Trouble code P0505: Idle Control Malfunction is one of those codes that can really leave you scratching your head. Chances are, you've already replaced the idle air control (IAC) valve —but the code keeps coming back, and the idle still isn't right.

In this tutorial, I'll walk you through the basics of how the IAC valve works, and more importantly, how to test the IAC valve circuits between its connector and the PCM connector —step by step— so you can finally get to the root of the problem.

Everything is explained in plain English, with clear steps you can follow. With the test results you gather, you'll be able to quickly and confidently track down what's really causing the P0505 diagnostic trouble code (DTC).

Contents of this tutorial:

- What Does The IAC Valve Do?

- Symptoms Of A Bad Idle Air Control (IAC) Valve.

- Most Common Causes Of A P0505 Diagnostic Trouble Code.

- IAC Valve Connector Pinout.

- TEST 1: Connector Wiggle Test.

- TEST 2: Checking For Shorted IAC Valve Wires.

- TEST 3: Checking The IAC Valve Wires For A Short To Ground.

- TEST 4: Checking The IAC Valve Stepper Motor Resistance (From PCM Connector).

- What If The PCM Itself Is Bad?

- How To Repair Shorted IAC Wires (Real-World Fix).

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- Dodge Ram 1500 Pickup 5.2L V8: 1996, 1997, 1998, 1999, 2000, 2001.

- Dodge Ram 2500 Pickup 5.2L V8: 1996, 1997, 1998.

- Dodge Ram 1500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

- Dodge Ram 2500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002.

- Dodge Ram 3500 Pickup 5.9L V8: 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

1992-1995 IAC VALVE TESTS:

VACUUM LEAK TESTS:

What Does The IAC Valve Do?

On the Dodge Ram pickup 5.2L/5.9L V8 engines, idle speed is regulated by an idle air control (IAC) valve mounted on the throttle body.

The 4-wire IAC valve has two stepper motors that move a pintle in and out (from its bore), in small steps, to precisely regulate airflow at idle.

This metered amount of air is allowed (by the IAC valve) to bypass the throttle plate and enter the intake when the engine is idling.

This function is especially important when your foot is off the gas pedal and the throttle plate is closed. The engine still needs to maintain a steady idle RPM, and the IAC valve does this by regulating the air bypassing the throttle plate.

The Powertrain Control Module (PCM) is in charge of adjusting the IAC valve to keep the target idle speed steady. It constantly monitors engine conditions and responds to changes in load. For example:

- When electrical or mechanical load increases (like when the headlights or A/C are turned on), the PCM opens the IAC valve further to raise idle speed and prevent stalling.

- During deceleration or when coming to a stop, the PCM uses the IAC valve to "catch" the falling RPM and stabilize it at the correct idle speed so the engine doesn't shut off.

Symptoms Of A Bad Idle Air Control (IAC) Valve

Since the PCM continually monitors the IAC's electrical circuit. If it detects an abnormal voltage or resistance in the IAC motor circuits (e.g. an open or short), or if the idle speed can't reach the commanded value, it will flag code P0505 Idle Control Malfunction and illuminate the check engine light.

Symptoms of an IAC valve system malfunction may include:

- Stalling or very low idle: The only way to keep the engine idling is to keep your foot on the gas pedal otherwise it stalls.

- High or unstable idle speed: Idle RPM can be too high (e.g. ~1500 RPM) or surge up and down unpredictably.

- Rough idle: The engine may run unevenly or rough while idling, especially if a vacuum leak is present.

- Idle RPM is OK but code is present: In some cases the idle feels fine, but the code still sets due to an electrical issue in the idle control circuit.

Most Common Causes Of A P0505 Diagnostic Trouble Code

In a nutshell, since the PCM uses the IAC valve to control idle airflow (and therefore engine idle RPM), and it constantly monitors RPM whenever the engine is running, any issue with this system (mechanical, electrical, or airflow-related) can cause the PCM to trigger the P0505 Idle System Malfunction diagnostic trouble code (DTC).

Potential causes of a P0505 code include:

- IAC valve has failed: These valves are built to last, but like any moving part, they wear out. The valve is made up of 2 stepper motors coils, and one or both can fail. Other failures include: internally jammed pintles or excessive carbon buildup can all cause failure.

- IAC motor connector is damaged: The connector and/or the female terminals may be corroded, loose, or broken, preventing proper electrical contact.

- One or more IAC valve circuits are open or shorted to Ground: This is a very common issue. This means one of the wires to the IAC valve is either broken (open) or touching metal (shorted to Ground) where it shouldn't. When this happens, communication between the PCM and IAC valve is interrupted.

- One or more IAC circuits are shorted to voltage: Also very common. This usually happens when a wire in the IAC circuit rubs against another IAC wire and they short together. Since one wire is powered and another is a Ground, the Ground wire picks up unintended voltage, throwing off the PCM's ability to control the IAC valve properly.

