The crankshaft position (CKP) sensor is an easy 3-wire Hall-Effect sensor to test with a multimeter, no scan tool needed!

In this tutorial, I'll explain the whole testing process, step-by-step. With your test results, you'll quickly find out if the CKP sensor is toast and causing your Dodge Ram pickup's engine no-start problem.

Contents of this tutorial:

- Important Tips And Suggestions.

- How The CKP Sensor Works.

- CKP Sensor Connector Pinout.

- Where To Buy The CKP Sensor And Save.

- TEST 1: Checking The CKP Signal With A Multimeter.

- TEST 2: Making Sure The CKP Sensor Has Power.

- TEST 3: Making Sure The CKP Sensor Has Ground.

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 1500 Pickup 5.2L V8: 1998, 1999, 2000, 2001.

- Dodge Ram 2500 Pickup 5.2L V8: 1998.

- Dodge Ram 1500 Pickup 5.9L V8: 1998, 1999, 2000, 2001, 2002, 2003.

- Dodge Ram 2500 Pickup 5.9L V8: 1998, 1999, 2000, 2001, 2002.

- Dodge Ram 3500 Pickup 5.9L V8: 1998, 1999, 2000, 2001, 2002, 2003.

WIRING DIAGRAMS:

- Ignition System Wiring Diagram (1998-2000 5.2L, 5.9L V8 Dodge Ram Pickup).

- Ignition System Wiring Diagram (2001 5.2L, 5.9L V8 Dodge Pickup).

- Ignition System Wiring Diagram (2002 5.9L V8 Dodge Ram Pickup).

- Ignition System Wiring Diagram (2003 5.9L V8 Dodge Ram Pickup).

IGNITION SYSTEM TESTS:

- How To Test The Ignition Coil (1992-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

- How To Test The Camshaft Position Sensor (1998-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

ENGINE NO-START TESTS:

Important Tips And Suggestions

TIP 1 → On-Car Test: We're gonna check the CKP sensor right where it sits on the transmission bell housing. You don't have to pull it out to get this test done.

TIP 2 → Turn the engine by hand (not with the starter motor): To only way to get an accurate reading (with a multimeter) that'll clearly show whether the sensor's good or bad, is to crank the engine by hand.

This part's key —if you use the starter motor to turn over the engine, the results aren't gonna tell you much.

When I say turning the engine over by hand, I mean grabbing a 1/2-inch ratchet and the right socket to manually turn the crankshaft pulley.

TIP 3 → Always check for spark first: Always remember this: if you already checked for spark and the ignition coil is sparking, the CKP sensor's doing its job.

Getting spark means the CKP sensor is alive and kicking. In that case (spark present), running this sensor test won't really add anything helpful.

This tutorial will help you check for spark:

How The CKP Sensor Works

The crankshaft position sensor (CKP) sits on the transmission's bell housing. From there, it reads the notches on the flywheel as the engine cranks or runs. Here's a more detailed breakdown:

- CKP signal: The flywheel's got 8 notches spaced 45° apart. As each one slides past the CKP sensor, it triggers a pulse —8 pulses for every full engine turn— and sends them straight to the fuel injection computer.

- Purpose: Those pulses help the computer track crankshaft position and engine speed (RPM). It teams up that info with the CMP sensor's signal to control when spark and fuel injection happen.

- No CKP signal, no-start: If the computer doesn't see those CKP pulses, it kills the Auto Shutdown (ASD) relay and the fuel pump relay. That cuts off power to the injectors and ignition coil —the end result is an engine won't start.

- ON/OFF voltage: As the crankshaft turns, the CKP sensor flips between ON and OFF signals. "ON" means you'll see 5 Volts DC, and "OFF" means it drops to 0 Volts.

- Testing: The awesome part is you can catch that 5V-to-0V flip with a multimeter —and that's exactly how we're gonna test it.

