In this tutorial, I'll show you how to test the fuel injectors on your V6 Dodge Ram pickup using a multimeter.

It's a quick and easy test that simply involves checking the injector's resistance to find out if it has failed internally and stopped delivering fuel to its cylinder.

Fuel injector failures aren't super common, but when they do happen, you'll definitely notice it: the engine's gonna idle rough or misfire.

Contents of this tutorial:

APPLIES TO: This tutorial applies to the following vehicles:

- 3.9L V6 Dodge Ram 150 Pickup: 1992, 1993.

- 3.9L V6 Dodge Ram 250 Pickup: 1992, 1993.

- 3.9L V6 Dodge Ram 1500 Pickup: 1994, 1995, 1996, 1997, 1998, 1999.

- 3.9L V6 Dodge Ram 2500 Pickup: 1994, 1995, 1996, 1997, 1998, 1999.

WIRING DIAGRAMS:

- Fuel Injector Wiring Diagram (1992-1993 3.9L V6 Dodge Ram Pickup).

- Fuel Injector Wiring Diagram (1994-1995 3.9L V6 Dodge Ram Pickup).

- Fuel Injector Wiring Diagram (1996-1997 3.9L V6 Dodge Ram Pickup).

- Fuel Injector Wiring Diagram (1998-2000 3.9L V6 Dodge Ram Pickup).

Symptoms Of A Bad Fuel Injector

Your Dodge Ram's V6 engine needs three key ingredients in every cylinder to make power:

- Air (compression).

- Fuel.

- Spark.

If any one of those goes missing, that cylinder's going to shut down. When a fuel injector stops working, here are some of the engine performance issues you'll notice:

- Rough idle: The engine shakes while idling.

- Misfiring: You'll feel jerking or hesitation when you accelerate.

- Misfire trouble codes (DTCs): If your pickup is OBD-II (1996+), you'll likely see one of these codes:

- P0300: Random Misfire Across Multiple Cylinders.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

- Sluggish acceleration: The pickup feels slow or underpowered when you press the gas.

- Worse gas mileage: You'll notice a drop in fuel economy.

So, what usually causes a fuel injector to fail? In most cases, it just wears out over time. But that's not the only cause. Here are the three main ways injectors go bad:

- Internal failure: The injector suffers an internal winding failure and completely stops delivering fuel.

- Blockage: It still sprays, but it's clogged, so not enough fuel makes it through or it doesn't spray the fuel in a fine mist (doesn't atomize the fuel correctly).

- Electrical problem: It stays stuck wide open —usually from a fault inside the fuel injection computer or an issue in the injector wiring.

In this tutorial, we're going to focus on fuel injectors that have suffered some sort of internal electrical failure. But, I'm also gonna explain a diagnostic strategy to pin-point a clogged fuel injector.

Where To Buy The Fuel Injector And Save

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Not sure if the above fuel injector fits your particular Dodge Ram pickup? Don't worry, once you get to the site, they'll make sure it fits by asking you the particulars of your vehicle. If it doesn't fit, they'll find you the right one.

Fuel Injector Resistance Specifications

| Year | Engine | Resist. |

|---|---|---|

| 1992 | 3.9L | 12.5-16.5 Ohms |

| 1993-1997 | 3.9L | 13.3-15.7 Ohms |

| 1998-1999 | 3.9L | 10-16 Ohms |

NOTE: All resistances at: 68°F/20°C

TEST 1: Fuel Injector Resistance Test

The steps below assume that you're going to test all six fuel injectors —mostly because they're easy to get to. But if you'd rather not check every single one, that's OK.

That said, if you're only planning to test one injector, I'd still recommend checking at least two others. That way, you'll have a solid reference point to compare resistance values when you're done.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

IMPORTANT: Make sure the engine is completely cold (ambient temp) before testing injector resistance. The readings need to be taken at room temperature (whatever ambient temp is around you is fine too). If the engine's been running, give it time to cool down fully.

Let's get testing:

- 1

Disconnect the fuel injector from its connector.

