I'm gonna walk you through how to test the throttle body temperature sensor on the 1989-1991 TBI fuel-injected V8 Dodge Ram van.

All you need is a basic multimeter —no fancy nor expensive diagnostic tools required. With the two resistance tests I'm gonna show you, you'll know if the TB temp sensor is working or if it's toast.

Contents of this tutorial:

- Symptoms Of A Bad Throttle Body Temperature Sensor.

- What Does The Throttle Body Temperature Sensor Do?

- Important Initial Checks.

- Where To Buy The TB Temp Sensor And Connector.

- TEST 1: Cold Temperature Resistance Check.

- TEST 2: Hot Temperature Resistance Check.

- More 5.2L, 5.9L V8 Dodge Ram Van Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram B150 Van 5.2L, 5.9L V8: 1989, 1990, 1991.

- Dodge Ram B250 Van 5.2L, 5.9L V8: 1989, 1990, 1991.

- Dodge Ram B350 Van 5.9L V8: 1989, 1990, 1991.

OTHER IAT SENSOR TESTS:

- How To Test The Intake Air Temp (IAT) Sensor (1992-1997 5.2L, 5.9L V8 Dodge Ram Van).

- How To Test The Intake Air Temp (IAT) Sensor (1998-2003 5.2L, 5.9L V8 Dodge Ram Van).

Symptoms Of A Bad Throttle Body Temperature Sensor

A throttle body temp sensor failure will cause the check engine light to illuminate and log this code:

- Code 23: Throttle Body Temp Sensor Voltage Too Low Or Too High.

But that's not all —it's gonna mess with how your engine runs, especially after it's been warmed up and you try to fire it up again while it's still hot.

Here are the usual signs of a failing throttle body temp sensor:

- Hard start: Tough time starting after a quick stop —like when you stop for gas or run into a store.

- Rough idle: Shaky idle right after a warm restart.

- Engine stall: Engine cuts out right after restarting when it's hot.

- Surging or hesitation: Jerky acceleration or sluggish response during a hot start.

- Extended engine cranking: Cranks longer than normal after shutting it down warm.

You might notice that it fires up fine on a cold morning, but acts weird when it's hot out —or once it's been running for a while. That's a dead giveaway that the sensor's feeding the computer the wrong info about fuel system temperature.

When this sensor fails, it throws off the fuel injection computer (Single Board Engine Controller —SBEC). It may interpret the throttle body as cold when it's hot —or hot when it's not. That mismatch disrupts the air/fuel mixture, especially during hot restarts when vaporized fuel creates unstable starting conditions.

What Does The Throttle Body Temperature Sensor Do?

This sensor's bolted right into the throttle body. Its job? Measure how hot the throttle body gets after the engine's been running. That becomes real important when you shut the engine off and then try to start it again after a short break.

Once the engine shuts off, heat rises up and soaks into the throttle body. That heat raises the fuel temperature, making it easier to vaporize —which can lead to rough starts, shaky idle, or even stalling when you start it back up.

The fuel injection computer watches this sensor closely. If it sees the throttle body's hot, it tweaks the fuel delivery during startup —usually by making it richer— so the engine starts easily, without stumbling.

This sensor also serves a secondary role, as the system lacks a dedicated intake air temperature sensor. When the engine computer needs to estimate the temperature of the incoming air, it relies on the throttle body temperature sensor to provide a substitute input and help maintain a proper air/fuel mixture.

Important Initial Checks

Before beginning any testing procedures on the throttle body temperature sensor, perform the following preliminary visual inspections:

- Examine the sensor's wiring harness for any visible damage, such as frayed, cracked, or missing insulation.

- Inspect the connector for signs of wear or physical damage. Verify that the small U-shaped metal retaining clip (lock clip) is still secured in place.

- Visually check the sensor itself. The upper portion is plastic and can easily fracture or separate from the metal base if impacted or overtightened.

Missing Metal Locking Clip: On these older Dodge vans, the TB temp sensor connector uses a metal locking clip to maintain a secure connection —similar to the clips used on the fuel injectors of the same generation.

If the clip is missing or if the connector is cracked or damaged, it may not hold proper contact with the sensor terminals. This can lead to intermittent signal loss, particularly under high-temperature and high-vibration conditions in the engine bay.

In such cases, the connector should be replaced with a new pigtail to ensure a stable electrical connection. Replacement pigtails are inexpensive and simple to install. A reliable option is the WALKER PRODUCTS 270-1034.

Frayed Wires: Wire fraying typically occurs when the insulation deteriorates, exposing the copper strands beneath. This is a common issue on aging harnesses in these vehicles.

Exposed wires can lead to short-circuits or signal interference, resulting in erratic temperature readings or an illuminated check engine light.

Check out this real-world example to see what it looks like:

- IAT Sensor Wire Insulation Problem And Wires Shorted Together (credit: easyautodiagnostics.com).

Here's how to fix this kind of issue:

- If the wires are badly frayed or the damage is right near the connector, go ahead and replace the whole connector assembly.

- If it's just a small spot and further down the wire, you can wrap it with electrical tape as a quick fix to keep things stable for now.

NOTE: Tape is only a band-aid. If you want long-term reliability, replace anything that's worn out —connector, wires, or both.

Where To Buy The TB Temp Sensor And Connector

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

TEST 1: Cold Temperature Resistance Check

To begin our TB temp sensor diagnostic, we're gonna remove the throttle body temperature sensor from the throttle body and perform a resistance check (using a multimeter).

