Interpreting The Results Of The Engine Compression Test

If you got a low compression reading (in TEST 1), the next step is to find out if this compression value is causing a problem.

What you have to do is find out if this low compression value varies by more than 15% of the highest compression value you obtained from your tests.

Why? Because if the low compression value varies by more than 15%, then this cylinder is going to misfire and can be considered ‘dead’.

You can do this one of two ways: You can calculate this 15% difference with pen and paper or you can use my low compression calculator. You can find the low compression calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that my engine compression test produced the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 160 PSI |

| #6 | 165 PSI |

| #7 | 160 PSI |

| #8 | 170 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: "Wet" Engine Compression Test.

TEST 2: "Wet" Engine Compression Test

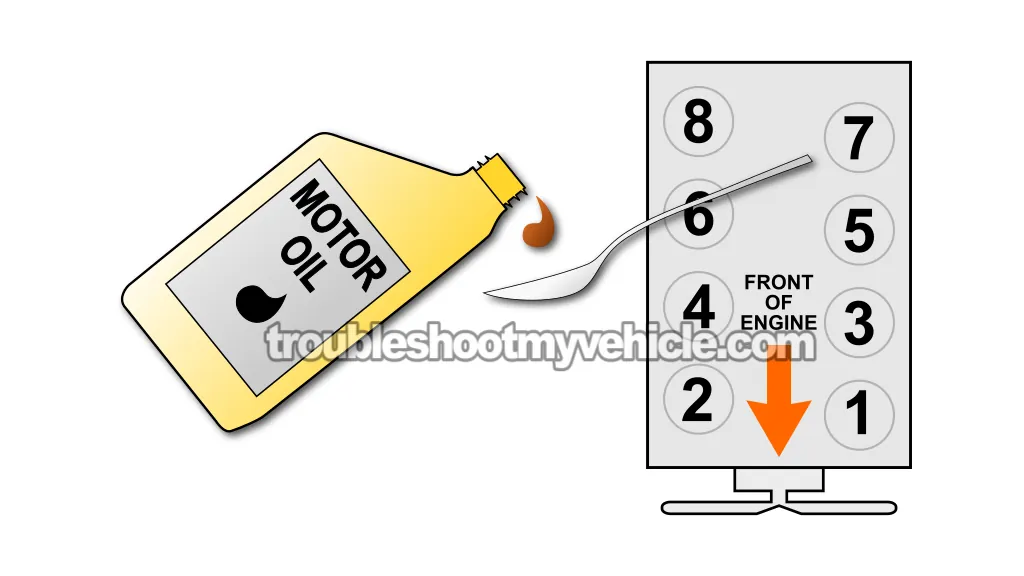

If you've gotten a very low compression reading from any one cylinder, the next step is to add a little bit of engine oil (to that cylinder) and re-check its compression to see if the compression pressure will go up or not.

Adding engine oil and checking the cylinder's compression is known as a ‘Wet’ compression test. This ‘Wet’ compression test will help you determine if the piston rings or cylinder head valves are the ones causing the low or no compression reading you obtained in TEST 1.

The amount of oil you're gonna' add is about 2 tablespoons. If the piston rings are worn (and the cause of the low compression reading), this oil will cause your compression tester to record a higher compression value.

Now, since oil could never help seal the cylinder head valves, if the compression value does not go up (from the previous one), then you'll know that the problem lies in the cylinder head valves.

OK, this is what you need to do:

- 1

Add oil to the cylinder.

- You should add about 2 tablespoons of oil.

- Remember, you're only adding oil to the cylinder or cylinders that reported low or no compression in the dry compression test.

- 2

Install the compression tester.

- Once again, hand-tighten the compression tester.

- 3

Crank the engine when all is ready.

- 4

Once the needle on your compression tester stops climbing, have your helper stop cranking the engine.

- 5

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before).

2.) The compression value will stay the same.

Let's take a look at what your test results mean:

CASE 1: The compression value shot up. This tells you that the piston compression rings are worn out and thus the problem is in the bottom end.

CASE 2: The compression value stayed the same. This confirms that the problem is in the cylinder head valves.

More 4.7L V8 Dodge Ram Pickup Tutorials

You can find a complete list of tutorials in this index:

Here's a small sample of the 4.7L V8 Dodge Ram pickup tutorials you'll find in the index:

- How To Test The COP Ignition Coils (2002-2007 4.7L V8 Dodge Ram Pickup).

- How To Test The CKP Sensor -P0320, P0335, P0339 (2002-2010 4.7L V8 Dodge Ram Pickup).

- Common Causes Of Spark Plug Failure (2002-2009 4.7L V8 Dodge Ram Pickup).

- How To Check For Vacuum Leaks With Carb Cleaner Spray (2002-2009 4.7L V8 Dodge Ram Pickup).

If this info saved the day, buy me a beer!