In this tutorial, I'll show you how to accurately test the throttle position sensor (TPS) with a multimeter.

You'll also be able to diagnose any of the following TP sensor trouble codes that may be lighting up the check engine light (CEL) on your Chrysler vehicle:

- P0120: Throttle Position Sensor (TPS) Circuit.

- P0121: Throttle Position (TP) Sensor Circuit/Range Performance.

Contents of this tutorial:

Basics Of The Throttle Position Sensor (TPS)

In a nutshell, the throttle position sensor's job is to measure and report (to the PCM) the angle of the throttle plate as you step on (and step off) the accelerator pedal.

Your Chrysler vehicle's PCM receives this throttle angle info on the middle wire of the TPS harness connector. The other two provide power and Ground (to the TPS).

In the table below, you'll find a short description of what each wire does:

| 2.0L Chrysler TPS Circuits (1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002) | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | VIO/WHT | 5 Volts |

| 2 | ORG/DK BLU | Throttle Position Signal |

| 3 | BLK/LT BLU | Sensor Ground |

Where To Buy The TPS And Save

You can buy the throttle position sensor for your Chrysler in just about any auto parts store but you'll spend a whole lot more because they mark it up quite a bit.

My suggestion is to buy it online or at least comparison shop to get an idea of how much it costs and how much you can save:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Checking The Throttle Position Sensor (TPS) Signal

The first test we'll do is to check that the throttle position sensor (TPS) is creating a throttle angle signal.

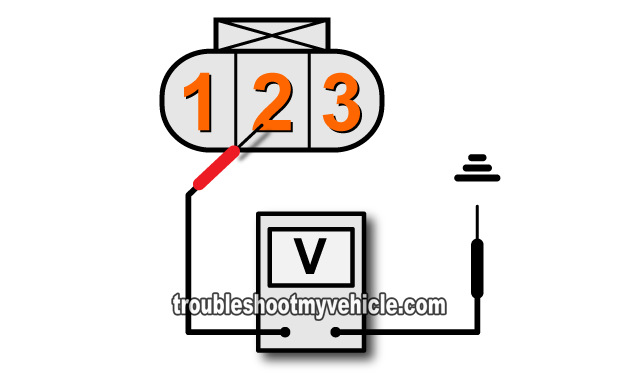

We'll do this by tapping into the orange with dark blue stripe (ORG/DK BLU) wire with your multimeter, then manually opening and closing the throttle plate by hand, and checking the voltages to see if they increase/decrease.

If the TPS is bad, then your multimeter will not register any voltage increases/decreases as you manually open or close the throttle.

IMPORTANT: This is an on car test of the sensor and the throttle position sensor must remain connected to its harness connector.

Here are the test steps:

- 1

Place your multimeter in Volts DC mode and connect the red test lead to the ORG/DK BLU wire of the TP sensor harness connector.

NOTE: The TP sensor connector needs to be connected to the TPS, so you'll need to either back-probe the connector or use a wire piercing probe to get to the signal inside the wire (to see what a wire piercing probe looks like: Wire Piercing Probe Tool). - 2

Ground the black multimeter test lead directly on the battery negative (-) post.

At this point (with the throttle plate closed) your multimeter should read a voltage between 0.3 to 1.0 Volts DC. - 3

Manually rotate the throttle.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 4

The multimeter should show an increasing voltage as you (or your helper) open up the throttle.

With the throttle plate completely open, your multimeter should read: 3.2 to 4.9 Volts DC.

You'll get the best results by opening and closing the throttle directly on the throttle body instead of stepping on the accelerator pedal. - 5

The multimeter should show a decreasing voltage as you begin to close the throttle.

- 6

Using a screwdriver's handle, gently tap the TP sensor as you open and close the throttle and observer the multimeter.

The purpose (of tapping the TP sensor with the screwdriver's handle) is to see if the TP sensor shows gap's in the voltage signal. Why? Because a good TP sensor will show a continuous increasing or decreasing voltage signal even while getting tapped by the screw-driver's handle.

Alright, let's examine your test results:

CASE 1: The TP sensor signal's voltage increased and decreased smoothly and without gaps. This test result confirms that the throttle position sensor (TPS) is OK and not defective.

This test result also tells you that:

- The TPS is getting power on the VIO/WHT wire of its harness connector.

- The TPS is getting Ground on the BLK/LT BLU wire of its harness connector.

CASE 2: The TP sensor signal's voltage did not increase or decrease. In the majority of the cases this TPS result tells you that the sensor is bad. But not always.

To be sure that the TPS is truly fried on your Chrysler vehicle, you need to make sure that it's getting power and Ground. So, to continue with the TPS diagnostic, go to: TEST 2: Making Sure The TPS Is Getting Power.

CASE 3: The TP sensor signal's voltage showed gaps in its voltage output as you tapped the sensor with the screwdriver. If the gaps in the multimeter's voltage readings only showed up when you were tapping on the TPS (with the screwdriver's handle) then this test result tells you that the TPS is bad and needs to be replaced.