misfire.

The good news is that you don't have to guess whether the difference is acceptable or not —there's a simple way to find out.

All you need to do is figure out if the lowest reading is more than 15% below the highest reading. If it is, then the cylinder (or cylinders) with the low compression are causing the problem.

You can calculate this 15% by hand, or you can use my online calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to crunch the numbers yourself, here's how:

- STEP 1: Take the highest compression reading you got and multiply it by 0.15 (15% in decimal form).

- STEP 2: Round the result to the nearest whole number.

- STEP 3: Subtract that rounded number from the highest compression reading.

- ANSWER: The final number is the minimum acceptable compression value. Any cylinder reading below this number indicates a problem.

Let me show you what I mean with a real example: Let's say these were my compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 165 PSI |

| #6 | 170 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, it's safe to say that this cylinder is 'dead' and responsible for the misfire.

To check if one of your cylinders is also out of range, just run the same calculation using the highest reading you got from your own engine compression test (don't use the numbers in my example).

Once you've pinpointed the weak or 'dead' cylinder, the next step is to figure out why it's showing low compression. That's where the following test comes in: TEST 2: Wet Engine Compression Test.

TEST 2: Wet Engine Compression Test

If you're trying to figure out whether the low compression you saw in TEST 1 is being caused by worn piston rings or by worn/damaged cylinder head valves, this next test will give you the answer.

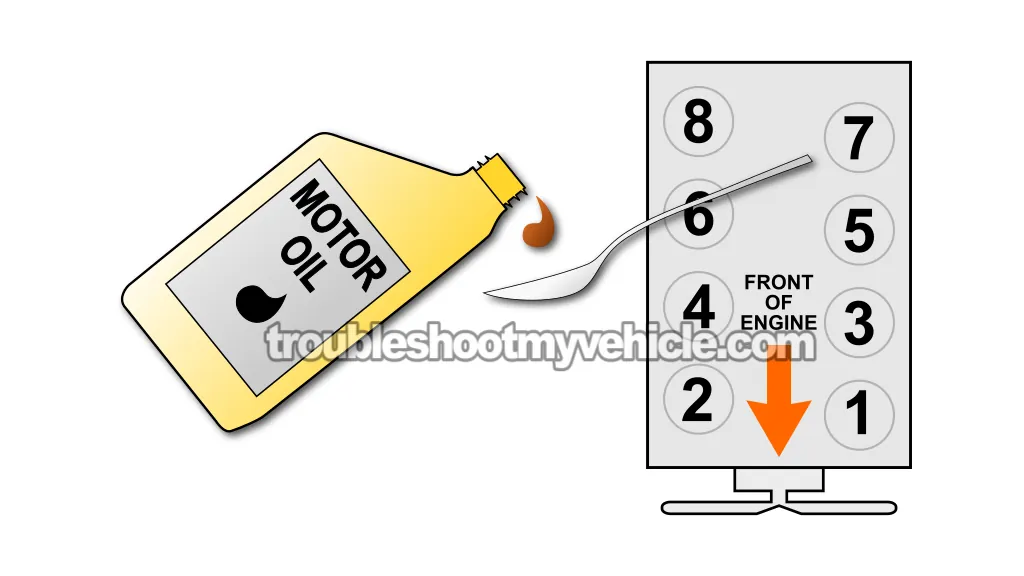

The idea is simple: add about 2 tablespoons of clean engine oil into the cylinder that produced the low reading. This is called a 'wet' compression test.

When you add oil, one of two things will happen:

- Compression goes up: If the PSI increases noticeably, the problem is with worn piston rings.

- No change at all: If the PSI stays the same, the problem lies in the cylinder head valves (burned valves, or worn/damaged valve seats).

Here's how to run the test:

- 1

Pour about 2 tablespoons of engine oil into the cylinder that showed low compression in TEST 1.

- 2

Reinstall the compression gauge and hand-tighten it just like before.

- 3

Crank the engine with your helper's assistance while you watch the gauge.

- 4

When the needle stops moving upward, stop cranking and note the final PSI reading.

- 5

Compare the result:

1.) If the gauge now shows a much higher reading than before, the rings are worn.

2.) If the reading hasn't changed, the issue is with the valves.

CASE 1: PSI goes up after adding oil → Bad piston rings are behind the low compression.

CASE 2: PSI does not change → Worn or damaged cylinder head valves are the cause of the low compression.

More 4.7L V8 Jeep Grand Cherokee Diagnostic Tutorials

If you'd like to check out more step-by-step diagnostic guides, I've put together a complete list of Jeep 4.7L V8 Grand Cherokee tutorials here:

In that section, you'll find several hands-on test tutorials. Here are just a few examples:

If this info saved the day, buy me a beer!