Calculating The Compression Values To See If They Are Within Range

If you've reached this point, then the compression values that you obtained from your compression test in TEST 1 are not similar.

As I mentioned earlier, this could be normal or it could be an indication of an internal engine problem that could be causing a misfire (if your Ford comes equipped with OBD2 , then you'll see one of the following trouble codes: P0300, P0301, P0302, P0303, P0304, P0305 or P0306).

The rule of thumb is that the lowest compression value cannot vary more than 15% from the highest value you recorded. Any cylinder with a compression value lower than 15% of the highest will misfire.

Here's how you can figure this ‘15%’ out:

- Grab a calculator and multiply the highest compression reading that you recorded by 0.15. So, let's say that cylinder #4 gave you the highest reading of 170 PSI. Well 170 X 0.15 gives you 26 (25.5 rounded off).

- Now, the next step is to subtract 26 from 170, which gives us 144 PSI.

- So then, 144 PSI is the lowest possible compression reading that any one of the rest of the engine cylinders can have. Any compression reading below this and that engine cylinder will misfire.

To make better sense of the above calculation, let's say that my 1.6L Toyota produced the following compression test results:

- Cylinder #1 175 PSI.

- Cylinder #2 165 PSI.

- Cylinder #3 160 PSI.

- Cylinder #4 110 PSI.

- Cylinder #5 165 PSI.

- Cylinder #6 165 PSI.

The next step is to do the math: 175 x 0.15= 26, 175-26= 149. So, now I know that cylinder #4 is the one causing the misfire!!

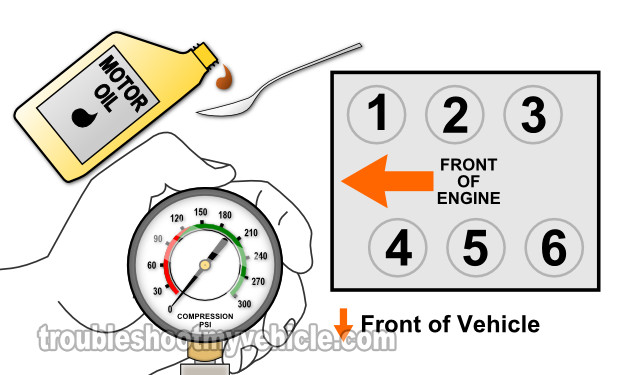

TEST 2: Wet Compression Test

In this test section we're gonna' add a little bit of oil (two tablespoons) to the cylinder that gave you a low compression value test result in TEST 1. This will help us to find out what's causing the low compression value.

To be a bit more specific, what generally provokes a low engine compression (or a 0 PSI) value is worn piston rings or worn cylinder head valves.

Now, if the low compression is due to worn piston rings, then adding oil cause them to seal better and the compression value will shoot up.

If the low compression is due to severely worn or damaged cylinder head valves, then the oil will have no effect on the compression value. In other words, adding oil to the cylinder will not cause a change in the compression value you recorded in TEST 1.

Alright, let's get started:

- 1

Add a tablespoon (or two) of engine oil in the cylinder you need to retest. Use a funnel to make sure that the oil reaches the inside of the cylinder.

- 2

Once you've added the oil, install the compression gauge, and hand tighten it.

- 3

Have your helper crank the engine till the needle stops climbing on the compression gauge.

- 4

You'll see one of two results:

1.) The needle will climb higher than the previous compression number you recorded for this specific cylinder, or...

2.) The needle will not move at all or stay at the same number you recorded earlier.

What ever value your compression tester reads, write it down again. - 5

If you have another cylinder test, repeat steps 1 thru' 4 on it now.

Let's take a look at what test results mean:

CASE 1: The compression value went up after adding motor oil and retesting. This tells you that the low compression problem is due to worn piston compression rings.

Here's why: The motor oil you just added helped the piston rings to create a tighter seal. With the piston rings now sealing the compression inside the cylinder, the compression value on your compression tester went up. This type of test result only happens when the problem is due to worn piston rings.

CASE 2: The compression value DID NOT go up after adding oil and retesting (in other words, it stayed the same). This result tells you that the low compression value registered in this cylinder (in the dry test) is due to worn/damaged cylinder head valves.

If this info saved the day, buy me a beer!