Getting a diagnostic trouble code 25: Idle Air Control (IAC) Circuits can be frustrating —especially if you've already swapped out the IAC valve and the code just won't go away and the idle still acts up.

In this guide, I'll break down how the IAC valve works, and more importantly, I'll show you how to test the wiring between the IAC valve connector and the fuel injection computer so you can finally figure out what's really going on.

I've written everything with both the absolute beginner and experienced DIYer in mind. By the time you're done testing, you'll be able to zero in on the real cause of that stubborn DTC 25 with confidence.

Contents of this tutorial:

- What Does The IAC Valve Do?

- Symptoms Of A Bad Idle Air Control (IAC) Valve.

- Most Common Causes Of A Diagnostic Trouble Code 25.

- IAC Valve Connector Pinout.

- TEST 1: Connector Wiggle Test.

- TEST 2: Checking For Shorted IAC Valve Wires.

- TEST 3: Checking The IAC Valve Wires For A Short To Ground.

- TEST 4: Checking The IAC Valve Stepper Motor Resistance (From FI Computer Connector).

- What If The PCM Itself Is Bad?

- How To Repair Shorted IAC Wires (Real-World Fix).

- More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

1989-1993:

- Dodge Ram 150 Pickup 5.2L V8: 1992, 1993.

- Dodge Ram 250 Pickup 5.2L V8: 1992, 1993.

- Dodge Ram 150 Pickup 5.9L V8: 1993.

- Dodge Ram 250 Pickup 5.9L V8: 1993.

- Dodge Ram 350 Pickup 5.9L V8: 1993.

1994-2003:

- Dodge Ram 1500 Pickup 5.2L V8: 1994, 1995.

- Dodge Ram 2500 Pickup 5.2L V8: 1994, 1995.

- Dodge Ram 1500 Pickup 5.9L V8: 1994, 1995.

- Dodge Ram 2500 Pickup 5.9L V8: 1994, 1995.

- Dodge Ram 3500 Pickup 5.9L V8: 1994, 1995.

1996-2003 IAC VALVE TESTS:

VACUUM LEAK TESTS:

What Does The IAC Valve Do?

On the 1992-1995 5.2L and 5.9L V8 Dodge Ram pickup engines, the idle speed is controlled by the idle air control (IAC) valve, which is mounted on the rear of the throttle body.

The valve is made up of two small stepper motors, as such it has four wires coming out of its electrical connector (two wires per stepper motor).

These stepper motors, which are control by the fuel injection computer, move a pintle in or out of its bore in tiny steps, allowing for precise control of the airflow at idle.

The valve lets a measured amount of air bypass the closed throttle plate and flow into the intake —when the engine is running.

Since the FI computer constantly monitors engine operating conditions, it adjusts idle RPM through the IAC valve in response to changes in load. For example:

- Letting off the gas or coming to a stop: When you're off the gas and the throttle is shut (whether you're coasting, decelerating, or slowing to a stop) the engine still needs to keep running smoothly. The FI computer uses the IAC valve to manage idle airflow, stabilize RPM, and prevent the engine RPM from dipping too low or shutting off.

- Extra load (like switching on the A/C or headlights): The FI computer responds by opening the IAC valve a bit more. This helps raise the idle speed and keeps the engine from stalling.

Symptoms Of A Bad Idle Air Control (IAC) Valve

The FI computer keeps a close watch on the IAC valve's electrical circuits. If it spots something unusual, such as:

- Voltage or resistance that's out of range due to an open or short-circuit.

- An idle speed doesn't match what it's commanding.

...it'll set Code 25: Idle Air Control (IAC) Circuits and turns on the check engine light (CEL).

When there's a problem with the IAC system, you'll usually see one or more of the following symptoms:

- Stalling or an idle that's too low: You may have to keep your foot slightly on the gas just to keep the engine from dying.

- Idle speed is too high or erratic: The engine might idle around 1500 RPM or bounce up and down unexpectedly.

- Rough idling: The engine runs unevenly when idling.

- Idle feels normal, but the code still gets set: Engine idle seems OK, but the PCM detects an electrical fault in the IAC circuit and sets the code anyway.

Most Common Causes Of A Diagnostic Trouble Code 25

Here are some of the most common reasons you might see a Code 25:

- Worn-out IAC valve: Although designed to last, IAC valves can fail over time. Each one has two stepper motor coils —and if either one burns out, the valve won't work right.

- Stuck IAC valve pintle: Over time, carbon buildup on the pintle can block its movement or prevent it from seating correctly in the air bypass passage, causing the FI computer to lose its ability to fine-tune idle RPM.

- Damaged IAC connector: If the connector or its terminals are broken, loose, or damaged in any way, proper electrical flow to the valve is interrupted.

- Open or shorted IAC circuit (to Ground): This is a common problem. One or more of the IAC valve wires might be broken (open) or touching metal somewhere (short to Ground), which blocks the FI computer from communicating with the IAC valve correctly.

