In this tutorial, I'm gonna show you how to bench-test the MAP sensor on your 1996–2000 3.3L V6 mini-van.

You only need two things to get started: a multimeter and a vacuum pump. Don't worry if you don't own a vacuum pump —most auto parts stores like AutoZone or O'Reilly Auto Parts will rent you one.

Still can't get a vacuum pump? No problem. You can actually use your your mouth (yep, we'll cover exactly how that works in the steps ahead).

Since all kinds of issues can trick the fuel injection computer (Powertrain Control Module —PCM) into tossing out a MAP sensor code, even when the sensor isn't the real problem. That's why pulling it off the engine and testing it is a smart move. You'll know for sure if it's bad —or if something else is messing with your system.

Contents of this tutorial:

- Symptoms Of A Bad MAP Sensor.

- Where To Buy The MAP Sensor And Save.

- How The MAP Sensor Works.

- TEST 1: Verifying The MAP Signal.

- TEST 2: Making Sure The MAP Sensor Is Getting Power.

- TEST 3: Making Sure The MAP Sensor Is Getting Ground.

- MAP Sensor Code Won't Go Away.

- More 3.3L Chrysler, Dodge, And Plymouth Mini-Van Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.3L V6 Chrysler Town & Country: 1996, 1997, 1998, 1999, 2000.

- 3.3L V6 Chrysler Voyager: 2000.

- 3.3L V6 Chrysler Grand Voyager: 2000.

- 3.3L V6 Dodge Caravan: 1996, 1997, 1998, 1999, 2000.

- 3.3L V6 Dodge Grand Caravan: 1996, 1997, 1998, 1999, 2000.

- 3.3L V6 Plymouth Voyager: 1996, 1997, 1998, 1999, 2000.

- 3.3L V6 Plymouth Grand Voyager: 1996, 1997, 1998, 1999, 2000.

Other MAP Sensor Tests:

- How To Test The MAP Sensor (1991-1995 3.3L V6 Caravan, Grand Caravan, Voyager, Grand Voyager).

- How To Test The MAP Sensor (2001-2004 3.3L V6 Caravan, Grand Caravan, Voyager, Grand Voyager, Town & Country).

Symptoms Of A Bad MAP Sensor

When the manifold absolute pressure (MAP) sensor goes bad, your check engine light's gonna pop on, and you'll see this diagnostic trouble code (DTC) show up:

- P0107: MAP Sensor Circuit – Voltage Too Low.

- P0108: MAP Sensor Circuit – Voltage Too High.

But it's not just about a code showing up. Your 3.3L V6 mini-van's gonna start acting up. You'll notice one —or even a mix— of the following problems:

- Rough idle: The engine shakes or runs uneven when idling.

- Black smoke: Black smoke comes out the exhaust.

- Stalls when you shift into gear: As soon as you drop it into Drive and load the engine, it cuts out.

- Shuts off right after starting: This one a pretty common symptom.

- No power: You'll feel it —try to speed up and the van just doesn't want to move.

MAP sensors do fail all on their own. But plenty of times, something else under the hood messes with the vacuum or the MAP signal, and that's what tricks the PCM into blaming the MAP sensor.

If you wanna be sure the MAP sensor's the real problem —and not just throw parts at the problem —you need to test it. That's what I'm about to show you in this tutorial.

If the sensor passes the test, then you'll wanna check out the section below:

How The MAP Sensor Works

Your 3.3L V6 mini-van uses a "speed density" fuel system. What that means is, there's no mass air flow (MAF) sensor telling the computer how much air the engine's sucking in.

Instead, the PCM figures it all out using:

- The MAP sensor to keep track of engine vacuum,

- The crankshaft position (CKP) sensor to monitor RPMs,

- And the IAT sensor to check the temperature of the air going into the engine.

With these three inputs, the PCM calculates how much air's entering the engine and adjusts fuel accordingly.