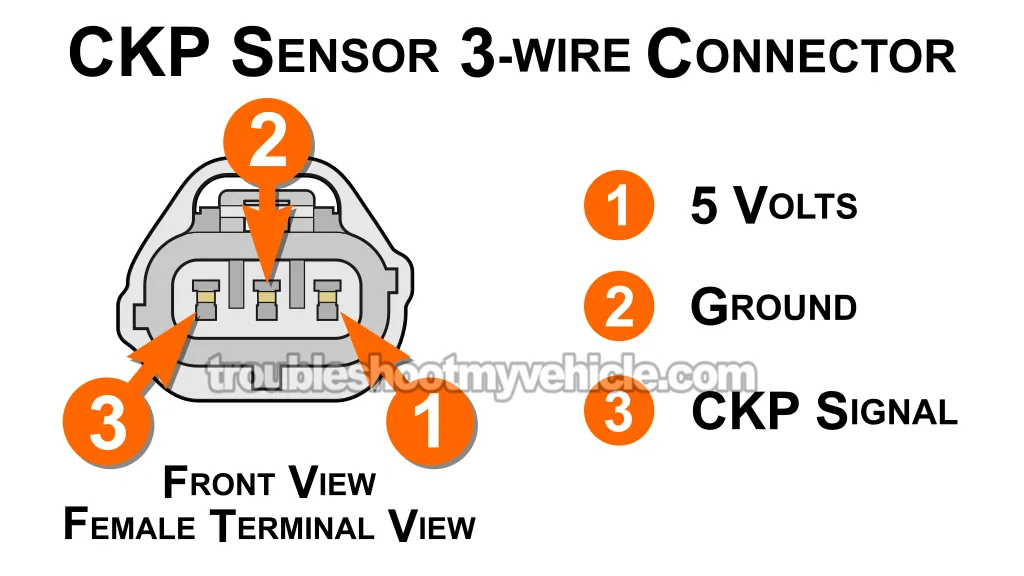

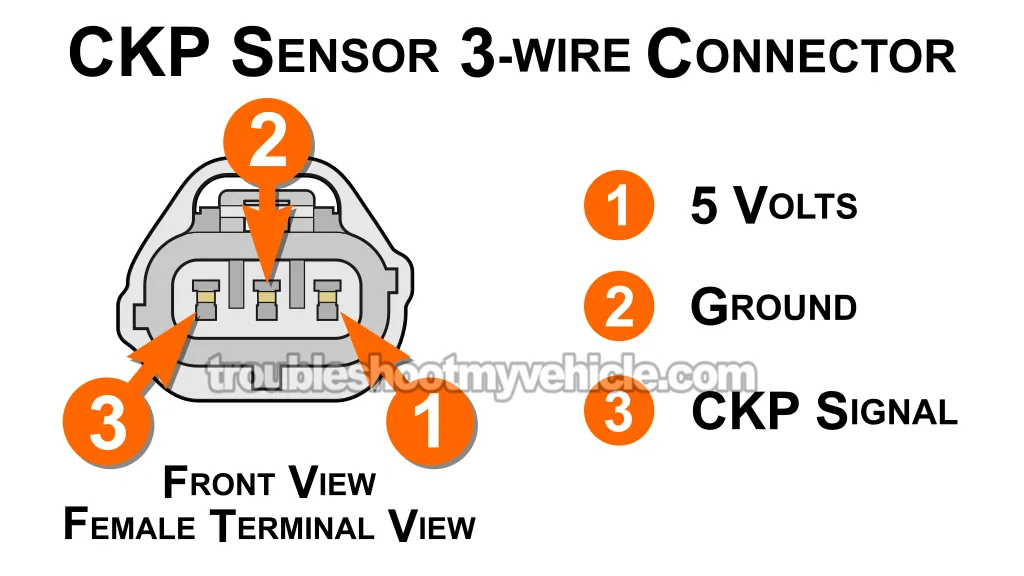

CKP Sensor Connector Pinout

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Violet with white stripe (VIO/WHT) | 5 Volts DC |

| 2 | Black with light blue stripe (BLK/LT BLU) | Sensor Ground |

| 3 | Grey with black stripe (GRY/BLK) | CKP Signal |

Where To Buy The CKP Sensor And Save

If you're not sure if the above CKP sensors fit your particular vehicle, don't worry. Once you get to the site, they'll make sure that it fits and if it doesn't, they'll ask the particulars of your specific Dodge to find you the right one.

TEST 1: Checking The CKP Signal With A Multimeter

The very first thing you gotta do is check if the CKP sensor's sending an ON/OFF signal through its signal wire.

The signal wire you're after is the grey with black stripe (GRY/BLK) wire coming out of the CKP sensor's engine harness connector.

Since the sensor needs to stay plugged in to read the CKP voltage signal, you'll have to tap into that GRY/BLK wire.

You've got two ways to do it: either back-probe the connector or use a wire-piercing probe. You can see an example of this tool and where to buy it here: Wire Piercing Probe Tool Review (Power Probe PWPPPPP01).

IMPORTANT: Like I mentioned earlier, you don't need to remove the CKP sensor to test it —and you really SHOULDN'T. If you do, you'll throw off its air gap calibration.

