The distributor pickup coil is a critical part of the ignition system. If it isn't working right, the ignition coil isn't gonna spark and the fuel injectors aren't gonna spray fuel —and that means the engine isn't starting.

The good news? Testing the distributor pickup coil on the 1989 to 1991 Dodge Ram van with a 5.2L or 5.9L V8 is actually pretty simple!

Now, just so you know —on these '89 to '91 models, the pickup coil takes care of both camshaft position (CMP) and crankshaft position (CKP) signals. It's not like the 1992 to 2003 setup where the CKP sensor is mounted separately on the bell housing. Everything's built into the pickup coil on these earlier models.

Contents of this tutorial:

- Symptoms Of A Bad Distributor Pickup Coil.

- What The Distributor Pickup Coil Does.

- Circuit Descriptions Of The Distributor Pickup Coil.

- Where To Buy The Distributor Pickup Coil.

- TEST 1: Testing The Pickup Coil Signal.

- TEST 2: Making Sure The Distributor Pickup Coil Has 8 Volts.

- TEST 3: Making Sure The Distributor Pickup Coil Has Ground.

- More 5.2L, 5.9L V8 Dodge Ram Vans Diagnostic Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram B150 Van 5.2L V8: 1989, 1990, 1991.

- Dodge Ram B250 Van 5.2L V8: 1989, 1990, 1991.

- Dodge Ram B250 Van 5.9L V8: 1989, 1990, 1991.

- Dodge Ram B350 Van 5.9L V8: 1989, 1990, 1991.

IGNITION SYSTEM WIRING DIAGRAMS:

- Ignition System Circuit Wiring Diagram (1989 5.2L, 5.9L V8 Dodge Ram Van).

- Ignition System Circuit Wiring Diagram (1990-1991 5.2L, 5.9L V8 Dodge Ram Van).

OTHER CMP SENSOR TESTS:

- How To Test The Camshaft Position Sensor (1992-1995 5.2L, 5.9L V8 Dodge Ram Van).

- How To Test The Camshaft Position Sensor (1996-1997 5.2L, 5.9L V8 Dodge Ram Van).

- How To Test The Camshaft Position Sensor (1998-2003 5.2L, 5.9L V8 Dodge Ram Van).

Symptoms Of A Bad Distributor Pickup Coil

Generally, when the pickup coil starts failing or quits altogether, the fuel injection computer sets one of these diagnostic trouble codes:

- Code 11: No Crankshaft Reference Signal Detected During Cranking.

- Code 54: No Fuel Sync Signal Detected.

Besides a trouble code, you'll see one or more of the following issues:

- Engine turns over but doesn't start: The engine cranks alright, but doesn't start since the FI computer isn't activating the ignition coil or injectors.

- Random stalling: It might run fine for a while, then suddenly shut off—especially while idling or driving at low speed.

- Check Engine Light (CEL): If Code 11 or 54 gets stored, the CEL will light up to warn you that the computer has lost the distributor signal.

- Rough idle or misfiring: A weak or inconsistent signal messes with spark and fuel timing. That can make the engine idle unevenly or misfire under load.

- Hard start (hot or cold): If the pickup coil signal comes and goes, the engine might eventually start —but only after several attempts.

- Hesitation or weak acceleration: Bad timing from a faulty signal makes the engine hesitate, especially when you hit the gas. Acceleration can feel jerky or underpowered.

What The Distributor Pickup Coil Does

The distributor pickup coil generates the signal the fuel injection computer needs to manage fuel injection and spark —whether you're cranking or already driving.

Let's break down exactly what it does:

- Creates the timing reference signal:

- While the engine turns, the pickup coil produces a digital ON/OFF signal for the fuel injection computer.

- This signal tells the computer which cylinder is on the compression stroke and how fast the engine is spinning (RPM).

- No signal? No spark, no fuel —nothing.

- Controls ignition and fuel injection timing:

- The fuel injection computer uses this reference signal to activate the ignition coil and injectors at the right time.

- If that signal drops or disappears, the engine cranks, but you get zero spark and no fuel spray.

- De facto crankshaft position sensor:

- This V8 engine doesn't use a separate crankshaft position sensor like newer ones do.

- The pickup coil handles all timing and position data the fuel injection computer needs to keep things running right.