Here's what goes down when you turn the key and start the engine:

- The MAP sensor powers up: The PCM sends:

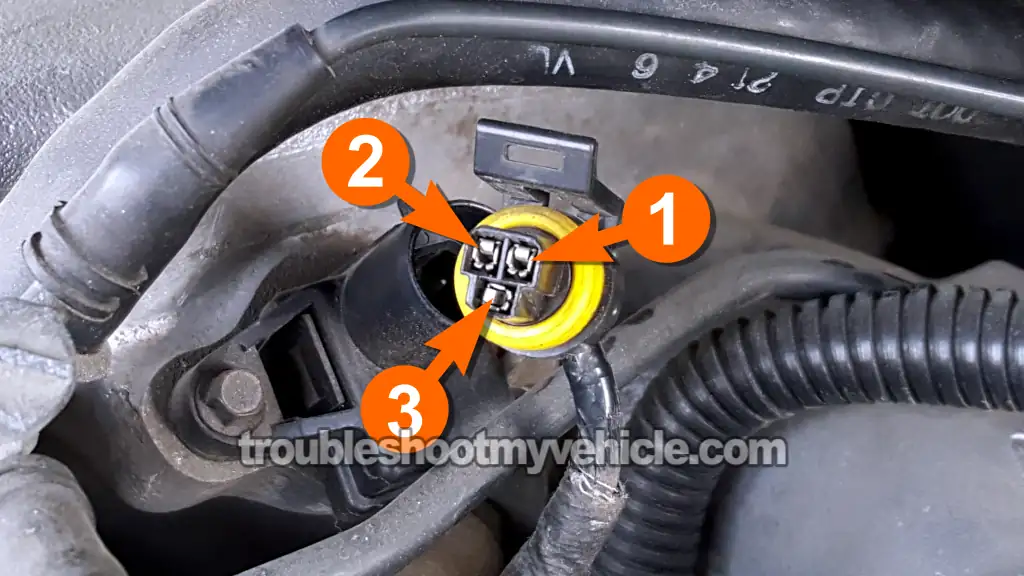

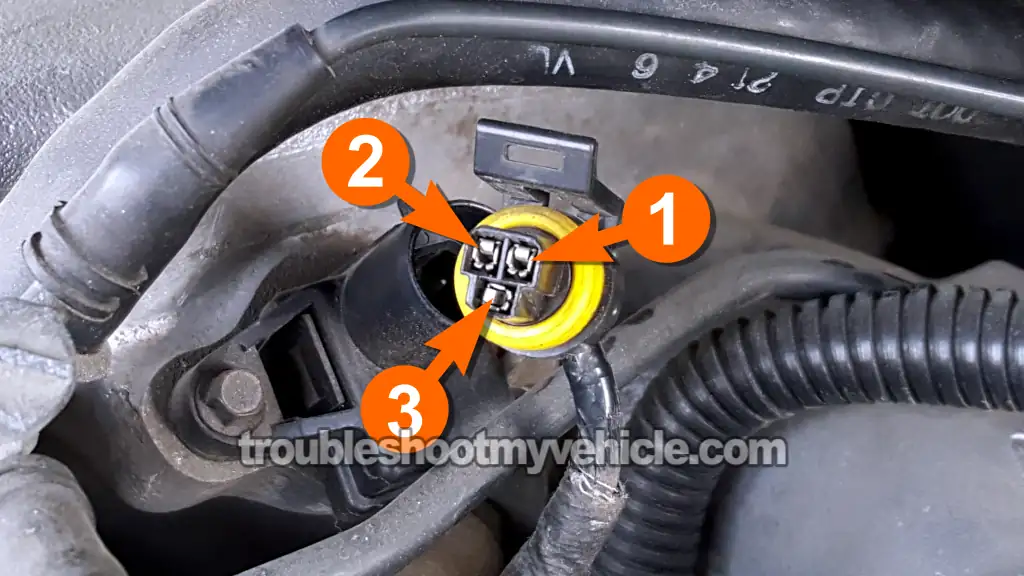

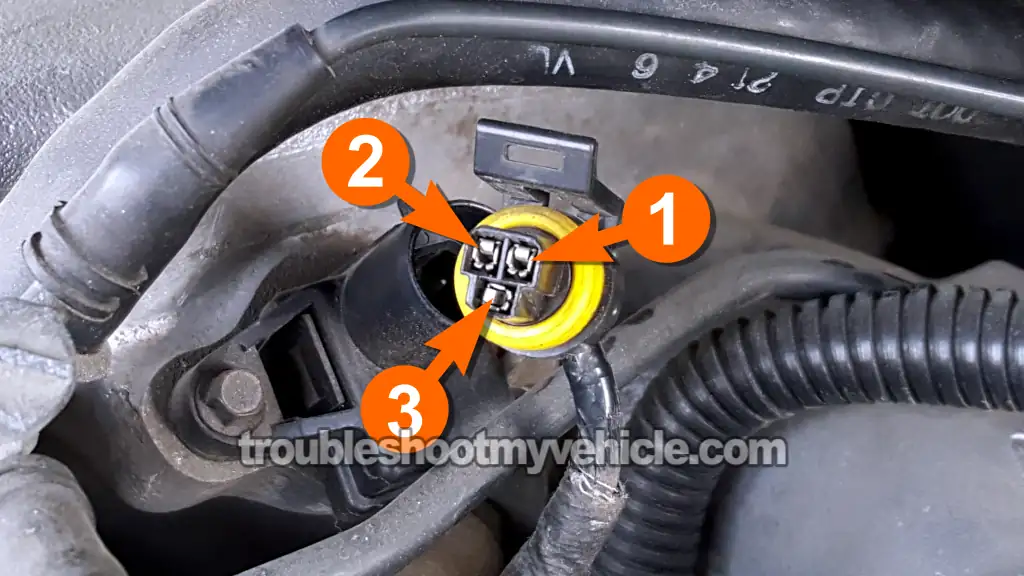

- 5 Volts to female terminal number 2 on the MAP sensor,

- And Ground to female terminal number 1, also from the PCM.

- Measuring vacuum: With power and Ground in place, the MAP sensor starts reading how much vacuum the engine's pulling in.

- Sending the signal: That vacuum info gets sent back to the PCM through the wire on the connector that corresponds to female terminal number 3.

- Fuel system gets to work: The PCM uses all the info from the MAP, IAT, and CKP sensors to calculate the correct air-fuel mix. From there, it:

- Adjusts how long the injectors stay open (that's called pulse width),

- And fine-tunes ignition timing to keep everything running smooth.

The MAP sensor plays a huge role in how well your 3.3L Chrysler, Dodge, or Plymouth mini-van runs. Now that you've got the basics down, let's dive into testing it.

Where To Buy The MAP Sensor And Save