If the sensor has failed, you'll usually see one of the following readings:

- Open circuit: The multimeter will display "OL" (infinite resistance), indicating a break in continuity within the sensor.

- Short circuit: The multimeter will show "0 Ohms", confirming an internal short between the sensor's terminals.

IMPORTANT: For the resistance measurement to be valid, the sensor must be at ambient temperature (approximately room temperature). If the engine's been running, let it cool off fully before you get started.

NOTE: Need a multimeter or thinking about upgrading? Here's the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Here's how to do the test step by step:

- 1

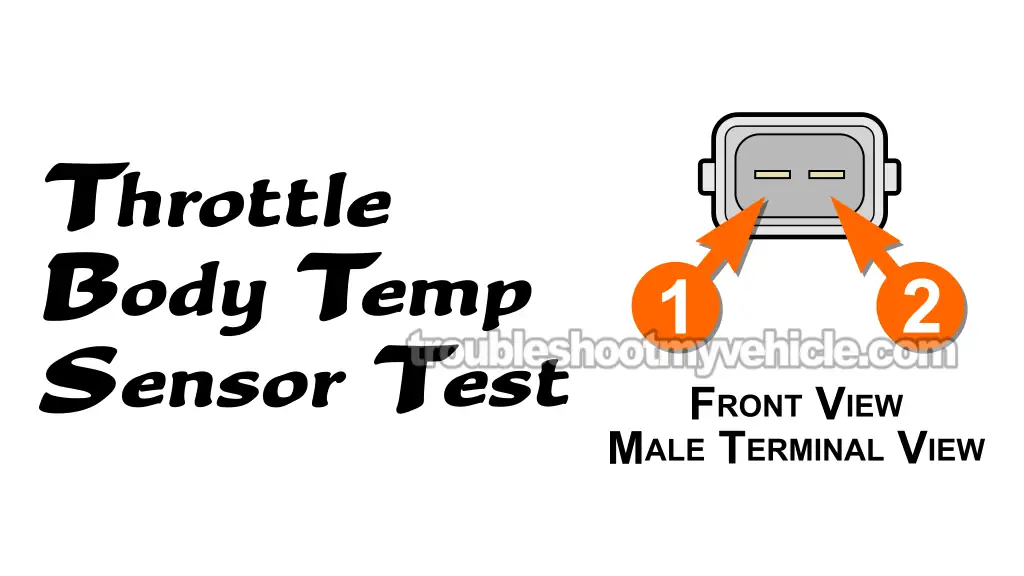

Unplug the TB temp sensor from its 2-wire connector.

NOTE: Check the connector —inspect it to see if it's broken and that it still has it U-shaped metal clip. - 2

Remove the TB temp sensor out of the throttle body.

NOTE: Be careful. The plastic top breaks easy. - 3

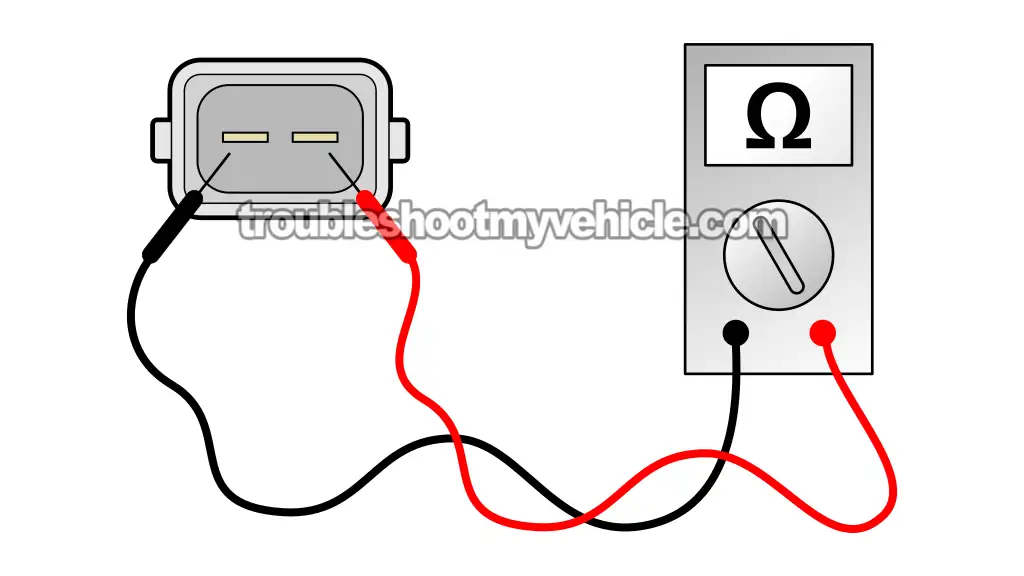

Turn your multimeter to its Ohms (Ω) setting.

- 4

Test the sensor's resistance by placing the multimeter leads on the two male terminals.

At room temp, the reading should land between: 5.6 to 14.6 K Ohms.

Now, let's figure out what those readings mean:

CASE 1: The multimeter reads 0 Ohms. That confirms the sensor is shorted inside —replace it.

CASE 2: The multimeter shows OL (infinite resistance). That means there's no internal connection —sensor's dead and needs to be replaced.

CASE 3: The resistance falls outside the expected range. This usually means the TB temp sensor's no good.

We can double-check that it's bad, before replacing it, by doing one more test. Go to: TEST 2: Hot Temperature Resistance Check.

CASE 4: The resistance is right where it should be. If that's what you got, the TB temp sensor is working fine.

We can double-check that it's good by doing one more test. Go to: TEST 2: Hot Temperature Resistance Check.