- IAC wiring shorted to power: Also a common issue. If two IAC wires rub together (one carrying voltage and the other a Ground) the Ground wire can pick up voltage it shouldn't, causing the FI computer to lose control of the IAC valve.

- FI computer failure: Rare, but it happens. One of the internal circuits in the FI computer that controls the IAC valve may stop working, making it impossible for the computer to move the valve at all.

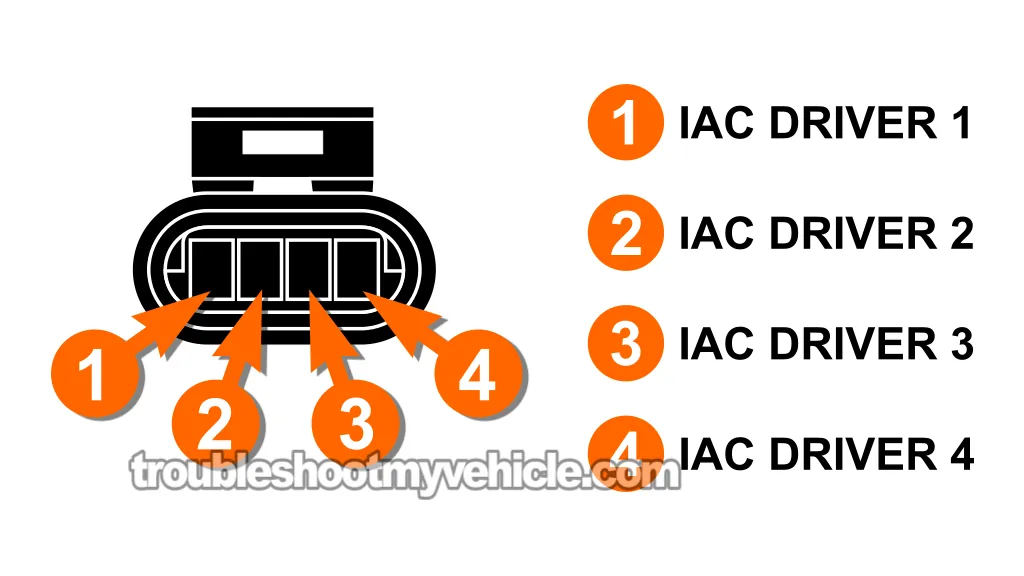

IAC Valve Connector Pinout

| 1996-2001 IAC Connector Pinout | ||

|---|---|---|

| Pin | Wire Color | Description |

| 1 | Grey with red stripe (GRY/RED) | IAC Driver 1 |

| 2 | Yellow with black stripe (YEL/BLK) | IAC Driver 2 |

| 3 | Brown with white stripe (BRN/WHT) | IAC Driver 3 |

| 4 | violet with black stripe (VIO/WHT) | IAC Driver 4 |

NOTE: The violet with white stripe (VIO/WHT) wire is also referred to as the purple with white stripe (PPL/WHT) wire.

TEST 1: Connector Wiggle Test

As time passes and the engine wiring harness ages, it's not uncommon for the metal terminals inside the IAC valve connector to loosen or even break off from their wires.

Sometimes the IAC valve 4 wires, where they exit the connector, can short together or develop internal breaks that aren't visible from the outside.

One easy way to catch these problems is by doing a wiggle test —gently moving the connector (while it's still plugged into the IAC valve) and the wiring around it while the engine is running, and watching for any changes like stumbling, surging, or a sudden drop in idle RPM.

If you notice any change in engine idle RPM during the wiggle test, there's a wiring or connector problem.

IMPORTANT SAFETY NOTE: Since this test is done with the engine running, extreme caution is a must. Keep your hands, tools, and clothing far away from moving parts —like the cooling fan, belts, and pulleys. Stay alert and take all safety precautions when working under the hood.

Let's begin the wiggle test:

- 1

Start the engine and let it idle.

- 2

Begin gently wiggling the IAC connector, then the wires attached to it.

Move along the length of the wires, gently flexing them all the way to where they disappear into the main engine harness. - 3

Keep an eye on the engine RPM as you move the wires.

If the idle stays steady, the wiring is likely OK. But if you notice any stalling, RPM drops, or stumbling —you've got a fault in the wiring or connector. - 4

When finished, turn off the engine.

Now, let's go over what your wiggle test results mean:

CASE 1: The engine stumbles, surges, or shuts off when you move the connector or wiring. This usually points to a loose wire or a bad connection inside the IAC connector.

The fix? Replace the connector. If the issue is in the wire itself, repair or replace the affected portion.

NOTE: if you're splicing in a new section of wire, always solder the connection instead of using butt connectors. Heat and vibration under the hood can cause crimped connectors to loosen over time, leading to hard-to-find intermittent problems.

The next section in this guide walks you through replacing an entire IAC circuit —but the techniques shown also apply to repairing just a small section near the connector: How To Repair Shorted IAC Wires (Real-World Fix).

CASE 2: Wiggling has no effect —idle stays stable. That's a good sign. It means both the connector and wiring are working properly.