The links below let you compare prices on MAP sensors from trusted name-brand manufacturers —none of that knock-off junk here:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above MAP sensor fits your particular mini-van? Don't worry. Once you get to the site they'll make sure it fits. If it doesn't, they'll find you the right one.

TEST 1: Verifying The MAP Signal

The first thing we're gonna check is whether the MAP sensor can actually put out a changing signal as vacuum is applied to it.

If it's working right, the voltage signal from the sensor should go down when vacuum increases —and climb back up when you let the vacuum go.

But if the MAP sensor's shot, the voltage reading won't move at all, no matter how much vacuum you give it.

NOTE: Need a multimeter or a vacuum pump (or thinking about upgrading)? These are the exact ones I personally use and recommend:

- Multimeter: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

- Vacuum pump: HTOMT 2 In 1 Vacuum Pump Test Set (at: amazon.com).

Alright, here's how to kick things off:

- 1

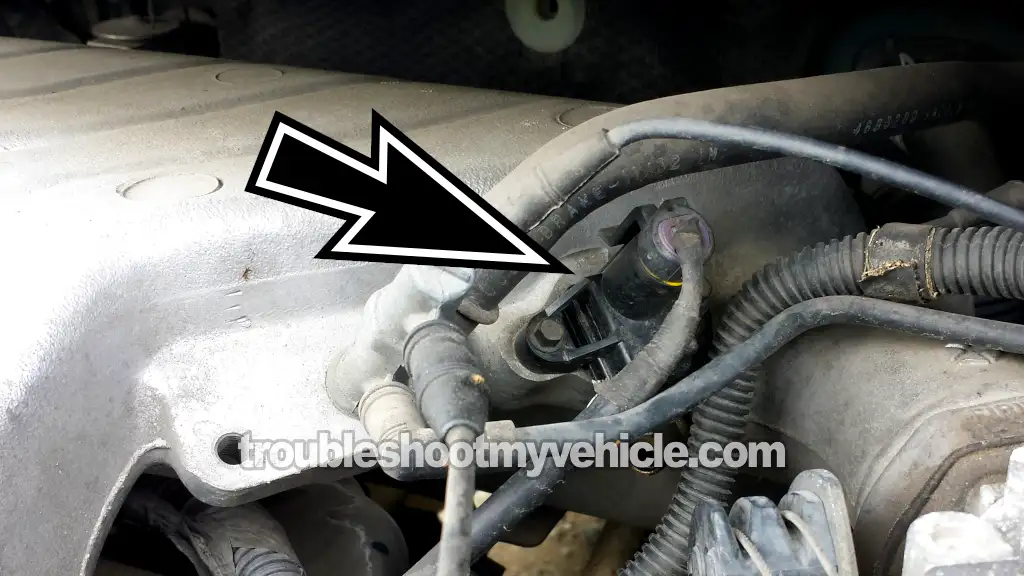

Remove the MAP sensor from the intake manifold.