- 2

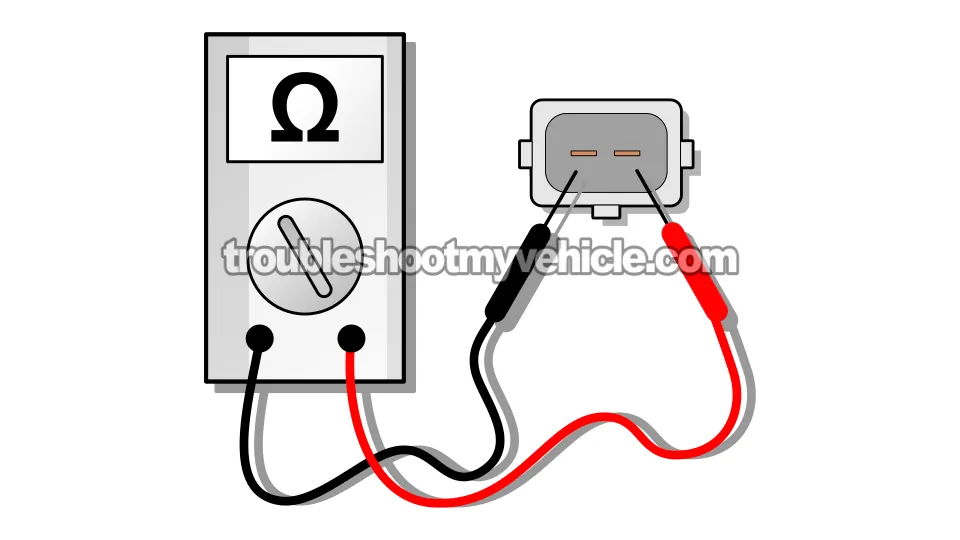

Set your multimeter to the Ohms (Ω) setting.

- 3

Measure the resistance across the injector's two terminals.

You're aiming for a reading that falls within spec: Fuel Injector Resistance Specifications. - 4

Write down the resistance value.

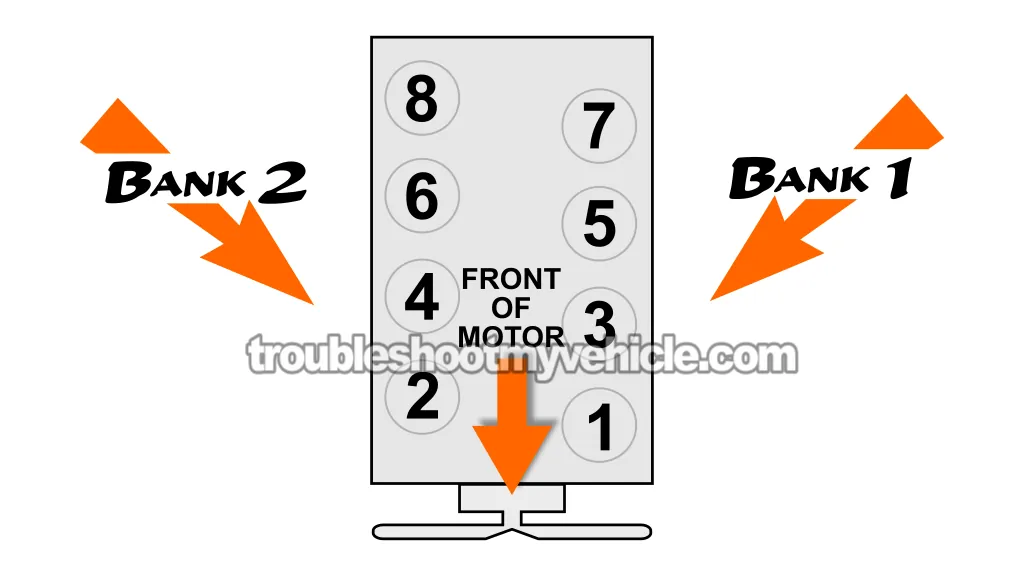

Be sure to label it with the correct cylinder number. See image 2 of 2 to help you ID the cylinder. - 5

Repeat steps 1–4 for the remaining injectors.

Keep track of each one by cylinder so you can compare readings later.

Here's what your results are telling you:

CASE 1: All six injectors are reading within the correct resistance range. That means none of them are shorted out or open internally.

However, even if resistance checks out, one or more could still be clogged. For help diagnosing that, head over to: Fuel Injector Diagnostic Strategy.

CASE 2: One or more injectors show resistance that's way off from the spec. Double-check the reading by testing it again.

If the reading is still off after retesting —and it's clearly different from the others— that injector's shot and needs to be replaced.

Fuel Injector Diagnostic Strategy

After years of troubleshooting a ton of fuel injector problems and misfires, I've put together a go-to test strategy that really works to nail down the exact source of the issue. In this section, I'll show you the fastest way I've found to figure out which injector is acting up.