Circuit Descriptions Of The Distributor Pickup Coil

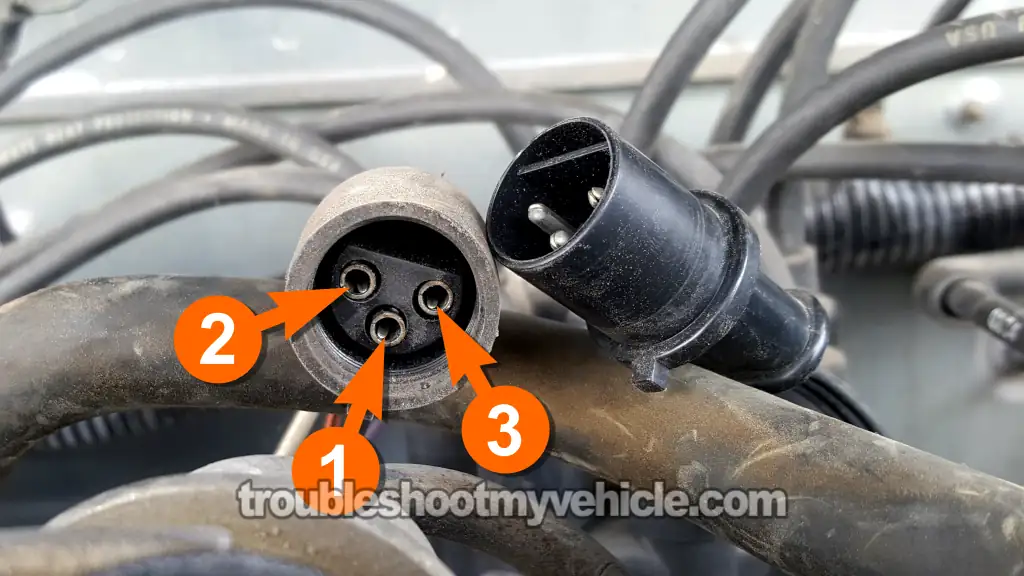

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Orange (ORG) | Power (8 Volts DC) |

| 2 | Black with light blue stripe (BLK/LT BLU) | Sensor Ground |

| 3 | Tan with yellow stripe (TAN/YEL) | Pickup Coil Signal |

Where To Buy The Distributor Pickup Coil

The following links will help you comparison shop for the distributor pickup coil. I think you'll save a few bucks:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Testing The Pickup Coil Signal

As the engine cranks or runs, the distributor pickup coil sends out a pulsing voltage signal. When the signal is ON, it reads 5 Volts DC. When it's OFF, it drops to 0 Volts.

The cool thing is —you can watch that voltage switch between 5 and 0 Volts using a standard multimeter. That's exactly how we're gonna test it.

When the pickup coil fails, it usually gets stuck on one voltage and doesn't switch, even while the engine is spinning.

In the first test, we'll hook into the signal wire from the pickup coil and check if the voltage keeps flipping back and forth between 5 and 0 Volts like it's supposed to.

The wire we're gonna tap into for this signal check is the tan with yellow stripe (TAN/YEL) wire. That's the one that carries the ON/OFF signal straight from the pickup coil to the FI computer.

IMPORTANT: Leave the pickup coil plugged into its engine wiring harness connector during the test. You'll need to back probe the wire or use a wire-piercing probe to measure the CMP voltage right inside the wire without disconnecting anything. Here's what one looks like (and where to buy it): Wire Piercing Probe.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Here's how to test it step by step:

- 1

Connect the black multimeter lead directly to the battery's negative (-) terminal.

- 2

Unplug the ignition coil's electrical connector. This part matters —don't skip it. It's an important safety step.

NOTE: Leave the distributor cap right where it is. That helps keep the pickup coil locked in position. - 3

Switch your multimeter over to DC voltage mode.

- 4

Attach the red lead to the tan with yellow stripe (TAN/YEL) wire coming from the pickup coil connector.

NOTE: Don't unplug the pickup coil. You won't get a reading unless it's still connected to the harness.

CRANKING ENGINE WITH THE STARTER:

- 5

Once you've got the meter hooked up, have someone crank the engine for a few seconds.

- 6

Keep an eye on the meter —the voltage should toggle between 5 and 0 Volts DC while the engine is turning over.

NOTE: If there's no switching at all, do steps 5 and 6 below under "CRANKING ENGINE MANUALLY".

CRANKING ENGINE MANUALLY:

- 5

Grab a 1/2-inch ratchet and socket and turn the crankshaft pulley by hand.

- 6

As you slowly rotate it, the multimeter should bounce back and forth between 5 and 0 Volts DC.

Here's what your results mean:

CASE 1: You saw the voltage flip between 5 and 0 Volts. That's what we're after.

This tells you the pickup coil is working. If the engine still won't start, the pickup coil isn't the cause.

CASE 2: Voltage stayed fixed —no switching between 5 and 0 Volts DC. That's a strong sign the pickup coil is shot.

But before swapping it out, double-check that it's getting both power and Ground. That's what comes next: TEST 2: Making Sure The Distributor Pickup Coil Has 8 Volts.