From here, the next step is to test wire continuity. Jump to: TEST 2: Checking For Shorted IAC Valve Wires.

CASE 3: The engine doesn't start, or it stalls immediately after starting. This may indicate a bigger problem than just the connector —you could be dealing with a fully failed IAC valve, faulty wiring, or even an issue in the FI computer itself.

Your next step is: TEST 2: Checking For Shorted IAC Valve Wires.

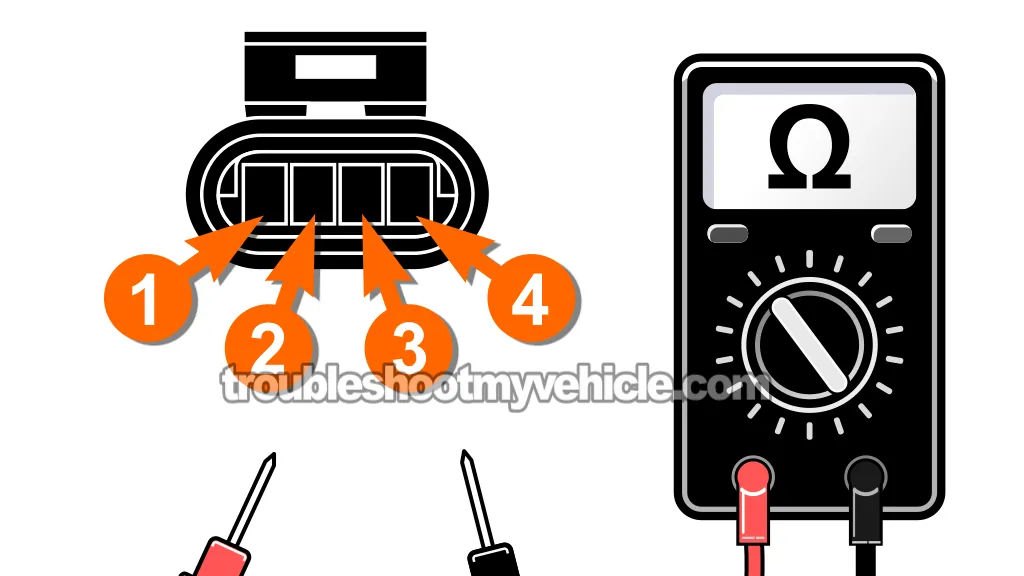

TEST 2: Checking For Shorted IAC Valve Wires

In this next test, we're going to see if any of the IAC valve wires are shorted to each other.

The IAC system has four separate circuits that run from the FI computer to the valve —each wire should be electrically isolated from the others.

If any of these wires show continuity between them, it usually means they've got an short-circuit problem somewhere in the engine wiring harness. When that happens, the FI computer can't properly control the IAC valve.

To run this check, we'll unplug both the IAC valve and the FI computer 60 pin connector. Then, we'll test for continuity between the terminals at the IAC valve connector to make sure none of the wires are shorted together.

NOTE: Don't have a multimeter or need to upgrade yours? This is the one I use and recommend: Tekpower TP8268 AC/DC Auto/Manual Range Digital Multimeter (at: amazon.com).

Here's how to perform the test:

- 1

Switch the ignition OFF and disconnect the battery negative (-) cable from the battery negative (-) post.

NOTE: This helps prevent any accidental shorts or damage to your multimeter during testing. - 2

Unplug both the IAC valve connector and the FI computer's 60 pin connector.

- 3

Switch your multimeter to its Ohms (Ω) setting.

IMPORTANT: Avoid using the continuity (beep) function —it's not as precise for this test. - 4

Place one lead of your multimeter on Terminal 1 of the IAC connector.

- 5

With the other lead, test Terminals 2, 3, and 4 —one at a time.

- 6

You should see no continuity —the meter should read infinite resistance between Terminal 1 and the others.

- 7

Repeat the test for each remaining terminal.

Move your first lead to Terminal 2, then check against Terminals 3 and 4. Do the same for Terminal 3.

If your multimeter reads low resistance —typically 5 Ohms or less —between any two terminals, that means those wires are shorted together.

Here's how to interpret your test results:

CASE 1: Multimeter shows infinite resistance between all terminals. Perfect. That means none of the wires are connected internally —each one is electrically isolated just like it should be.

Now you're ready to move on to the next step: TEST 3: Checking The IAC Valve Wires For A Short To Ground.

CASE 2: You're getting continuity between two or more terminals —a reading of 5 Ohms or less. That tells us the wires are shorted together somewhere.

The most likely culprit? Damaged insulation inside the engine wiring harness. Take a look at this section for the repair steps: How To Repair Shorted IAC Wires (Real-World Fix).

CASE 3: The reading changes as you move the harness —or you see intermittent continuity. That's a sign of a partial short or possibly a wire that's breaking inside the insulation and making occasional contact.

Again, damaged insulation is the usual suspect here. Use the same repair procedure found in this section: How To Repair Shorted IAC Wires (Real-World Fix).