Put simply: if you pull the sensor out and bolt it back in, the flywheel's reluctor ring will slam into it and wreck it.

NOTE: Need to buy a multimeter or an upgrade? This is the one I have and use: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Alright, let's jump in:

- 1

Unplug the ignition coil from its electrical connector. This is a must-do safety step —don't skip it before you move forward.

- 2

Clamp the black multimeter lead onto the battery's negative (-) post.

- 3

Turn the ignition key to the ON position (but don't crank the engine). This powers up the CKP sensor so you can test it properly.

- 4

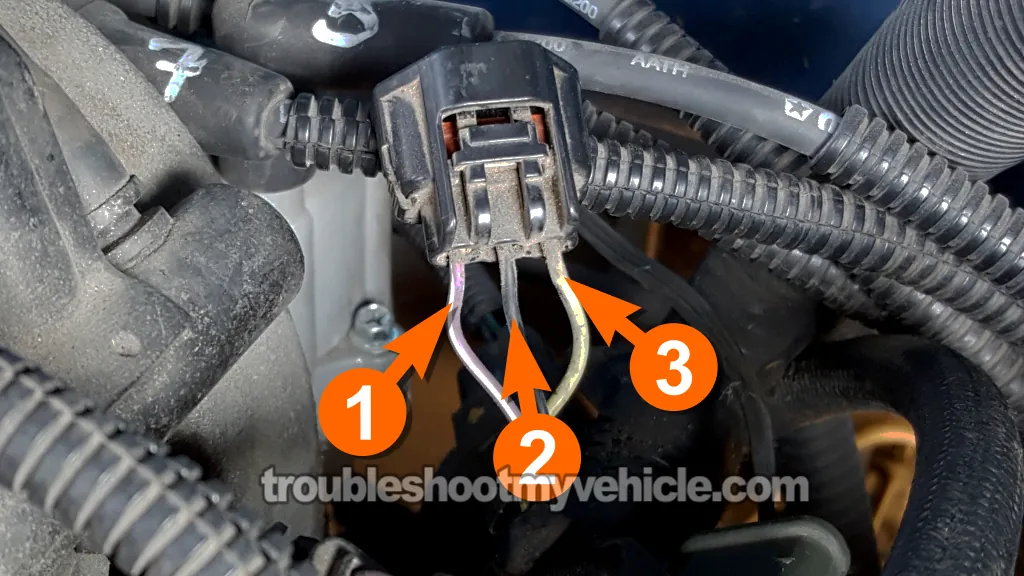

Locate the CKP sensor connector.

Once you find it, peel back any plastic wire loom or electrical tape covering the CKP sensor's three wires. You just need enough cleared space to easily tap into the wires for testing. - 5

Switch your multimeter to Volts DC mode.

- 6

Attach the red multimeter lead to the GRY/BLK wire at the CKP sensor harness connector.

That's the wire going into terminal number 3 of the CKP connector —same one shown in the diagram above.

NOTE: Remember, you've gotta keep the CKP sensor plugged in while doing this test. - 7

Have a helper slowly crank the crankshaft pulley by hand (clockwise) while you keep an eye on the multimeter.

NOTE: No starter motor here —hand-cranking only! Using the starter will skew your readings. - 8

Watch for the multimeter to flip between 0 and 5 Volts DC as the pulley turns.

OFF is 0 Volts, ON is 5 Volts. Make sure your helper turns the crank smoothly and steadily so you can catch the voltage switching clearly.

NOTE: You should catch 8 flips per full revolution of the crankshaft pulley. Each flip happens when one of the flywheel's notches passes under the CKP sensor while you're turning the engine by hand.

Now, let's go over what your results mean:

CASE 1: You saw the multimeter switching between ON and OFF (5 Volts and 0 Volts). That's exactly what you wanna see —your CKP sensor's working right.

Since the CKP sensor is doing its job, you'll have to keep chasing down the real cause of the no-start. Your next diagnostic step should be testing the CMP sensor:

CASE 2: You didn't see the multimeter flip at all while hand-turning the crank pulley. This confirms the CKP sensor isn't sending the signal the PCM needs to fire spark and inject fuel.

About 95% of the time, that means the CKP sensor's shot. Swapping it out usually brings the engine back to life. But —not always.

So before replacing it, double-check if the CKP sensor's actually getting power (5 Volts from the PCM). Here's your next step: TEST 2: Making Sure The CKP Sensor Has Power.