- PCM has failed: In rare cases, one of the two IAC driver circuits inside the PCM itself fails, preventing the PCM from controlling the IAC valve at all.

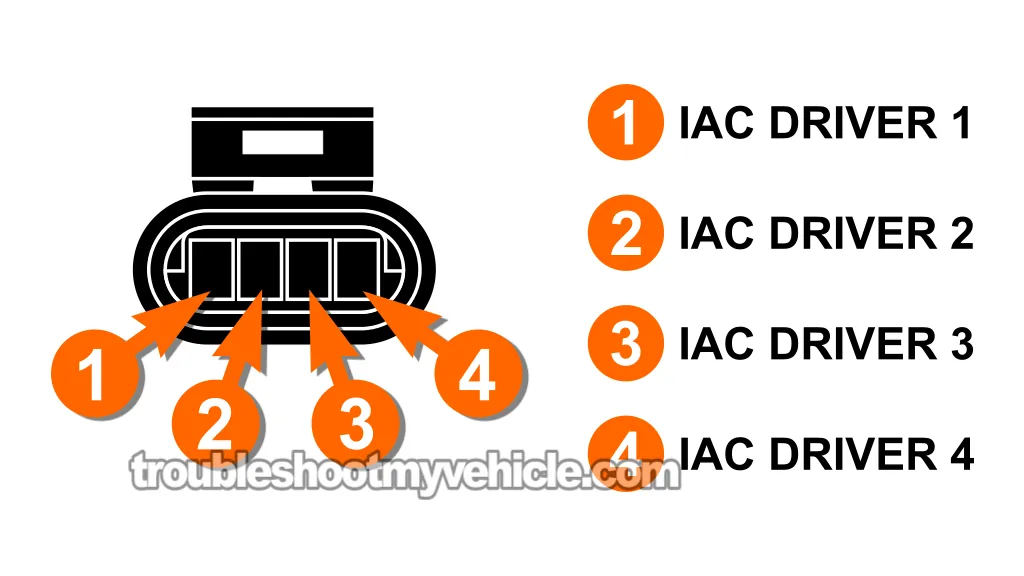

IAC Valve Connector Pinout

| 1996-2001 IAC Connector Pinout | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | grey with red stripe (GRY/RED) | IAC Driver 1 |

| 2 | yellow with black stripe (YEL/BLK) | IAC Driver 2 |

| 3 | brown with white stripe (BRN/WHT) | IAC Driver 3 |

| 4 | violet with black stripe (VIO/WHT) | IAC Driver 4 |

NOTE: The violet with white stripe (VIO/WHT) wire is also referred to as the purple with white stripe (PPL/WHT) wire.

| 2002-2003 IAC Connector Pinout | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | brown with white stripe (BRN/WHT) | IAC Driver 1 |

| 2 | yellow with black stripe (YEL/BLK) | IAC Driver 2 |

| 3 | grey with red stripe (GRY/RED) | IAC Driver 3 |

| 4 | violet with black stripe (VIO/WHT) | IAC Driver 4 |

TEST 1: Connector Wiggle Test

Over time, the metal terminals inside the IAC valve connector can break away from their wires.

In some cases, the wires themselves may short to each other or develop internal breaks, especially where they bend or exit the connector.

A simple wiggle test can help us uncover these issues. By moving the connector and wiring while the engine is running, we'll check for any signs of intermittent connection (like a stumble, surge, or sudden drop in idle speed) that would point to a wiring or connector fault.

CAUTION: This test is performed with the engine running. Be extremely careful. Keep hands, tools, and clothing away from moving parts such as the fan, belts, and pulleys. Stay alert and take all necessary safety precautions while working under the hood.

Here are the test steps:

- 1

Start the engine.

- 2

Gently wiggle the connector, then the wires coming out of it.

Follow the wires as far as they're visible, wiggling them along their entire accessible length, up to the point where they enter the engine wiring harness. - 3

Wiggling the connector or wiring should have no effect on the engine's idle.

If the idle changes or the engine stumbles, you've found a likely problem spot. - 4

Turn off the engine.

Let's interpret your test result:

CASE 1: Wiggling the connector and/or wiring causes the engine to stumble, surge, or shut off. This means you likely have a loose wire or poor contact inside the connector.

Replace the connector to resolve the issue. If the problem lies in the wiring itself, repair or replace the damaged section.

If you're replacing a section of wire, be sure to solder the new wire in place —do not use butt connectors. Vibration and heat can cause butt connectors to loosen over time, leading to intermittent faults. While the following tutorial section focuses on replacing an entire IAC circuit from the PCM to the connector, it includes tips that apply equally well to repairing a short section near the connector: How To Repair Shorted IAC Wires (Real-World Fix).

CASE 2: Wiggling the connector and its wiring has no effect, and the idle remains steady. This suggests the connector and its wiring are in good shape.

