Interpreting Your Compression Test Results

Over time, wear and tear can cause variations in compression between the cylinders of your Toyota’s engine.

- Minor differences: Small variations in compression values are normal and typically don’t affect engine performance.

- Significant differences: Larger variations can lead to issues like a rough idle or misfire.

To figure out if a lower compression value is problematic, compare it to the highest value recorded. If the difference is greater than 15%, it could be the root cause of your engine’s rough performance.

Two ways to calculate the 15% difference:

- Manual Calculation: Use pen and paper to determine if a cylinder’s compression value is more than 15% lower than the highest recorded value.

- Low Compression Calculator: Simplify the process with my low compression calculator, which you can access here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that I got the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Engine Compression Test.

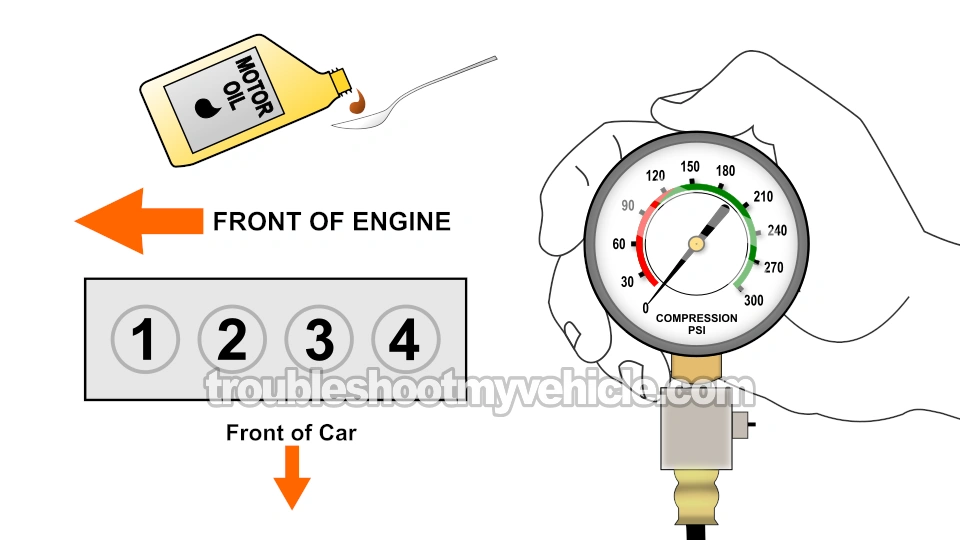

TEST 2: Wet Compression Test

If your compression test (TEST 1) revealed a cylinder with a value more than 15% lower than the highest recorded value, the next step is to determine whether the issue stems from severe wear or damage to the piston rings or cylinder head valves.

A ‘wet’ compression test can help pinpoint the cause:

- Add a small amount of engine oil to the affected cylinder.

- Retest the cylinder’s compression.

Interpreting the Results

- Compression value increases: If the compression improves with oil, the issue is likely due to worn piston rings.

- Compression value stays the same: If there’s no change, the problem is likely with the cylinder head valves.

These are the test steps:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest.

I suggest using a small and long funnel so that the oil will reach the inside of the cylinder. - 2

Once you've added the oil, install the compression gauge, and as before just hand tighten it.

- 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

A.) The needle will climb higher than the previous compression number you recorded for this specific cylinder.

B.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

If you have another cylinder that needs to be tested, then repeat steps 1 thru' 4 on it now.

Let's take a look at what test results mean:

CASE 1: The compression value went up after adding motor oil and retesting. This tells you that the low compression problem is due to worn piston compression rings.

Here's why: The motor oil you just added helped the piston rings to create a tighter seal. With the piston rings now sealing the compression inside the cylinder, the compression value on your compression tester went up. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: The compression value DID NOT go up after adding oil and retesting (in other words, it stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

More 2.0L Toyota Camry Tutorials

You can find a complete list of 2.0L Toyota Camry tutorials and wiring diagrams in this index:

Here's a sample of the tutorials you'll find there:

- TPS Idle Switch Multimeter Test w/ Automatic Transaxle (1987-1991 2.0L Toyota Camry).

- How To Test The TPS w/ Automatic Transaxle (1987-1991 2.0L Toyota Camry).

- How To Test For A Blown Head Gasket (1987-1991 2.0L Toyota Camry).

- How To Test The Engine Compression (1987-1991 2.0L Toyota Camry).

- How To Test The MAF Sensor (1987-1991 2.0L Toyota Camry).

If this info saved the day, buy me a beer!