This is a simple, step-by-step approach that'll help you figure out if your Dodge Ram's rough idle or misfire is being caused by a bad injector —or something else entirely. And the best part? You won't need any expensive tools to get it done.

Here's the approach I use to troubleshoot fuel injectors and misfires:

1.) CHECK FUEL INJECTOR SPRAY:

I remove the fuel injector and attach it to a DIY fuel injector cleaner tool and visually check if the injector is spraying fuel.

With this method, I can confirm right off the bat if the injector is glogged or bad. I've written a step-by-step tutorial that help you with this and you can find here:

2.) PROCESS OF ELIMINATION METHOD:

- Step 1: Identify which cylinder isn't firing.

- This is the most critical step. If you've got a 1996 or newer OBD-II pickup, grab a basic code reader and pull the trouble codes —they'll usually point right to the misfiring cylinder.

- If you're working with an older OBD-I pickup, you can go old-school and run a manual cylinder balance test. That's my favorite method for hunting down misfires on these engines.

- Step 2: Make sure that cylinder has spark.

- Use a spark tester on the plug wire for the misfiring cylinder and crank the engine. If you see spark, it's firing properly.

- Also check the spark plug and boot for oil contamination —oil-soaked parts can prevent spark from reaching the cylinder.

- While you're at it, remove the spark plug and check for cracks or carbon tracks. These are easy to miss but will cause a cylinder misfire.

- Here's a real-life example of how carbon tracks cause issues: Carbon Tracks Are A Common Cause Of Ignition Misfires (from easyautodiagnostics.com).

- This ignition coil test guide will help you test the spark plug wires and distributor cap:

- Step 3: If spark checks out, test that cylinder's compression.

- This step is often skipped, but low compression will absolutely cause a dead cylinder. Here's how to run the test:

- Step 4: Use a Noid light to test injector pulse.

- If spark and compression are good, you need to confirm the injector is getting the signal to fire.

- Here's a quick tutorial on how to use a Noid light:

- How To Use A Noid Light And Where To Buy It (from easyautodiagnostics.com).

- Step 5: Swap the injector if everything else passes.

- If you've got a misfiring cylinder that:

- Has spark.

- Shows normal compression.

- Has good resistance and is getting pulse from the computer.

- NOTE: Don't forget to replace the O-rings when doing this. See: Tech Tip: Always Replace Injector O-Rings.

- If you've got a misfiring cylinder that:

- Step 6: Inspect the injector's spray pattern.

- This involves removing the injector and hooking it up to a special tool that lets you see how it sprays. Learn more about this test and the tool here:

At the end of the day, this whole process is simply a process of elimination. You're using these tests to rule out specific components causing a lack of spark or causing a mechanical problem before blaming the injector.

Speaking from experience —following this step-by-step method has saved me from replacing good injectors more than once, and helped me spot the real issue causing the problem.

Tech Tip: Always Replace Injector O-Rings

Any time you remove a fuel injector —whether you're swapping it out for testing or replacing it with a new one— there's one golden rule: never reuse the old O-rings.

Here's the deal: those O-rings are what seal the injector to the fuel rail and keep everything leak-free. But once you pull the injector, those O-rings can get nicked, stretched, or deformed —even if they look okay.

It might seem like no big deal to reuse them, but trust me, it's not worth the risk. A damaged O-ring can lead to a fuel leak —and fuel near hot engine parts or electrical components? That's a disaster waiting to happen.

Here's the right way to do it:

- Always install new O-rings that match your injector and engine application exactly.

- Lightly lube the new O-rings with clean motor oil before installation. This helps the injector go in smoothly and keeps the O-rings from getting pinched or torn.

It only takes a few extra minutes, and it can save you from a major headache —or worse. O-rings are cheap. Fuel leaks and fire damage? Not so much.

More 3.9L V6 Dodge Ram Pickup Tutorials

You can find a complete list of diagnostic tutorials for the full-size Dodge Ram pickups in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The Ignition Coil (1992-2001 3.9L V6 Dodge Ram Pickup).

- How To Test The Intake Air Temp (IAT) Sensor (1992-1997 3.9L V6 Dodge Ram Pickup).

- Testing The Front Oxygen Sensor's Performance (1996-2001 3.9L V6 Dodge Ram Pickup).

- How To Test The MAP Sensor (1992-1996 3.9L V6 Dodge Ram Pickup).

If this info saved the day, buy me a beer!