TEST 2: Hot Temperature Resistance Check

Alright, now that you've done the cold resistance check in TEST 1, it's time to heat things up and see if the sensor's resistance drops like it should.

At around 200°F, this sensor should read somewhere between 400 and 1,500 Ohms. To hit that temp, we're gonna dunk the sensor in boiling water —which boils at 212°F.

If the resistance doesn't fall within that range while it's in the hot water, then yep, the sensor's cooked.

CAUTION: Boiling water can seriously burn you, so follow these safety steps:

- Keep your hands away from the sensor and wires while they're hot —don't touch anything bare-handed.

- Only dunk the metal sensing tip in the water. Leave the electrical connector dry.

- Use long jumper wires with insulated alligator clips so you don't have to get your hands close to the hot pot. Need to buy some? —Jumper Wires With Insulated Alligator Clips (at: amazon.com).

- Don't run this test with the sensor in place on the throttle body —this is an off-car test.

- Let the sensor cool down completely before picking it up or putting it away.

Alright, let's get this test started:

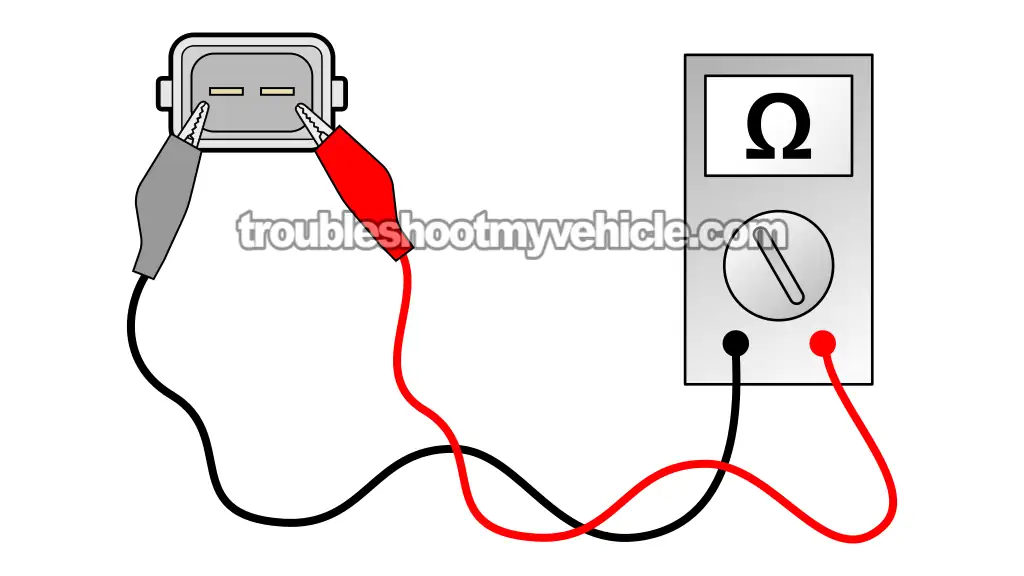

- 1

Connect your multimeter leads to the sensor's two terminals.

IMPORTANT: Use jumper wires with alligator clips to connect the multimeter test leads to the sensor's terminals. This is an important safety precaution so your hands stay far from the hot water or heated surfaces during the test. - 2

Switch your multimeter to the Ohms (Ω) setting.

- 3

Boil a small pot of water on the stove or a hot plate.

A kitchen thermometer helps here —make sure the water's sitting at 200–212°F (93–100°C). - 4

Dip just the metal tip of the sensor into the boiling water.

CAUTION: Keep the plastic top and electrical contacts out of the water.

IMPORTANT: Use tongs or suspend the sensor with wire—don't hold it by hand under any circumstances. - 5

Watch the resistance reading on your multimeter.

With the sensor in the hot water, the resistance should drop into the 400 to 1500 Ohms range. - 6

Take the sensor out and let it cool all the way down before touching it or putting it back on the engine.

Let's interpret your test results:

CASE 1: You're seeing 0 Ohms. That means the sensor's shorted out internally. Replace it.

CASE 2: The reading shows OL (infinite resistance). That means the sensor's open inside —it's bad and needs to go.

CASE 3: The resistance falls outside the expected range. That's a clear sign the sensor's not doing its job —time to replace it.

CASE 4: The resistance lands within spec. That's exactly what you want. The sensor passed this test.

If it also passed TEST 1, then the sensor itself is in good shape. If you're still seeing that trouble code, the real issue might be in the wiring between the connector and the FI computer.

More 5.2L, 5.9L V8 Dodge Ram Van Tutorials

You can find a complete list of tutorials for the 5.2L/5.9L V8 Dodge Ram Van in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Test The MAP Sensor (1989-1990 5.2L, 5.9L V Dodge Ram Van).

- How To Test The TPS (1989-1990 5.2L, 5.9L V8 Dodge Ram Van).

- How To Test Engine Compression (1989-2003 5.2L, 5.9L V8 Dodge Ram Van).

- How To Test For A Blown Head Gasket (1989-2003 5.2L, 5.9L V8 Dodge Ram Van).

If this info saved the day, buy me a beer!