Let's move on to checking continuity of the wires. Go to: TEST 2: Checking For Shorted IAC Valve Wires.

CASE 3: The engine doesn't start, or starts and stalls right away. In this case, the problem may be more than just the connector. You could be dealing with a completely failed IAC valve or a deeper wiring or PCM issue.

Your next step is: TEST 2: Checking For Shorted IAC Valve Wires.

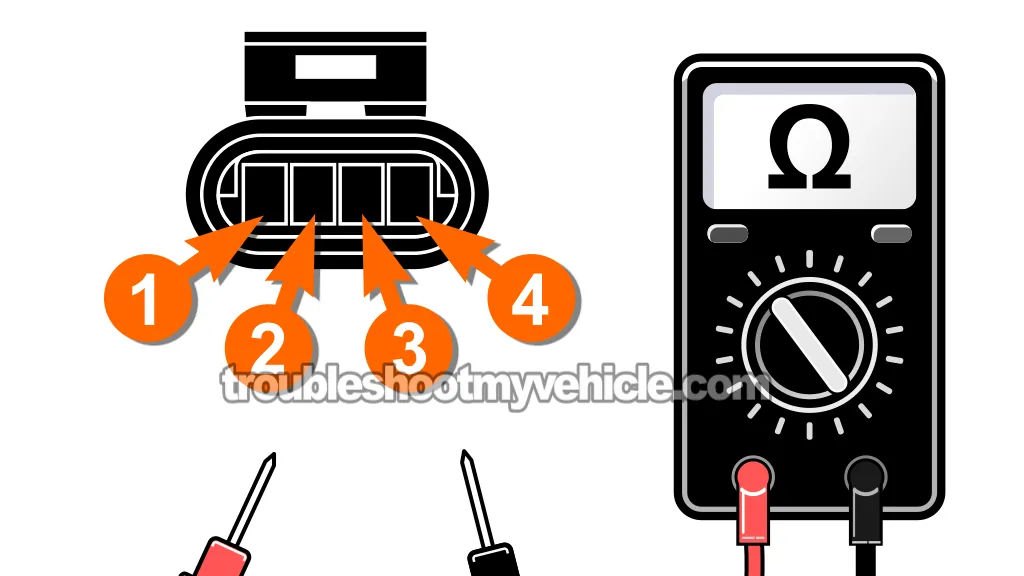

TEST 2: Checking For Shorted IAC Valve Wires

This next test checks whether any of the IAC valve wires are shorted together.

Each of the four IAC valve circuits runs independently from the PCM to the IAC valve. None of these wires should have continuity with one another.

If they do, it means there's an internal short (usually from melted insulation, crushed wiring, or corrosion) and the PCM won't be able to control the IAC valve correctly.

To do this test, we'll disconnect both the IAC valve and the PCM connectors (all 3 of them), then check for continuity between each of the terminals at the IAC valve connector.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Let's get going:

- 1

Turn the key OFF and disconnect the battery.

NOTE: This ensures you don't accidentally short anything or damage the multimeter. - 2

Disconnect the IAC valve connector and all 3 PCM connectors.

You'll need full access to both ends of the circuit so there's no interference from the PCM itself. - 3

Set your multimeter to Ohms mode.

NOTE: Don't use Continuity mode (if your multimeter has one). - 4

At the IAC valve connector, place one multimeter lead on Terminal 1.

- 5

Use the other multimeter lead to probe Terminals 2, 3, and 4 one by one.

- 6

The meter should show no continuity (infinite resistance or the letters OL) between Terminal 1 and the others.

- 7

Repeat this process for the remaining terminals.

Move your first lead to Terminal 2 and check for continuity to 3 and 4. Then repeat for Terminal 3. You're making sure none of the terminals are shorted to one another.

If the multimeter shows low resistance (typically 5 Ohms or less) between any two terminals, that means those wires are shorted together (and that's a problem).

Let's interpret your test result:

CASE 1: Your multimeter shows infinite resistance between all four terminals (no continuity). This is the correct result. The wires are electrically isolated from each other, as they should be.

Let's move on to the next test: TEST 3: Checking The IAC Valve Wires For A Short To Ground.

CASE 2: Your multimeter shows continuity between two or more terminals (low resistance, usually 5 Ohms or less). This means there's a short between wires.

The most common cause is damaged insulation somewhere in the IAC wires in the engine wiring harness. You'll need to repair the shorted wires. See this section for how to do this: How To Repair Shorted IAC Wires (Real-World Fix).

CASE 3: Your readings jump around, or show intermittent continuity as you move the wiring. This points to a partial short or broken wire making intermittent contact.

The most common cause is damaged insulation somewhere in the IAC wires in the engine wiring harness. You'll need to repair the shorted wires. See this section for how to do this: How To Repair Shorted IAC Wires (Real-World Fix).