- 2

Connect the vacuum pump to the MAP sensor. Make sure the hose fits tightly onto both the pump and the sensor's vacuum port.

I used an old spark plug wire boot to make a tight seal between the two. You'll need to get as creative to connect your vacuum pump to the MAP sensor's vacuum inlet port. - 3

Connect the black lead of your multimeter to the battery's negative (-) terminal.

- 4

Switch your multimeter to DC Volts mode.

- 5

Use the red lead to probe the wire that connects to terminal 3 (see the photo above) with an appropriate tool.

IMPORTANT: Don't unplug the sensor —it needs to stay connected to its 3-wire harness.

NOTE: You can either back probe or use a wire-piercing probe to tap into the wire. Not sure how? See the info here: Wire Piercing Probe. - 6

Turn the key to ON, but don't start the engine.

This powers up the MAP sensor with 5 Volts directly from the PCM (that's the fuel injection computer). - 7

With the key ON and no vacuum applied, your meter should read somewhere around 4.5 Volts DC.

- 8

Start applying vacuum using the pump —or just your mouth if that's all you've got.

- 9

You should see the voltage drop. Depending on how much vacuum you pull, it could drop to as low as 1.5 Volts or even lower.

- 10

Let go of the vacuum.

- 11

The voltage should bounce back up to the 4.5 Volt range.

- 12

Repeat steps 8 through 11 a few times.

You should get the same results every time —drop when vacuum's applied, rise when it's released.

Now, let's break down what your readings are telling you:

CASE 1: Voltage dropped steadily when vacuum was applied. That confirms the MAP sensor's doing its job. No further testing needed.

Still getting a MAP sensor trouble code or a check engine light? Go to this section: MAP Sensor Code Won't Go Away.

CASE 2: Voltage stayed flat —no change at all when vacuum was applied. That's usually a dead MAP sensor and it's time to replace it.

Before calling it 100% bad though, we need to double-check that it's actually getting power and Ground. Start with this test: TEST 2: Making Sure The MAP Sensor Is Getting Power.

CASE 3: Multimeter didn't show any voltage whatsoever. That points to a completely non-responsive MAP sensor.

But again, to be certain, let's verify it's got both power and Ground coming in. Head over to this next test: TEST 2: Making Sure The MAP Sensor Is Getting Power.

TEST 2: Making Sure The MAP Sensor Is Getting Power

If you've made it this far, it means TEST 1 confirmed your 3.3L V6 mini-van's MAP sensor isn't putting out a changing voltage signal when you apply or release vacuum.

So now we need to find out if the sensor's even getting power. Without power, it's not gonna do anything at all.

The PCM (Powertrain Control Module —aka your mini-van's fuel injection computer) sends a steady 5 Volts to power the sensor. This voltage runs through the wire that connects to female terminal 2 (see the photo above).

Here's what to do next:

- 1

Disconnect the MAP sensor from its 3-wire plug.

- 2

Connect the black multimeter lead to the battery's negative (-) terminal.

- 3

Put your multimeter in DC Volts mode.

- 4

Turn the key to the ON position —but don't start the engine.

- 5

Use the red lead to probe the front of terminal number 2 (see connector diagram above for exact spot).

- 6

Your multimeter should read somewhere between 4.5 and 5 Volts DC.

Now let's break down what your result means:

CASE 1: You saw a solid 4.5 to 5 Volts. That's exactly what we're looking for. The sensor is getting power like it should.

Next, we've gotta confirm it's also getting a proper Ground. Jump to: TEST 3: Making Sure The MAP Sensor Is Getting Ground.

CASE 2: You didn't get 4.5 to 5 Volts on the meter. First, double-check your test setup and retest.

If everything's good and you're still not seeing voltage, then the MAP sensor isn't the issue —it wont' function without that power.

Figuring out why the 5 Volts are missing is beyond what we're covering here, but you've at least ruled the sensor itself out.

Once you fix whatever's stopping that voltage from reaching the sensor, your MAP-related problems in your 3.3L V6 mini-van should clear up.